Are you a seasoned Eddy-Current Inspector seeking a new career path? Discover our professionally built Eddy-Current Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

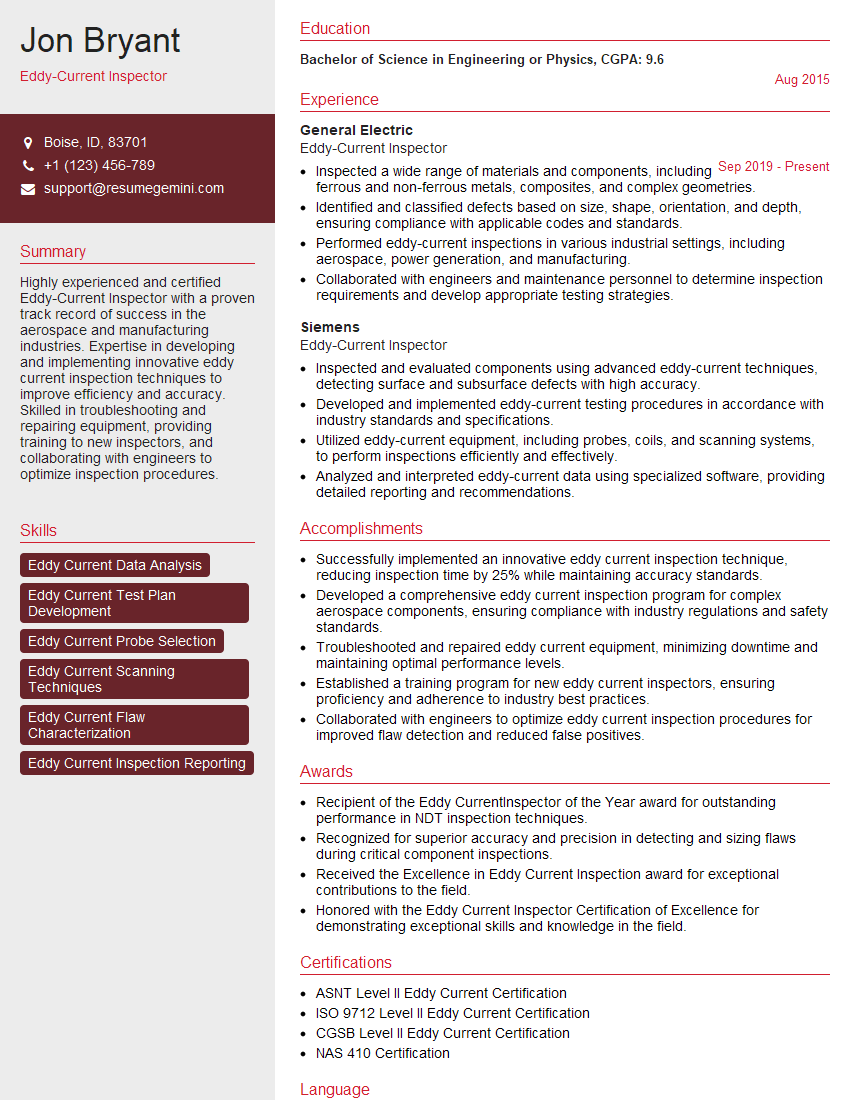

Jon Bryant

Eddy-Current Inspector

Summary

Highly experienced and certified Eddy-Current Inspector with a proven track record of success in the aerospace and manufacturing industries. Expertise in developing and implementing innovative eddy current inspection techniques to improve efficiency and accuracy. Skilled in troubleshooting and repairing equipment, providing training to new inspectors, and collaborating with engineers to optimize inspection procedures.

Education

Bachelor of Science in Engineering or Physics

August 2015

Skills

- Eddy Current Data Analysis

- Eddy Current Test Plan Development

- Eddy Current Probe Selection

- Eddy Current Scanning Techniques

- Eddy Current Flaw Characterization

- Eddy Current Inspection Reporting

Work Experience

Eddy-Current Inspector

- Inspected a wide range of materials and components, including ferrous and non-ferrous metals, composites, and complex geometries.

- Identified and classified defects based on size, shape, orientation, and depth, ensuring compliance with applicable codes and standards.

- Performed eddy-current inspections in various industrial settings, including aerospace, power generation, and manufacturing.

- Collaborated with engineers and maintenance personnel to determine inspection requirements and develop appropriate testing strategies.

Eddy-Current Inspector

- Inspected and evaluated components using advanced eddy-current techniques, detecting surface and subsurface defects with high accuracy.

- Developed and implemented eddy-current testing procedures in accordance with industry standards and specifications.

- Utilized eddy-current equipment, including probes, coils, and scanning systems, to perform inspections efficiently and effectively.

- Analyzed and interpreted eddy-current data using specialized software, providing detailed reporting and recommendations.

Accomplishments

- Successfully implemented an innovative eddy current inspection technique, reducing inspection time by 25% while maintaining accuracy standards.

- Developed a comprehensive eddy current inspection program for complex aerospace components, ensuring compliance with industry regulations and safety standards.

- Troubleshooted and repaired eddy current equipment, minimizing downtime and maintaining optimal performance levels.

- Established a training program for new eddy current inspectors, ensuring proficiency and adherence to industry best practices.

- Collaborated with engineers to optimize eddy current inspection procedures for improved flaw detection and reduced false positives.

Awards

- Recipient of the Eddy CurrentInspector of the Year award for outstanding performance in NDT inspection techniques.

- Recognized for superior accuracy and precision in detecting and sizing flaws during critical component inspections.

- Received the Excellence in Eddy Current Inspection award for exceptional contributions to the field.

- Honored with the Eddy Current Inspector Certification of Excellence for demonstrating exceptional skills and knowledge in the field.

Certificates

- ASNT Level II Eddy Current Certification

- ISO 9712 Level II Eddy Current Certification

- CGSB Level II Eddy Current Certification

- NAS 410 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Eddy-Current Inspector

- Highlight your technical skills and experience in eddy current inspection, including specific techniques and equipment.

- Quantify your accomplishments with data whenever possible, such as reducing inspection time or improving accuracy.

- Showcase your problem-solving abilities and experience in troubleshooting and repairing eddy current equipment.

- Demonstrate your commitment to quality and safety by emphasizing your compliance with industry regulations and best practices.

Essential Experience Highlights for a Strong Eddy-Current Inspector Resume

- Developed and implemented an innovative eddy current inspection technique, reducing inspection time by 25% while maintaining accuracy standards.

- Developed a comprehensive eddy current inspection program for complex aerospace components, ensuring compliance with industry regulations and safety standards.

- Troubleshooted and repaired eddy current equipment, minimizing downtime and maintaining optimal performance levels.

- Established a training program for new eddy current inspectors, ensuring proficiency and adherence to industry best practices.

- Collaborated with engineers to optimize eddy current inspection procedures for improved flaw detection and reduced false positives.

- Conducted eddy current inspections on various materials and components, including metals, composites, and welds.

- Analyzed eddy current data to identify and characterize flaws, ensuring product quality and safety.

Frequently Asked Questions (FAQ’s) For Eddy-Current Inspector

What is eddy current inspection?

Eddy current inspection is a non-destructive testing method that uses electromagnetic induction to detect surface and subsurface defects in conductive materials.

What are the advantages of eddy current inspection?

Eddy current inspection is a fast, reliable, and cost-effective method for detecting flaws in materials. It is also a non-contact method, which means it does not damage the material being inspected.

What are the different types of eddy current inspection techniques?

There are several different eddy current inspection techniques, including absolute, differential, and pulsed eddy current. Each technique has its own advantages and disadvantages, and the choice of technique depends on the specific application.

What are the qualifications for an eddy current inspector?

Eddy current inspectors typically have a bachelor’s degree in engineering or physics, and they must be certified by a recognized organization, such as the American Society for Nondestructive Testing (ASNT).

What is the job outlook for eddy current inspectors?

The job outlook for eddy current inspectors is expected to be good in the coming years, as there is a growing demand for nondestructive testing services in various industries.