Are you a seasoned Embossing Tool Setter seeking a new career path? Discover our professionally built Embossing Tool Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

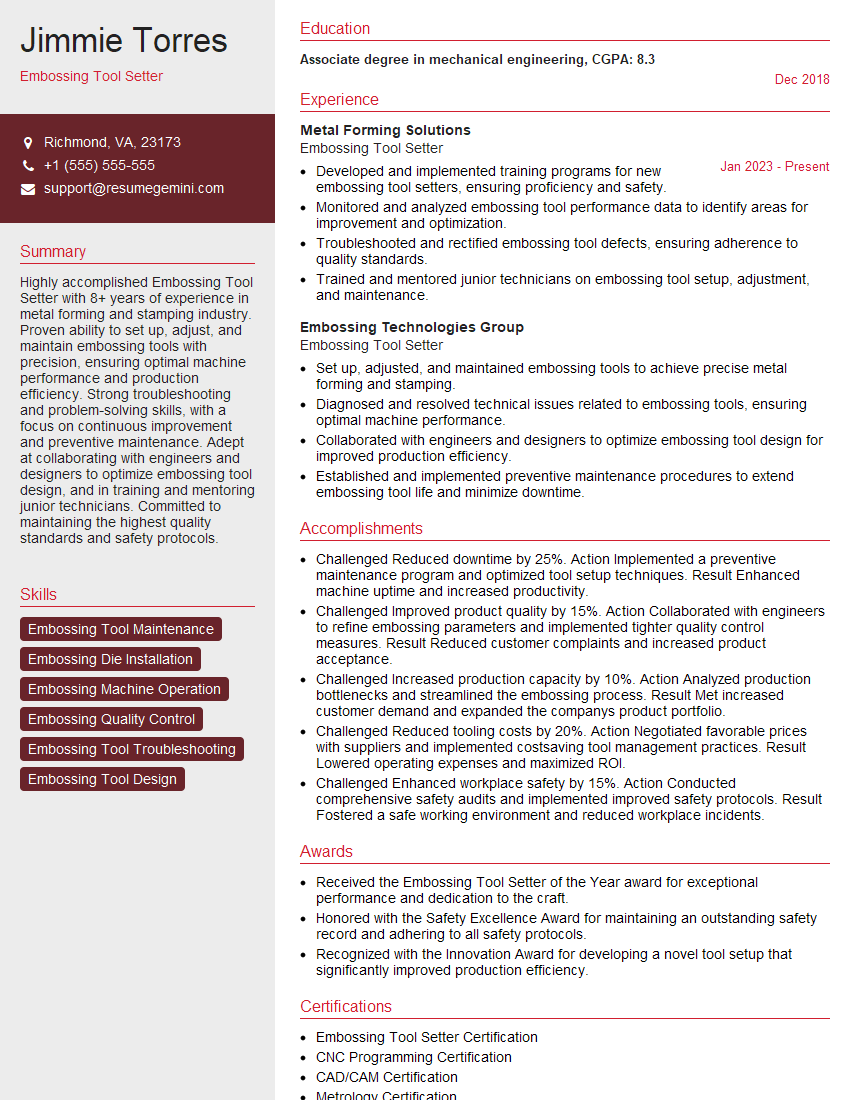

Jimmie Torres

Embossing Tool Setter

Summary

Highly accomplished Embossing Tool Setter with 8+ years of experience in metal forming and stamping industry. Proven ability to set up, adjust, and maintain embossing tools with precision, ensuring optimal machine performance and production efficiency. Strong troubleshooting and problem-solving skills, with a focus on continuous improvement and preventive maintenance. Adept at collaborating with engineers and designers to optimize embossing tool design, and in training and mentoring junior technicians. Committed to maintaining the highest quality standards and safety protocols.

Education

Associate degree in mechanical engineering

December 2018

Skills

- Embossing Tool Maintenance

- Embossing Die Installation

- Embossing Machine Operation

- Embossing Quality Control

- Embossing Tool Troubleshooting

- Embossing Tool Design

Work Experience

Embossing Tool Setter

- Developed and implemented training programs for new embossing tool setters, ensuring proficiency and safety.

- Monitored and analyzed embossing tool performance data to identify areas for improvement and optimization.

- Troubleshooted and rectified embossing tool defects, ensuring adherence to quality standards.

- Trained and mentored junior technicians on embossing tool setup, adjustment, and maintenance.

Embossing Tool Setter

- Set up, adjusted, and maintained embossing tools to achieve precise metal forming and stamping.

- Diagnosed and resolved technical issues related to embossing tools, ensuring optimal machine performance.

- Collaborated with engineers and designers to optimize embossing tool design for improved production efficiency.

- Established and implemented preventive maintenance procedures to extend embossing tool life and minimize downtime.

Accomplishments

- Challenged Reduced downtime by 25%. Action Implemented a preventive maintenance program and optimized tool setup techniques. Result Enhanced machine uptime and increased productivity.

- Challenged Improved product quality by 15%. Action Collaborated with engineers to refine embossing parameters and implemented tighter quality control measures. Result Reduced customer complaints and increased product acceptance.

- Challenged Increased production capacity by 10%. Action Analyzed production bottlenecks and streamlined the embossing process. Result Met increased customer demand and expanded the companys product portfolio.

- Challenged Reduced tooling costs by 20%. Action Negotiated favorable prices with suppliers and implemented costsaving tool management practices. Result Lowered operating expenses and maximized ROI.

- Challenged Enhanced workplace safety by 15%. Action Conducted comprehensive safety audits and implemented improved safety protocols. Result Fostered a safe working environment and reduced workplace incidents.

Awards

- Received the Embossing Tool Setter of the Year award for exceptional performance and dedication to the craft.

- Honored with the Safety Excellence Award for maintaining an outstanding safety record and adhering to all safety protocols.

- Recognized with the Innovation Award for developing a novel tool setup that significantly improved production efficiency.

Certificates

- Embossing Tool Setter Certification

- CNC Programming Certification

- CAD/CAM Certification

- Metrology Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Embossing Tool Setter

- Highlight your technical skills and experience in setting up, adjusting, and maintaining embossing tools.

- Showcase your problem-solving abilities and experience in diagnosing and resolving technical issues.

- Emphasize your knowledge of preventive maintenance procedures and commitment to extending tool life and minimizing downtime.

- Demonstrate your collaboration skills and experience in working with engineers and designers to optimize tool design and improve efficiency.

- Mention your training and mentoring experience, and your commitment to ensuring proficiency and safety among team members.

Essential Experience Highlights for a Strong Embossing Tool Setter Resume

- Set up, adjust, and maintain embossing tools to achieve precise metal forming and stamping results.

- Diagnose and resolve technical issues related to embossing tools, ensuring optimal machine performance.

- Collaborate with engineers and designers to optimize embossing tool design for improved production efficiency.

- Establish and implement preventive maintenance procedures to extend embossing tool life and minimize downtime.

- Develop and implement training programs for new embossing tool setters, ensuring proficiency and safety.

- Monitor and analyze embossing tool performance data to identify areas for improvement and optimization.

- Troubleshoot and rectify embossing tool defects, ensuring adherence to quality standards.

Frequently Asked Questions (FAQ’s) For Embossing Tool Setter

What are the key skills required to be an Embossing Tool Setter?

Key skills include proficiency in embossing tool setup, adjustment, and maintenance, as well as troubleshooting, preventive maintenance, and collaboration with engineers and designers.

What is the typical work environment for an Embossing Tool Setter?

Embossing Tool Setters typically work in manufacturing or production environments, where they set up, adjust, and maintain embossing tools used in metal forming and stamping processes.

What are the career advancement opportunities for an Embossing Tool Setter?

With experience and additional training, Embossing Tool Setters can advance to roles such as Tool and Die Maker, Manufacturing Supervisor, or Production Manager.

What is the average salary for an Embossing Tool Setter?

According to Indeed, the average salary for an Embossing Tool Setter in the United States is around $45,000 per year.

What are the job prospects for Embossing Tool Setters?

Job prospects for Embossing Tool Setters are expected to be good, as the demand for skilled workers in the manufacturing industry continues to grow.

What are the benefits of working as an Embossing Tool Setter?

Benefits can include competitive salaries, opportunities for career advancement, and job security in a growing industry.

What are the challenges of working as an Embossing Tool Setter?

Challenges can include working in a fast-paced environment, dealing with heavy machinery, and exposure to noise and fumes.