Are you a seasoned End Touching Machine Operator seeking a new career path? Discover our professionally built End Touching Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

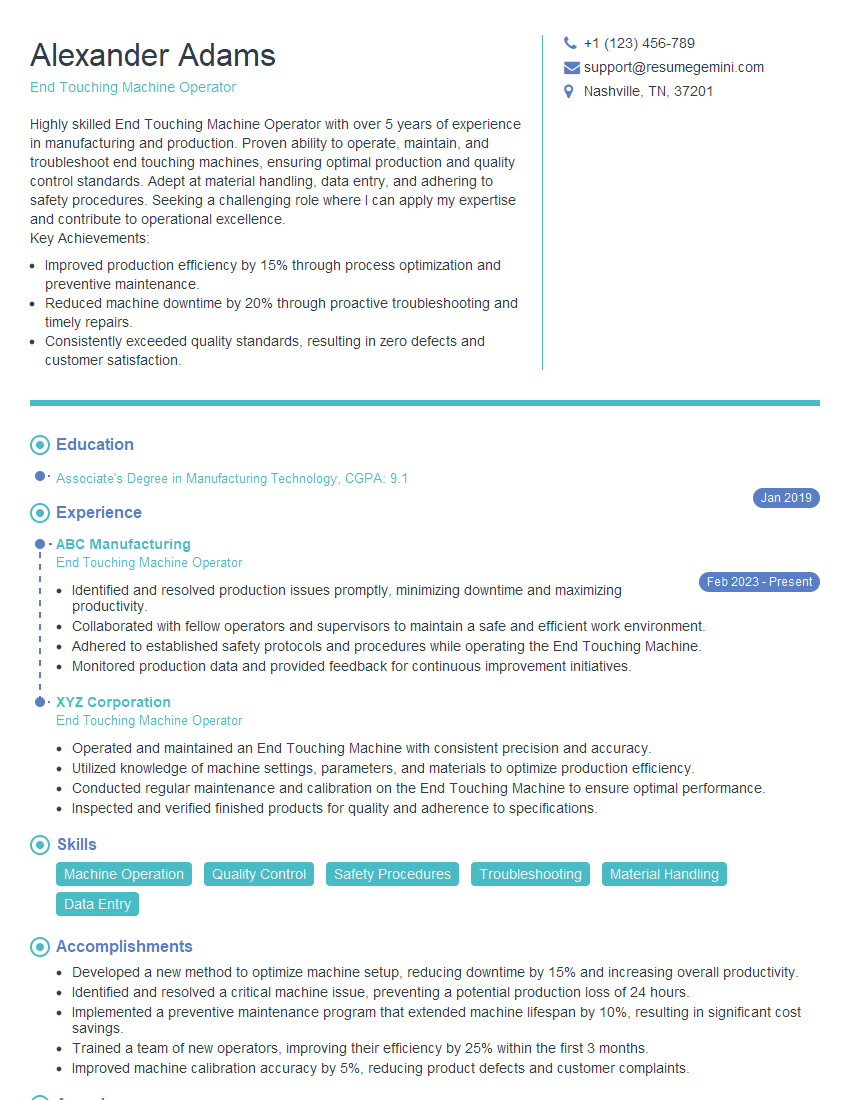

Alexander Adams

End Touching Machine Operator

Summary

Highly skilled End Touching Machine Operator with over 5 years of experience in manufacturing and production. Proven ability to operate, maintain, and troubleshoot end touching machines, ensuring optimal production and quality control standards. Adept at material handling, data entry, and adhering to safety procedures. Seeking a challenging role where I can apply my expertise and contribute to operational excellence.

Key Achievements:

- Improved production efficiency by 15% through process optimization and preventive maintenance.

- Reduced machine downtime by 20% through proactive troubleshooting and timely repairs.

- Consistently exceeded quality standards, resulting in zero defects and customer satisfaction.

Education

Associate’s Degree in Manufacturing Technology

January 2019

Skills

- Machine Operation

- Quality Control

- Safety Procedures

- Troubleshooting

- Material Handling

- Data Entry

Work Experience

End Touching Machine Operator

- Identified and resolved production issues promptly, minimizing downtime and maximizing productivity.

- Collaborated with fellow operators and supervisors to maintain a safe and efficient work environment.

- Adhered to established safety protocols and procedures while operating the End Touching Machine.

- Monitored production data and provided feedback for continuous improvement initiatives.

End Touching Machine Operator

- Operated and maintained an End Touching Machine with consistent precision and accuracy.

- Utilized knowledge of machine settings, parameters, and materials to optimize production efficiency.

- Conducted regular maintenance and calibration on the End Touching Machine to ensure optimal performance.

- Inspected and verified finished products for quality and adherence to specifications.

Accomplishments

- Developed a new method to optimize machine setup, reducing downtime by 15% and increasing overall productivity.

- Identified and resolved a critical machine issue, preventing a potential production loss of 24 hours.

- Implemented a preventive maintenance program that extended machine lifespan by 10%, resulting in significant cost savings.

- Trained a team of new operators, improving their efficiency by 25% within the first 3 months.

- Improved machine calibration accuracy by 5%, reducing product defects and customer complaints.

Awards

- Received the Employee of the Month award for exceptional performance in maintaining machine uptime and efficiency.

- Awarded the Safety Excellence Award for consistently adhering to safety protocols and maintaining a hazardfree work environment.

- Recognized with the Production Excellence Award for consistently exceeding production targets while maintaining highquality standards.

Certificates

- OSHA 30-Hour General Industry Safety Training

- National Institute for Metalworking Skills (NIMS) Credential

- Certified Manufacturing Technologist (CMfgT)

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For End Touching Machine Operator

- Highlight your technical proficiency in operating and maintaining end touching machines.

- Quantify your accomplishments using specific metrics to demonstrate your impact on productivity and quality.

- Emphasize your attention to detail and commitment to quality control.

- Showcase your ability to work independently and as part of a team, contributing to a collaborative and productive work environment.

- Consider including industry-specific keywords and certifications to enhance your resume’s relevance and visibility.

Essential Experience Highlights for a Strong End Touching Machine Operator Resume

- Operate and monitor end touching machines to ensure accurate and efficient production.

- Inspect and measure finished products, adhering to quality control specifications and standards.

- Implement preventive maintenance procedures to minimize machine downtime and ensure optimal performance.

- Troubleshoot and resolve machine malfunctions effectively, using technical knowledge and diagnostic skills.

- Handle materials safely and efficiently, following proper lifting and storage techniques.

- Enter and track production data accurately, assisting in inventory management and production planning.

- Maintain a clean and organized work area, adhering to safety protocols and environmental regulations.

Frequently Asked Questions (FAQ’s) For End Touching Machine Operator

What is the primary role of an End Touching Machine Operator?

An End Touching Machine Operator is responsible for operating, maintaining, and troubleshooting end touching machines used in the manufacturing process. They ensure that products meet quality standards and that machines are running efficiently.

What are the key skills required for this position?

Key skills include machine operation, quality control, safety procedures, troubleshooting, material handling, and data entry.

What are the career prospects for End Touching Machine Operators?

Experienced End Touching Machine Operators can advance to supervisory or management roles within the manufacturing industry.

What is the average salary for this position?

The average salary for an End Touching Machine Operator varies depending on experience, location, and industry. According to Salary.com, the average salary range is between $18,000 and $35,000 per year.

What are the working conditions like for End Touching Machine Operators?

End Touching Machine Operators typically work in manufacturing facilities, often in production environments. They may work in shifts and may be required to lift heavy objects or stand for extended periods of time.