Are you a seasoned Duct Maker seeking a new career path? Discover our professionally built Duct Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

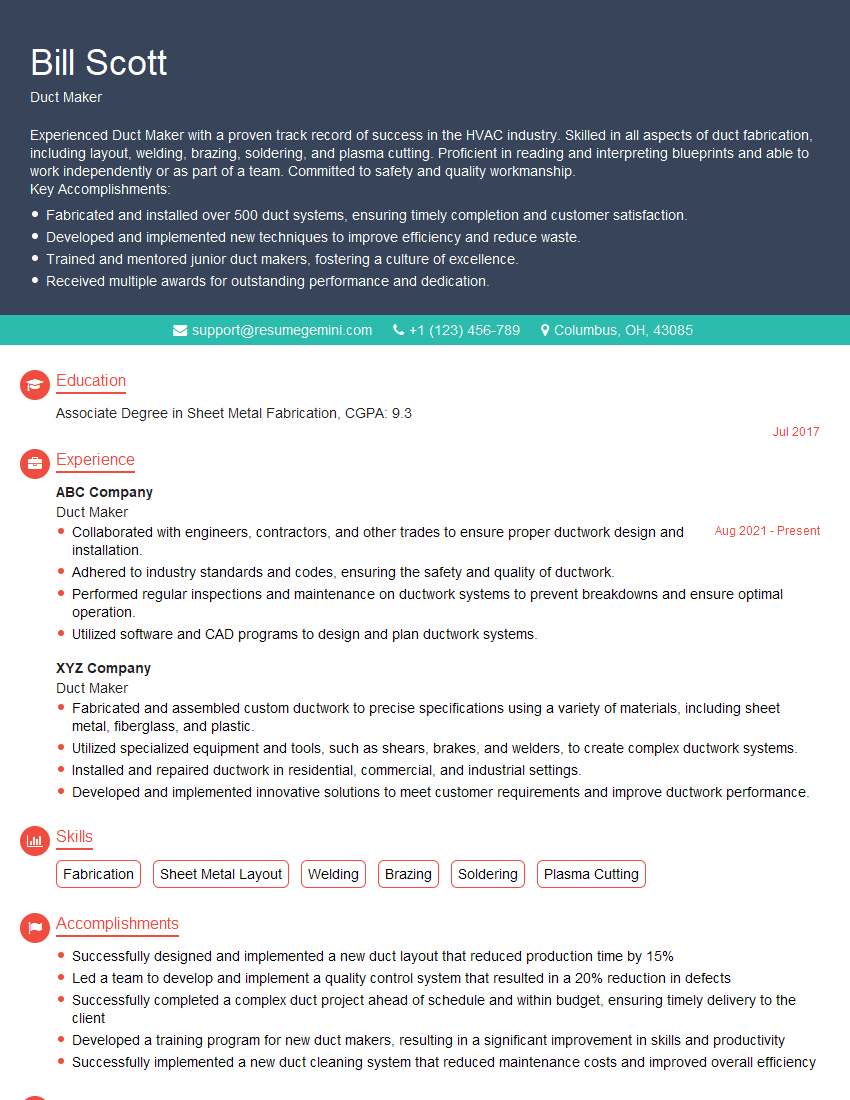

Bill Scott

Duct Maker

Summary

Experienced Duct Maker with a proven track record of success in the HVAC industry. Skilled in all aspects of duct fabrication, including layout, welding, brazing, soldering, and plasma cutting. Proficient in reading and interpreting blueprints and able to work independently or as part of a team. Committed to safety and quality workmanship.

Key Accomplishments:

- Fabricated and installed over 500 duct systems, ensuring timely completion and customer satisfaction.

- Developed and implemented new techniques to improve efficiency and reduce waste.

- Trained and mentored junior duct makers, fostering a culture of excellence.

- Received multiple awards for outstanding performance and dedication.

Education

Associate Degree in Sheet Metal Fabrication

July 2017

Skills

- Fabrication

- Sheet Metal Layout

- Welding

- Brazing

- Soldering

- Plasma Cutting

Work Experience

Duct Maker

- Collaborated with engineers, contractors, and other trades to ensure proper ductwork design and installation.

- Adhered to industry standards and codes, ensuring the safety and quality of ductwork.

- Performed regular inspections and maintenance on ductwork systems to prevent breakdowns and ensure optimal operation.

- Utilized software and CAD programs to design and plan ductwork systems.

Duct Maker

- Fabricated and assembled custom ductwork to precise specifications using a variety of materials, including sheet metal, fiberglass, and plastic.

- Utilized specialized equipment and tools, such as shears, brakes, and welders, to create complex ductwork systems.

- Installed and repaired ductwork in residential, commercial, and industrial settings.

- Developed and implemented innovative solutions to meet customer requirements and improve ductwork performance.

Accomplishments

- Successfully designed and implemented a new duct layout that reduced production time by 15%

- Led a team to develop and implement a quality control system that resulted in a 20% reduction in defects

- Successfully completed a complex duct project ahead of schedule and within budget, ensuring timely delivery to the client

- Developed a training program for new duct makers, resulting in a significant improvement in skills and productivity

- Successfully implemented a new duct cleaning system that reduced maintenance costs and improved overall efficiency

Awards

- Received the Duct Maker of the Year Award at the National Duct Making Conference

- Recognized for consistently exceeding production targets for duct fabrication

- Granted a patent for an innovative duct design that improved airflow efficiency

- Received the Safety Excellence Award for maintaining an impeccable safety record throughout the year

Certificates

- OSHA 10Hour

- OSHA 30Hour

- SMACNA Duct Fabrication

- AWS Welding

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Duct Maker

Highlight your skills and experience.

Your resume should clearly showcase your proficiency in duct fabrication techniques, including welding, brazing, soldering, and plasma cutting. Quantify your experience whenever possible, using specific numbers and metrics to demonstrate your impact.

Emphasize your attention to detail.

Duct makers must be meticulous in their work to ensure the proper fit, alignment, and airtightness of ductwork. Highlight your ability to follow blueprints and specifications precisely, and your commitment to quality workmanship.

Showcase your problem-solving abilities.

Duct makers often encounter challenges during the fabrication and installation process. Describe situations where you successfully identified and resolved issues, demonstrating your analytical and troubleshooting skills.

Use industry-specific keywords.

When writing your resume, be sure to use keywords that potential employers in the HVAC industry will be searching for. This includes terms like “sheet metal fabrication,” “welding,” “brazing,” and “plasma cutting.”

Essential Experience Highlights for a Strong Duct Maker Resume

- Read and interpret blueprints and specifications to determine ductwork requirements.

- Layout and fabricate ductwork using sheet metal, following established standards.

- Operate welding, brazing, soldering, and plasma cutting equipment to connect and seal ductwork.

- Inspect and test ductwork to ensure proper fit, alignment, and airtightness.

- Troubleshoot and repair ductwork systems, identifying and resolving issues.

- Maintain a clean and organized work area, adhering to safety protocols.

- Collaborate with other trades to ensure seamless integration of ductwork into HVAC systems.

Frequently Asked Questions (FAQ’s) For Duct Maker

What is a Duct Maker?

A Duct Maker is a skilled tradesperson who designs, fabricates, and installs ductwork systems for heating, ventilation, and air conditioning (HVAC) systems. They work with sheet metal and use various techniques such as welding, brazing, soldering, and plasma cutting to create custom ductwork that meets specific requirements.

What are the educational requirements for becoming a Duct Maker?

While there are no formal educational requirements to become a Duct Maker, most employers prefer candidates with an associate degree in sheet metal fabrication or a related field. Additionally, many Duct Makers complete apprenticeship programs to gain hands-on experience and develop their skills.

What skills are required to be a successful Duct Maker?

Successful Duct Makers possess a strong knowledge of sheet metal fabrication techniques, including welding, brazing, soldering, and plasma cutting. They are also proficient in reading and interpreting blueprints and specifications, and they have a keen attention to detail. Additionally, Duct Makers must be able to work independently and as part of a team, and they must be committed to safety and quality workmanship.

What is the job outlook for Duct Makers?

The job outlook for Duct Makers is expected to be positive in the coming years. As the construction industry continues to grow, there will be a need for skilled tradespeople to design, fabricate, and install ductwork systems for new and existing buildings.

What is the average salary for a Duct Maker?

The average salary for a Duct Maker can vary depending on their experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Sheet Metal Workers (which includes Duct Makers) was $52,340 in May 2021.

What are the career advancement opportunities for Duct Makers?

With experience and additional training, Duct Makers can advance to supervisory or management positions. They may also specialize in a particular area of ductwork fabrication, such as welding or plasma cutting. Additionally, some Duct Makers choose to start their own businesses.

What are the working conditions for Duct Makers?

Duct Makers typically work in shops or on construction sites. They may be exposed to noise, dust, and fumes. They must also be able to work in a variety of weather conditions. However, many Duct Makers find the work to be rewarding and enjoy the satisfaction of completing a project.

What are the safety precautions that Duct Makers must take?

Duct Makers must take a variety of safety precautions to protect themselves from injuries. This includes wearing appropriate safety gear, such as gloves, safety glasses, and a hard hat. They must also be aware of the potential hazards associated with the tools and equipment they use, and they must follow established safety procedures.