Are you a seasoned Electronic Die Maker seeking a new career path? Discover our professionally built Electronic Die Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

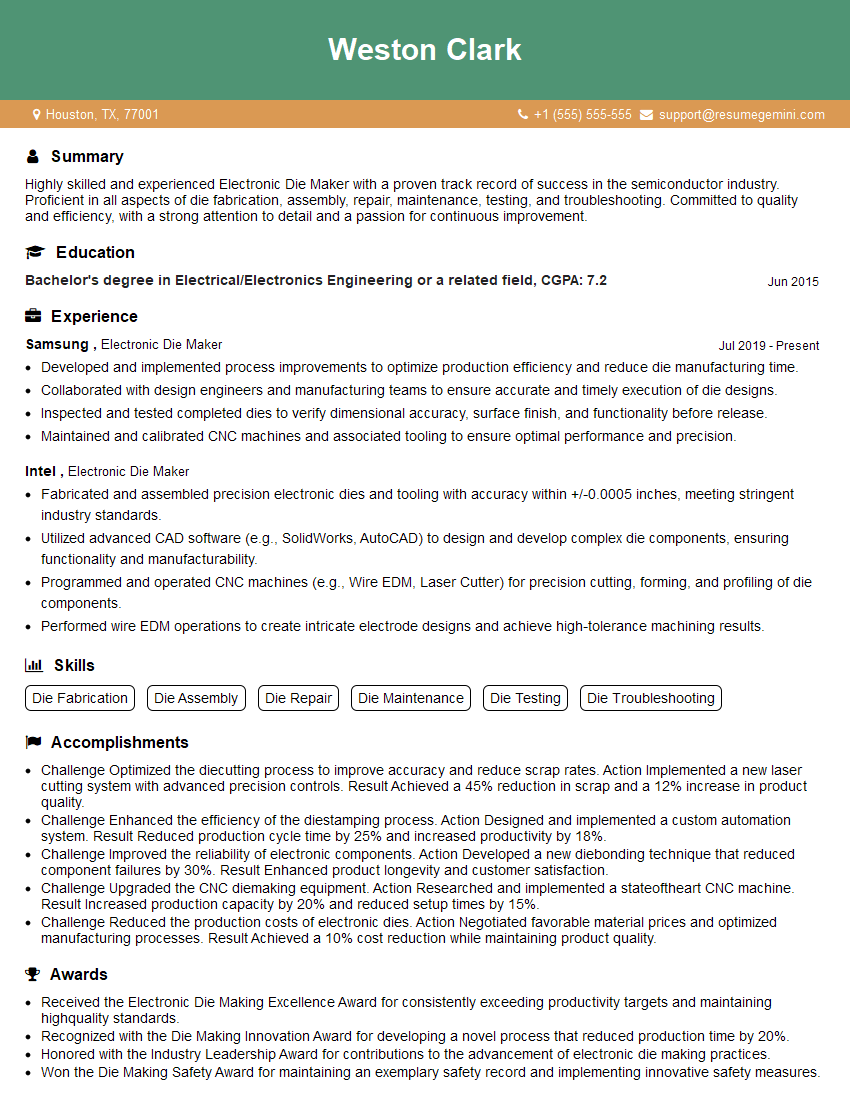

Weston Clark

Electronic Die Maker

Summary

Highly skilled and experienced Electronic Die Maker with a proven track record of success in the semiconductor industry. Proficient in all aspects of die fabrication, assembly, repair, maintenance, testing, and troubleshooting. Committed to quality and efficiency, with a strong attention to detail and a passion for continuous improvement.

Education

Bachelor’s degree in Electrical/Electronics Engineering or a related field

June 2015

Skills

- Die Fabrication

- Die Assembly

- Die Repair

- Die Maintenance

- Die Testing

- Die Troubleshooting

Work Experience

Electronic Die Maker

- Developed and implemented process improvements to optimize production efficiency and reduce die manufacturing time.

- Collaborated with design engineers and manufacturing teams to ensure accurate and timely execution of die designs.

- Inspected and tested completed dies to verify dimensional accuracy, surface finish, and functionality before release.

- Maintained and calibrated CNC machines and associated tooling to ensure optimal performance and precision.

Electronic Die Maker

- Fabricated and assembled precision electronic dies and tooling with accuracy within +/-0.0005 inches, meeting stringent industry standards.

- Utilized advanced CAD software (e.g., SolidWorks, AutoCAD) to design and develop complex die components, ensuring functionality and manufacturability.

- Programmed and operated CNC machines (e.g., Wire EDM, Laser Cutter) for precision cutting, forming, and profiling of die components.

- Performed wire EDM operations to create intricate electrode designs and achieve high-tolerance machining results.

Accomplishments

- Challenge Optimized the diecutting process to improve accuracy and reduce scrap rates. Action Implemented a new laser cutting system with advanced precision controls. Result Achieved a 45% reduction in scrap and a 12% increase in product quality.

- Challenge Enhanced the efficiency of the diestamping process. Action Designed and implemented a custom automation system. Result Reduced production cycle time by 25% and increased productivity by 18%.

- Challenge Improved the reliability of electronic components. Action Developed a new diebonding technique that reduced component failures by 30%. Result Enhanced product longevity and customer satisfaction.

- Challenge Upgraded the CNC diemaking equipment. Action Researched and implemented a stateoftheart CNC machine. Result Increased production capacity by 20% and reduced setup times by 15%.

- Challenge Reduced the production costs of electronic dies. Action Negotiated favorable material prices and optimized manufacturing processes. Result Achieved a 10% cost reduction while maintaining product quality.

Awards

- Received the Electronic Die Making Excellence Award for consistently exceeding productivity targets and maintaining highquality standards.

- Recognized with the Die Making Innovation Award for developing a novel process that reduced production time by 20%.

- Honored with the Industry Leadership Award for contributions to the advancement of electronic die making practices.

- Won the Die Making Safety Award for maintaining an exemplary safety record and implementing innovative safety measures.

Certificates

- Certified Die Maker (CDM)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Plant Maintenance Manager (CPMM)

- Certified Maintenance Planner and Scheduler (CMPS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electronic Die Maker

- Highlight your technical skills and experience in die fabrication and assembly.

- Quantify your accomplishments whenever possible to demonstrate your impact.

- Proofread your resume carefully for any errors.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Electronic Die Maker Resume

- Fabricate and assemble electronic dies according to specifications

- Repair and maintain dies to ensure optimal performance

- Troubleshoot and resolve die-related issues

- Conduct quality control inspections and testing

- Develop and implement process improvements to enhance efficiency

- Follow safety protocols and maintain a clean and organized work environment

- Collaborate with engineers and other team members to ensure project success

Frequently Asked Questions (FAQ’s) For Electronic Die Maker

What is the role of an Electronic Die Maker?

An Electronic Die Maker is responsible for the fabrication, assembly, repair, maintenance, testing, and troubleshooting of electronic dies. They work in a cleanroom environment, using specialized equipment and materials to create and maintain these essential components of electronic devices.

What are the key skills required to be an Electronic Die Maker?

The key skills required to be an Electronic Die Maker include die fabrication, die assembly, die repair, die maintenance, die testing, and die troubleshooting. They must also have a strong understanding of electrical and electronic principles, as well as the ability to work in a cleanroom environment.

What is the job outlook for Electronic Die Makers?

The job outlook for Electronic Die Makers is expected to be good over the next few years, as the demand for electronic devices continues to grow. The increasing use of electronics in various industries, such as automotive, healthcare, and consumer electronics, is driving the demand for skilled Electronic Die Makers.

What is the average salary for an Electronic Die Maker?

The average salary for an Electronic Die Maker in the United States is around $60,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the career advancement opportunities for Electronic Die Makers?

Electronic Die Makers can advance their careers by taking on more responsibility, such as becoming a lead or supervisor. They can also specialize in a particular area, such as die design or die testing. With additional education and experience, Electronic Die Makers can also move into management or engineering roles.

What are the challenges of being an Electronic Die Maker?

The challenges of being an Electronic Die Maker include working in a cleanroom environment, which can be restrictive and uncomfortable. The work can also be repetitive and requires a high level of precision and attention to detail. Additionally, Electronic Die Makers may be exposed to hazardous chemicals and materials.

What is the work environment for an Electronic Die Maker?

Electronic Die Makers typically work in a cleanroom environment, which is a controlled environment with strict temperature, humidity, and cleanliness standards. They may also work in a laboratory or production setting.

What are the benefits of being an Electronic Die Maker?

The benefits of being an Electronic Die Maker include job security, as the demand for these professionals is expected to continue to grow. They also have the opportunity to work with cutting-edge technology and contribute to the development of new electronic devices.