Are you a seasoned Electric Cutter Operator seeking a new career path? Discover our professionally built Electric Cutter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

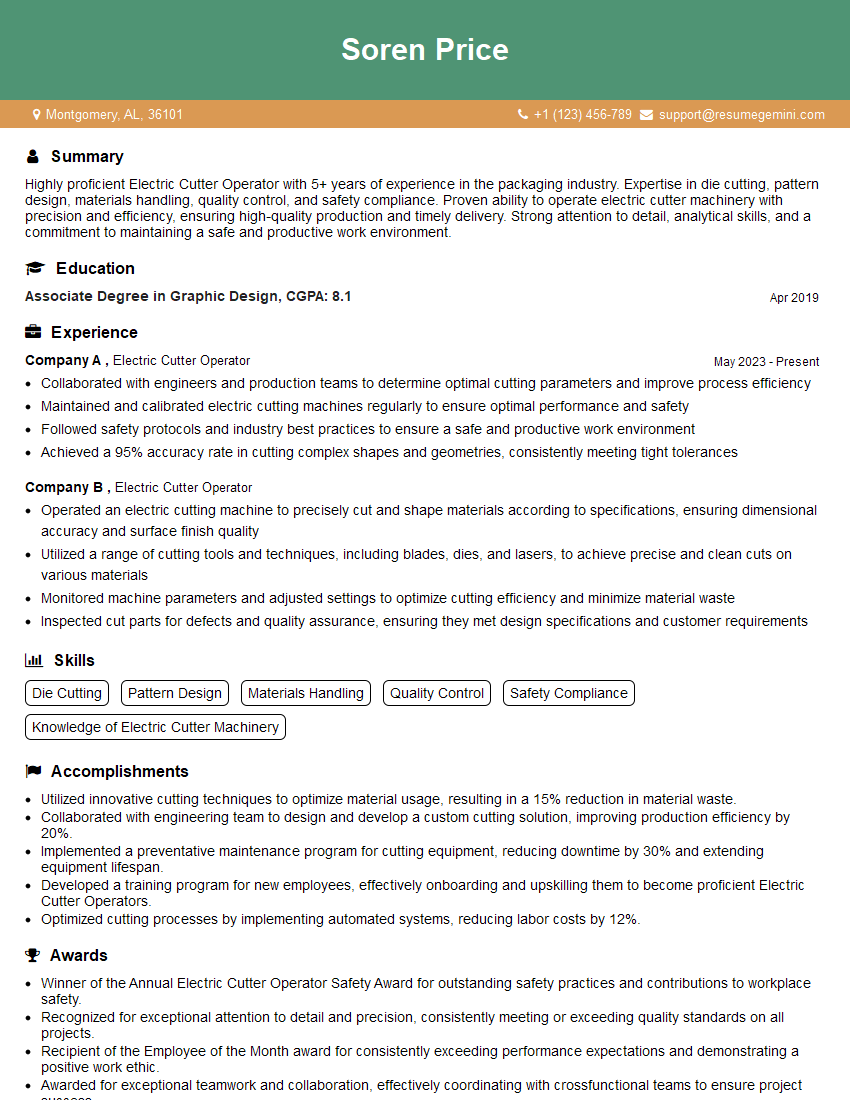

Soren Price

Electric Cutter Operator

Summary

Highly proficient Electric Cutter Operator with 5+ years of experience in the packaging industry. Expertise in die cutting, pattern design, materials handling, quality control, and safety compliance. Proven ability to operate electric cutter machinery with precision and efficiency, ensuring high-quality production and timely delivery. Strong attention to detail, analytical skills, and a commitment to maintaining a safe and productive work environment.

Education

Associate Degree in Graphic Design

April 2019

Skills

- Die Cutting

- Pattern Design

- Materials Handling

- Quality Control

- Safety Compliance

- Knowledge of Electric Cutter Machinery

Work Experience

Electric Cutter Operator

- Collaborated with engineers and production teams to determine optimal cutting parameters and improve process efficiency

- Maintained and calibrated electric cutting machines regularly to ensure optimal performance and safety

- Followed safety protocols and industry best practices to ensure a safe and productive work environment

- Achieved a 95% accuracy rate in cutting complex shapes and geometries, consistently meeting tight tolerances

Electric Cutter Operator

- Operated an electric cutting machine to precisely cut and shape materials according to specifications, ensuring dimensional accuracy and surface finish quality

- Utilized a range of cutting tools and techniques, including blades, dies, and lasers, to achieve precise and clean cuts on various materials

- Monitored machine parameters and adjusted settings to optimize cutting efficiency and minimize material waste

- Inspected cut parts for defects and quality assurance, ensuring they met design specifications and customer requirements

Accomplishments

- Utilized innovative cutting techniques to optimize material usage, resulting in a 15% reduction in material waste.

- Collaborated with engineering team to design and develop a custom cutting solution, improving production efficiency by 20%.

- Implemented a preventative maintenance program for cutting equipment, reducing downtime by 30% and extending equipment lifespan.

- Developed a training program for new employees, effectively onboarding and upskilling them to become proficient Electric Cutter Operators.

- Optimized cutting processes by implementing automated systems, reducing labor costs by 12%.

Awards

- Winner of the Annual Electric Cutter Operator Safety Award for outstanding safety practices and contributions to workplace safety.

- Recognized for exceptional attention to detail and precision, consistently meeting or exceeding quality standards on all projects.

- Recipient of the Employee of the Month award for consistently exceeding performance expectations and demonstrating a positive work ethic.

- Awarded for exceptional teamwork and collaboration, effectively coordinating with crossfunctional teams to ensure project success.

Certificates

- Electric Cutter Operator Certification

- Die Cutting Certification

- Quality Control Certification

- OSHA Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electric Cutter Operator

- Highlight your proficiency in die cutting techniques and your understanding of different materials and their cutting characteristics.

- Showcase your strong attention to detail and ability to produce high-quality work within tight deadlines.

- Emphasize your knowledge of electric cutter machinery and your commitment to safety compliance.

- Include quantifiable results and metrics to demonstrate your contributions to the organization, such as increased production efficiency or reduced waste.

Essential Experience Highlights for a Strong Electric Cutter Operator Resume

- Operate electric cutter machinery to precisely cut and shape various materials, including paper, cardboard, and plastic.

- Analyze and interpret technical drawings and specifications to determine cutting parameters.

- Adjust and calibrate cutter settings to optimize performance and ensure accurate results.

- Monitor the production process and ensure that all cuts meet quality standards.

- Perform routine maintenance and cleaning of equipment to prevent downtime and maintain optimal operating efficiency.

- Adhere to established safety protocols and regulations to minimize risks and promote a safe work environment.

- Collaborate with team members to achieve production goals and resolve any technical issues.

Frequently Asked Questions (FAQ’s) For Electric Cutter Operator

What are the key skills required to be an Electric Cutter Operator?

The key skills required for an Electric Cutter Operator include die cutting, pattern design, materials handling, quality control, safety compliance, and knowledge of electric cutter machinery.

What is the average salary for an Electric Cutter Operator?

The average salary for an Electric Cutter Operator varies depending on experience, location, and industry. According to Salary.com, the average salary for an Electric Cutter Operator in the United States is around $35,000 per year.

What are the career prospects for an Electric Cutter Operator?

Electric Cutter Operators can advance their careers by gaining experience and developing specialized skills. Some may move into supervisory roles, such as Production Supervisor or Quality Control Manager. Others may pursue further education or training to qualify for more technical roles, such as Engineer or Product Designer.

What are the working conditions like for an Electric Cutter Operator?

Electric Cutter Operators typically work in a manufacturing environment. They may work in a factory or production facility, operating electric cutter machinery to cut and shape materials. The work can be physically demanding and may involve working with sharp objects. It is important for Electric Cutter Operators to follow safety protocols and wear appropriate protective gear.

What are the educational requirements for an Electric Cutter Operator?

While formal education requirements may vary depending on the specific job, many employers prefer candidates with an associate degree in a related field, such as graphic design or manufacturing technology. Some employers may also provide on-the-job training for qualified candidates.

What are the benefits of working as an Electric Cutter Operator?

Working as an Electric Cutter Operator can offer several benefits, including job stability, opportunities for advancement, and a competitive salary. Electric Cutter Operators play a vital role in the manufacturing process and are in high demand in various industries.

What are the challenges of working as an Electric Cutter Operator?

The challenges of working as an Electric Cutter Operator can include working with sharp objects, exposure to noise and dust, and physically demanding tasks. It is important for Electric Cutter Operators to follow safety protocols and take necessary precautions to minimize risks and maintain a safe work environment.