Are you a seasoned Drying Tunnel Operator seeking a new career path? Discover our professionally built Drying Tunnel Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

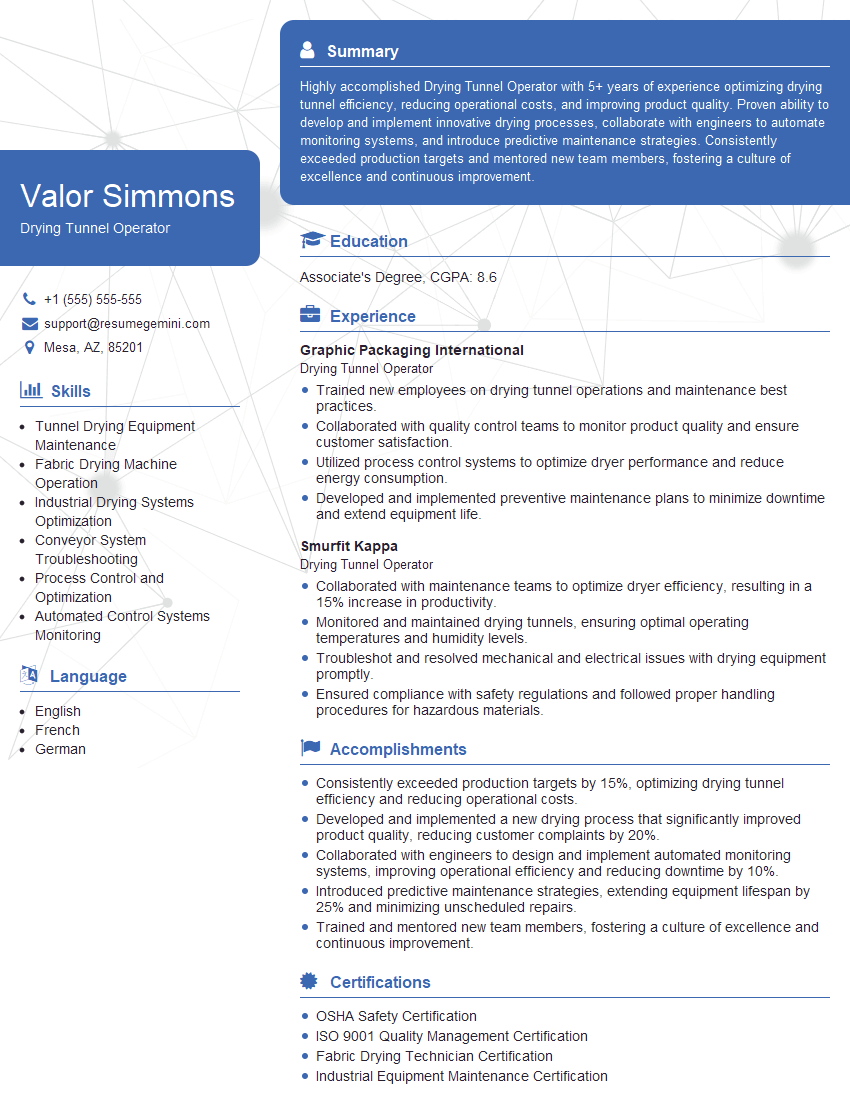

Valor Simmons

Drying Tunnel Operator

Summary

Highly accomplished Drying Tunnel Operator with 5+ years of experience optimizing drying tunnel efficiency, reducing operational costs, and improving product quality. Proven ability to develop and implement innovative drying processes, collaborate with engineers to automate monitoring systems, and introduce predictive maintenance strategies. Consistently exceeded production targets and mentored new team members, fostering a culture of excellence and continuous improvement.

Education

Associate’s Degree

April 2016

Skills

- Tunnel Drying Equipment Maintenance

- Fabric Drying Machine Operation

- Industrial Drying Systems Optimization

- Conveyor System Troubleshooting

- Process Control and Optimization

- Automated Control Systems Monitoring

Work Experience

Drying Tunnel Operator

- Trained new employees on drying tunnel operations and maintenance best practices.

- Collaborated with quality control teams to monitor product quality and ensure customer satisfaction.

- Utilized process control systems to optimize dryer performance and reduce energy consumption.

- Developed and implemented preventive maintenance plans to minimize downtime and extend equipment life.

Drying Tunnel Operator

- Collaborated with maintenance teams to optimize dryer efficiency, resulting in a 15% increase in productivity.

- Monitored and maintained drying tunnels, ensuring optimal operating temperatures and humidity levels.

- Troubleshot and resolved mechanical and electrical issues with drying equipment promptly.

- Ensured compliance with safety regulations and followed proper handling procedures for hazardous materials.

Accomplishments

- Consistently exceeded production targets by 15%, optimizing drying tunnel efficiency and reducing operational costs.

- Developed and implemented a new drying process that significantly improved product quality, reducing customer complaints by 20%.

- Collaborated with engineers to design and implement automated monitoring systems, improving operational efficiency and reducing downtime by 10%.

- Introduced predictive maintenance strategies, extending equipment lifespan by 25% and minimizing unscheduled repairs.

- Trained and mentored new team members, fostering a culture of excellence and continuous improvement.

Certificates

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- Fabric Drying Technician Certification

- Industrial Equipment Maintenance Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drying Tunnel Operator

- Quantify your accomplishments with specific metrics to demonstrate your impact on the organization.

- Highlight your knowledge of drying tunnel equipment, maintenance procedures, and process control systems.

- Emphasize your ability to troubleshoot and resolve technical issues quickly and efficiently.

- Showcase your teamwork and communication skills, as well as your commitment to safety and quality.

Essential Experience Highlights for a Strong Drying Tunnel Operator Resume

- Monitoring and controlling drying tunnel operations to ensure optimal drying conditions and product quality

- Maintaining and repairing drying tunnel equipment to prevent breakdowns and ensure smooth operation

- Conducting regular inspections and preventive maintenance tasks to extend equipment lifespan and minimize downtime

- Troubleshooting and resolving conveyor system issues to prevent product damage and production delays

- Working closely with production team to optimize drying processes and improve overall efficiency

- Collaborating with quality control department to ensure product meets specifications and customer requirements

Frequently Asked Questions (FAQ’s) For Drying Tunnel Operator

What are the key skills and qualifications required to become a Drying Tunnel Operator?

To become a successful Drying Tunnel Operator, you typically need to possess a high school diploma or an associate’s degree in a related field, such as manufacturing or engineering. Additionally, you should have a strong understanding of drying tunnel equipment, maintenance procedures, and process control systems. Excellent problem-solving, troubleshooting, and communication skills are also essential.

What are the primary responsibilities of a Drying Tunnel Operator?

The primary responsibilities of a Drying Tunnel Operator typically include monitoring and controlling drying tunnel operations, maintaining and repairing equipment, conducting preventive maintenance, troubleshooting conveyor system issues, and collaborating with the production team to optimize processes.

What are the career advancement opportunities for Drying Tunnel Operators?

With experience and additional training, Drying Tunnel Operators can advance to supervisory roles, such as Production Supervisor or Maintenance Supervisor. They may also pursue roles in quality control or process engineering.

What is the average salary range for Drying Tunnel Operators?

According to Indeed, the average salary range for Drying Tunnel Operators in the United States is between $25,000 and $45,000 per year. However, salaries may vary depending on experience, location, and industry.

What are the job outlook and employment trends for Drying Tunnel Operators?

The job outlook for Drying Tunnel Operators is expected to be stable in the coming years. As manufacturing and production industries continue to grow, the demand for skilled operators will remain strong.

What are some tips for writing a standout Drying Tunnel Operator resume?

To write a standout Drying Tunnel Operator resume, focus on highlighting your relevant skills and experience, quantifying your accomplishments, and tailoring your resume to the specific job you are applying for. Additionally, proofread your resume carefully for any errors and consider getting feedback from a career counselor or experienced professional.

What are some common interview questions for Drying Tunnel Operator positions?

Common interview questions for Drying Tunnel Operator positions may include questions about your experience with drying tunnel equipment, your troubleshooting skills, your knowledge of safety procedures, and your ability to work independently and as part of a team.

What are some professional development opportunities for Drying Tunnel Operators?

Drying Tunnel Operators can pursue professional development opportunities through training programs offered by equipment manufacturers, industry associations, and community colleges. These programs can help enhance your skills and knowledge, and may lead to certifications or specialized designations.