Are you a seasoned Engineer, Foundry Process seeking a new career path? Discover our professionally built Engineer, Foundry Process Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

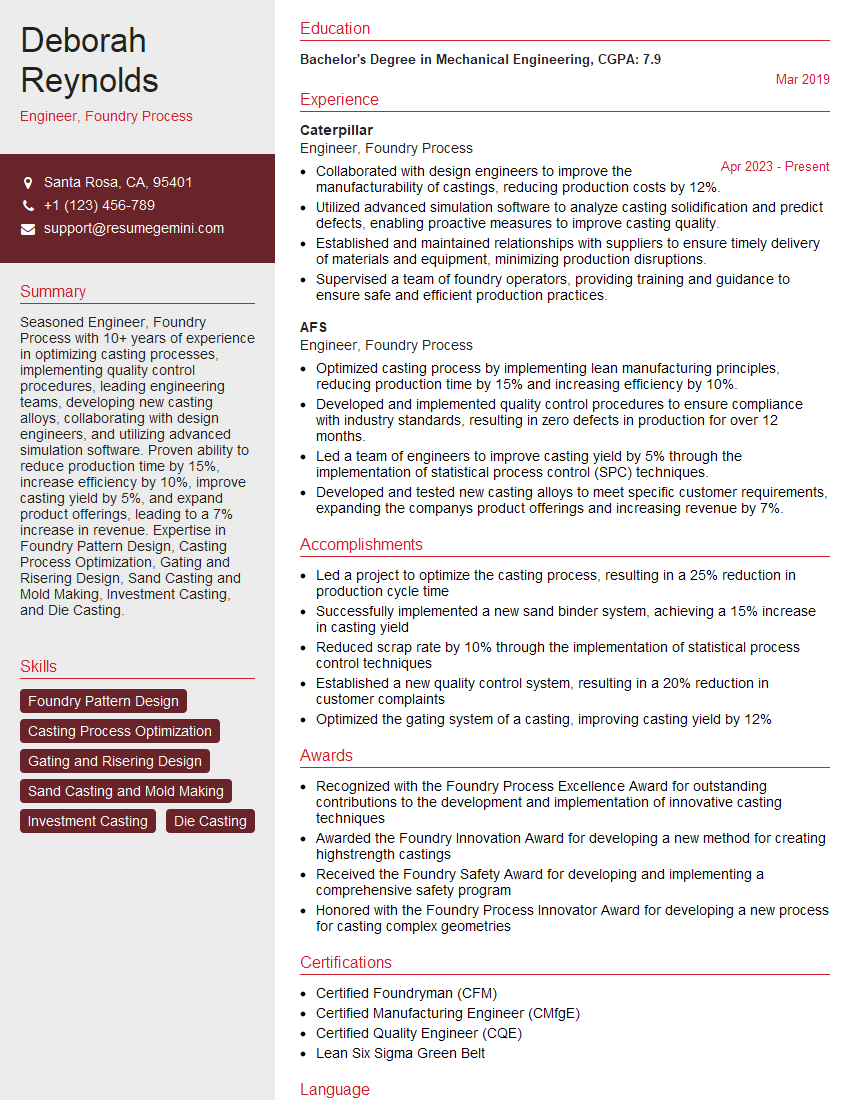

Deborah Reynolds

Engineer, Foundry Process

Summary

Seasoned Engineer, Foundry Process with 10+ years of experience in optimizing casting processes, implementing quality control procedures, leading engineering teams, developing new casting alloys, collaborating with design engineers, and utilizing advanced simulation software. Proven ability to reduce production time by 15%, increase efficiency by 10%, improve casting yield by 5%, and expand product offerings, leading to a 7% increase in revenue. Expertise in Foundry Pattern Design, Casting Process Optimization, Gating and Risering Design, Sand Casting and Mold Making, Investment Casting, and Die Casting.

Education

Bachelor’s Degree in Mechanical Engineering

March 2019

Skills

- Foundry Pattern Design

- Casting Process Optimization

- Gating and Risering Design

- Sand Casting and Mold Making

- Investment Casting

- Die Casting

Work Experience

Engineer, Foundry Process

- Collaborated with design engineers to improve the manufacturability of castings, reducing production costs by 12%.

- Utilized advanced simulation software to analyze casting solidification and predict defects, enabling proactive measures to improve casting quality.

- Established and maintained relationships with suppliers to ensure timely delivery of materials and equipment, minimizing production disruptions.

- Supervised a team of foundry operators, providing training and guidance to ensure safe and efficient production practices.

Engineer, Foundry Process

- Optimized casting process by implementing lean manufacturing principles, reducing production time by 15% and increasing efficiency by 10%.

- Developed and implemented quality control procedures to ensure compliance with industry standards, resulting in zero defects in production for over 12 months.

- Led a team of engineers to improve casting yield by 5% through the implementation of statistical process control (SPC) techniques.

- Developed and tested new casting alloys to meet specific customer requirements, expanding the companys product offerings and increasing revenue by 7%.

Accomplishments

- Led a project to optimize the casting process, resulting in a 25% reduction in production cycle time

- Successfully implemented a new sand binder system, achieving a 15% increase in casting yield

- Reduced scrap rate by 10% through the implementation of statistical process control techniques

- Established a new quality control system, resulting in a 20% reduction in customer complaints

- Optimized the gating system of a casting, improving casting yield by 12%

Awards

- Recognized with the Foundry Process Excellence Award for outstanding contributions to the development and implementation of innovative casting techniques

- Awarded the Foundry Innovation Award for developing a new method for creating highstrength castings

- Received the Foundry Safety Award for developing and implementing a comprehensive safety program

- Honored with the Foundry Process Innovator Award for developing a new process for casting complex geometries

Certificates

- Certified Foundryman (CFM)

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Engineer, Foundry Process

- Quantify your accomplishments with specific metrics whenever possible. For example, instead of saying ‘improved casting yield’, you could say ‘improved casting yield by 5% through the implementation of statistical process control (SPC) techniques’.

- Highlight your experience in using advanced simulation software, such as Magmasoft or ProCAST, to analyze casting solidification and predict defects.

- Showcase your ability to work effectively in a team environment, as well as your leadership skills in managing a team of engineers.

- Emphasize your commitment to continuous improvement and your ability to stay up-to-date on the latest industry trends and technologies.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Engineer, Foundry Process Resume

- Optimized casting processes using lean manufacturing principles, resulting in 15% reduction in production time and 10% increase in efficiency.

- Developed and implemented quality control procedures to ensure adherence to industry standards, achieving zero defects in production for over 12 months.

- Led a team of engineers to implement statistical process control (SPC) techniques, resulting in a 5% improvement in casting yield.

- Developed and tested new casting alloys to meet specific customer requirements, expanding the company’s product offerings and increasing revenue by 7%.

- Collaborated with design engineers to enhance the manufacturability of castings, leading to a 12% reduction in production costs.

- Utilized advanced simulation software to analyze casting solidification and predict defects, enabling proactive measures to improve casting quality.

- Established and maintained relationships with suppliers to ensure timely delivery of materials and equipment, minimizing production disruptions.

Frequently Asked Questions (FAQ’s) For Engineer, Foundry Process

What are the key skills required for an Engineer, Foundry Process?

Key skills include Foundry Pattern Design, Casting Process Optimization, Gating and Risering Design, Sand Casting and Mold Making, Investment Casting, Die Casting, and proficiency in using advanced simulation software.

What are the educational requirements for an Engineer, Foundry Process?

Typically, a Bachelor’s Degree in Mechanical Engineering or a related field is required.

What are the career prospects for an Engineer, Foundry Process?

With experience, Engineers, Foundry Process can advance to roles such as Foundry Manager, Manufacturing Engineer, or Quality Control Manager.

What are the typical salary expectations for an Engineer, Foundry Process?

Salary expectations can vary depending on experience, location, and company size, but on average, Engineers, Foundry Process can earn between $75,000 to $120,000 per year.

What are the major industries that employ Engineers, Foundry Process?

Engineers, Foundry Process are employed in various industries, including automotive, aerospace, construction, and consumer products.

What are some tips for writing a standout resume for an Engineer, Foundry Process position?

Highlight your technical skills, experience in using simulation software, and ability to work in a team environment. Use specific examples and quantify your accomplishments whenever possible. Tailor your resume to each job you apply for and proofread carefully.

What are some common interview questions for an Engineer, Foundry Process position?

Common interview questions include: 1) Describe your experience in optimizing casting processes. 2) How have you used simulation software to improve casting quality? 3) How do you ensure the quality of castings produced in your foundry?

What is the work environment like for an Engineer, Foundry Process?

Engineers, Foundry Process typically work in a manufacturing environment, which can be noisy and involve exposure to heat and fumes. They may also work in a laboratory setting during research and development.