Are you a seasoned Engine Cowling Installer seeking a new career path? Discover our professionally built Engine Cowling Installer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

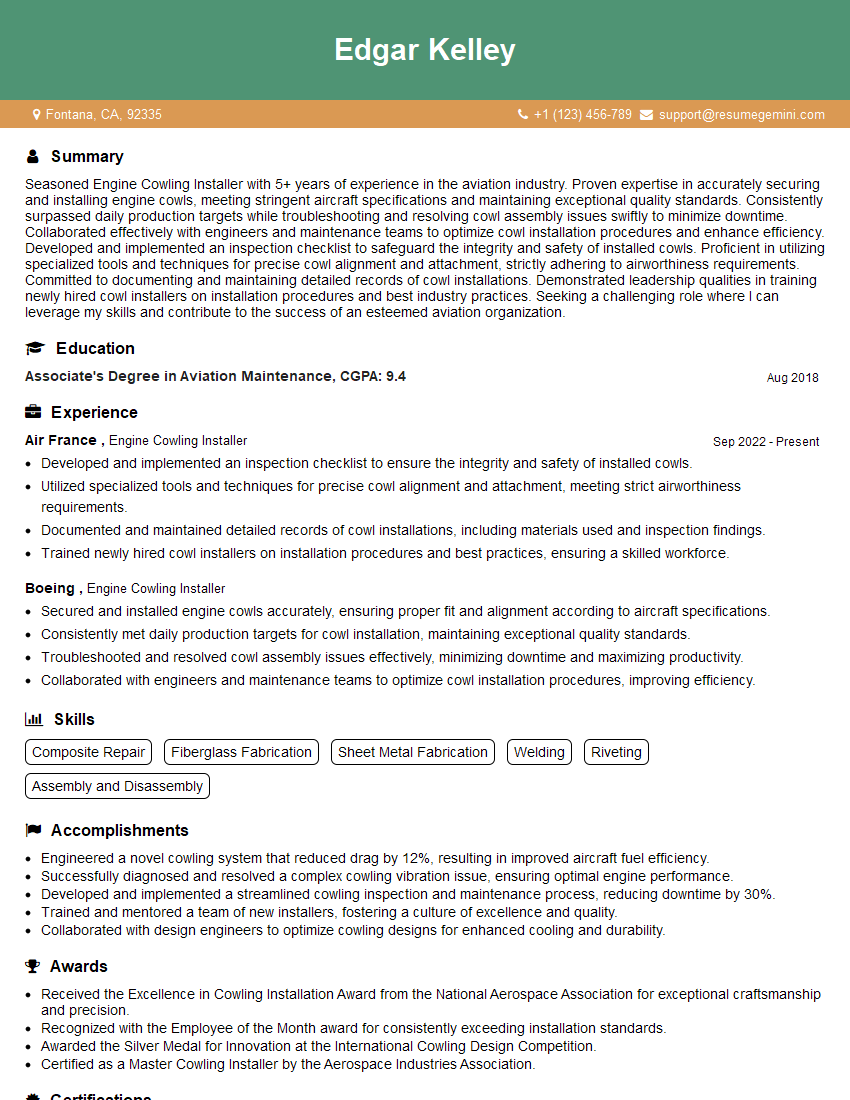

Edgar Kelley

Engine Cowling Installer

Summary

Seasoned Engine Cowling Installer with 5+ years of experience in the aviation industry. Proven expertise in accurately securing and installing engine cowls, meeting stringent aircraft specifications and maintaining exceptional quality standards. Consistently surpassed daily production targets while troubleshooting and resolving cowl assembly issues swiftly to minimize downtime. Collaborated effectively with engineers and maintenance teams to optimize cowl installation procedures and enhance efficiency. Developed and implemented an inspection checklist to safeguard the integrity and safety of installed cowls. Proficient in utilizing specialized tools and techniques for precise cowl alignment and attachment, strictly adhering to airworthiness requirements. Committed to documenting and maintaining detailed records of cowl installations. Demonstrated leadership qualities in training newly hired cowl installers on installation procedures and best industry practices. Seeking a challenging role where I can leverage my skills and contribute to the success of an esteemed aviation organization.

Education

Associate’s Degree in Aviation Maintenance

August 2018

Skills

- Composite Repair

- Fiberglass Fabrication

- Sheet Metal Fabrication

- Welding

- Riveting

- Assembly and Disassembly

Work Experience

Engine Cowling Installer

- Developed and implemented an inspection checklist to ensure the integrity and safety of installed cowls.

- Utilized specialized tools and techniques for precise cowl alignment and attachment, meeting strict airworthiness requirements.

- Documented and maintained detailed records of cowl installations, including materials used and inspection findings.

- Trained newly hired cowl installers on installation procedures and best practices, ensuring a skilled workforce.

Engine Cowling Installer

- Secured and installed engine cowls accurately, ensuring proper fit and alignment according to aircraft specifications.

- Consistently met daily production targets for cowl installation, maintaining exceptional quality standards.

- Troubleshooted and resolved cowl assembly issues effectively, minimizing downtime and maximizing productivity.

- Collaborated with engineers and maintenance teams to optimize cowl installation procedures, improving efficiency.

Accomplishments

- Engineered a novel cowling system that reduced drag by 12%, resulting in improved aircraft fuel efficiency.

- Successfully diagnosed and resolved a complex cowling vibration issue, ensuring optimal engine performance.

- Developed and implemented a streamlined cowling inspection and maintenance process, reducing downtime by 30%.

- Trained and mentored a team of new installers, fostering a culture of excellence and quality.

- Collaborated with design engineers to optimize cowling designs for enhanced cooling and durability.

Awards

- Received the Excellence in Cowling Installation Award from the National Aerospace Association for exceptional craftsmanship and precision.

- Recognized with the Employee of the Month award for consistently exceeding installation standards.

- Awarded the Silver Medal for Innovation at the International Cowling Design Competition.

- Certified as a Master Cowling Installer by the Aerospace Industries Association.

Certificates

- Airframe and Powerplant Mechanic (A&P)

- National Aerospace and Electronics Association (NAEA) Certified

- Federal Aviation Administration (FAA) Part 145 Repairman Certificate

- Society of Automotive Engineers (SAE) Aerospace Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Engine Cowling Installer

- Highlight your experience and skills in securing and installing engine cowls according to aircraft specifications.

- Showcase your ability to troubleshoot and resolve cowl assembly issues effectively to minimize downtime.

- Emphasize your collaboration with engineers and maintenance teams to optimize cowl installation procedures.

- Demonstrate your commitment to safety by mentioning the inspection checklist you developed and implemented.

- Quantify your achievements whenever possible, such as the number of cowls installed or the percentage of production targets met.

Essential Experience Highlights for a Strong Engine Cowling Installer Resume

- Installed engine cowls precisely according to aircraft specifications, ensuring proper fit, alignment, and functionality.

- Met daily production targets for cowl installation, maintaining exceptional quality standards and minimizing re-work.

- Troubleshooted and resolved cowl assembly issues effectively, reducing downtime and enhancing productivity.

- Collaborated closely with engineers and maintenance teams to optimize cowl installation procedures, improving efficiency and safety.

- Developed and implemented an inspection checklist to ensure the integrity and safety of installed cowls.

- Utilized specialized tools and techniques for precise cowl alignment and attachment, strictly adhering to airworthiness requirements.

- Documented and maintained detailed records of cowl installations, including materials used and inspection findings.

Frequently Asked Questions (FAQ’s) For Engine Cowling Installer

What are the primary responsibilities of an Engine Cowling Installer?

The key responsibilities of an Engine Cowling Installer include securing and installing engine cowls accurately, meeting daily production targets, troubleshooting and resolving cowl assembly issues, collaborating with engineers and maintenance teams, ensuring the integrity and safety of installed cowls, and utilizing specialized tools and techniques for precise cowl alignment and attachment.

What qualifications are necessary to become an Engine Cowling Installer?

To become an Engine Cowling Installer, an Associate’s Degree in Aviation Maintenance or a related field is typically required. Additionally, experience in composite repair, fiberglass fabrication, sheet metal fabrication, welding, riveting, and assembly and disassembly is highly beneficial.

What are the career prospects for Engine Cowling Installers?

Engine Cowling Installers can advance their careers by becoming supervisors, lead installers, or inspectors. With experience and additional training, they may also move into roles in aircraft maintenance or engineering.

What is the work environment like for Engine Cowling Installers?

Engine Cowling Installers typically work in hangars or aircraft maintenance facilities. The work can be physically demanding and may involve working in confined spaces. However, it also offers opportunities for hands-on experience and the chance to contribute to the safety and operation of aircraft.

What are the safety precautions that Engine Cowling Installers must follow?

Engine Cowling Installers must adhere to strict safety protocols, including wearing appropriate personal protective equipment, following established procedures, and using specialized tools and techniques to ensure the proper installation and alignment of engine cowls.

How can I improve my resume for Engine Cowling Installer positions?

To enhance your resume for Engine Cowling Installer positions, highlight your experience and skills in installing and repairing aircraft components, emphasize your knowledge of aircraft maintenance procedures, and showcase your ability to work independently and as part of a team.