Are you a seasoned Efficiency Engineer seeking a new career path? Discover our professionally built Efficiency Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

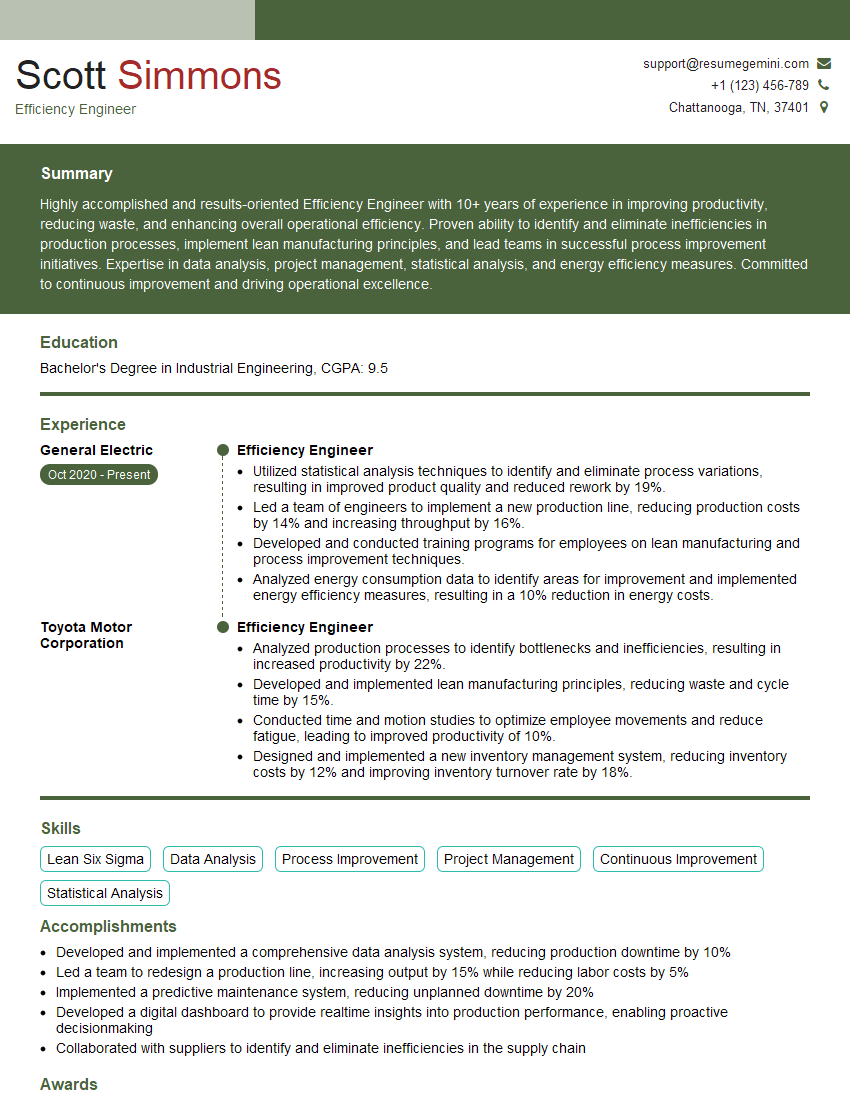

Scott Simmons

Efficiency Engineer

Summary

Highly accomplished and results-oriented Efficiency Engineer with 10+ years of experience in improving productivity, reducing waste, and enhancing overall operational efficiency. Proven ability to identify and eliminate inefficiencies in production processes, implement lean manufacturing principles, and lead teams in successful process improvement initiatives. Expertise in data analysis, project management, statistical analysis, and energy efficiency measures. Committed to continuous improvement and driving operational excellence.

Education

Bachelor’s Degree in Industrial Engineering

September 2016

Skills

- Lean Six Sigma

- Data Analysis

- Process Improvement

- Project Management

- Continuous Improvement

- Statistical Analysis

Work Experience

Efficiency Engineer

- Utilized statistical analysis techniques to identify and eliminate process variations, resulting in improved product quality and reduced rework by 19%.

- Led a team of engineers to implement a new production line, reducing production costs by 14% and increasing throughput by 16%.

- Developed and conducted training programs for employees on lean manufacturing and process improvement techniques.

- Analyzed energy consumption data to identify areas for improvement and implemented energy efficiency measures, resulting in a 10% reduction in energy costs.

Efficiency Engineer

- Analyzed production processes to identify bottlenecks and inefficiencies, resulting in increased productivity by 22%.

- Developed and implemented lean manufacturing principles, reducing waste and cycle time by 15%.

- Conducted time and motion studies to optimize employee movements and reduce fatigue, leading to improved productivity of 10%.

- Designed and implemented a new inventory management system, reducing inventory costs by 12% and improving inventory turnover rate by 18%.

Accomplishments

- Developed and implemented a comprehensive data analysis system, reducing production downtime by 10%

- Led a team to redesign a production line, increasing output by 15% while reducing labor costs by 5%

- Implemented a predictive maintenance system, reducing unplanned downtime by 20%

- Developed a digital dashboard to provide realtime insights into production performance, enabling proactive decisionmaking

- Collaborated with suppliers to identify and eliminate inefficiencies in the supply chain

Awards

- Recognized for outstanding contributions in streamlining production processes, resulting in a 25% efficiency gain

- Received Lean Six Sigma certification for expertise in process improvement methodologies

- Nominated for the National Energy Efficiency Award for innovative energysaving solutions

- Recognized by the industry association for contributions to the advancement of efficiency engineering

Certificates

- Certified Lean Six Sigma Black Belt

- Certified Energy Manager (CEM)

- Registered Professional Engineer (PE)

- Certified Production and Inventory Manager (CPIM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Efficiency Engineer

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Highlight your expertise in lean manufacturing principles and methodologies.

- Showcase your ability to lead and motivate teams in a fast-paced manufacturing environment.

- Emphasize your analytical skills and ability to identify and solve complex operational problems.

- Include relevant certifications, such as Lean Six Sigma or Project Management Professional (PMP), to enhance your credibility.

Essential Experience Highlights for a Strong Efficiency Engineer Resume

- Analyze production processes to identify bottlenecks and inefficiencies, and develop and implement solutions to optimize operations.

- Conduct time and motion studies to optimize employee movements and reduce fatigue, leading to improved productivity.

- Utilize statistical analysis techniques to identify and eliminate process variations, resulting in improved product quality and reduced rework.

- Design and implement new inventory management systems to reduce inventory costs and improve inventory turnover rate.

- Lead teams of engineers to implement new production lines and processes, resulting in reduced production costs and increased throughput.

- Develop and conduct training programs for employees on lean manufacturing and process improvement techniques.

- Analyze energy consumption data to identify areas for improvement and implement energy efficiency measures, resulting in reduced energy costs.

Frequently Asked Questions (FAQ’s) For Efficiency Engineer

What is the role of an Efficiency Engineer?

An Efficiency Engineer is responsible for analyzing and improving the efficiency of production processes and systems within an organization. They identify and eliminate inefficiencies, implement lean manufacturing principles, and lead continuous improvement initiatives to enhance operational performance.

What skills are required to be an effective Efficiency Engineer?

Effective Efficiency Engineers possess a strong understanding of lean manufacturing principles, data analysis techniques, statistical analysis, and project management. They are also skilled in process improvement, time and motion studies, and energy efficiency measures.

What are the career prospects for Efficiency Engineers?

Efficiency Engineers have excellent career prospects, as businesses continuously seek to improve their operational efficiency. With experience and expertise, they can advance to leadership roles, such as Production Manager, Operations Manager, or even Plant Manager.

What industries employ Efficiency Engineers?

Efficiency Engineers are employed in various industries, including manufacturing, healthcare, logistics, and retail. They play a crucial role in optimizing production processes, reducing waste, and enhancing overall operational efficiency.

What is the average salary for an Efficiency Engineer?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Industrial Engineers, which includes Efficiency Engineers, was $95,300 in May 2021.

What is the job outlook for Efficiency Engineers?

The job outlook for Efficiency Engineers is expected to grow faster than average in the coming years. As businesses continue to focus on improving efficiency and productivity, the demand for skilled Efficiency Engineers is likely to increase.