Are you a seasoned Engineering Production Liaison seeking a new career path? Discover our professionally built Engineering Production Liaison Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

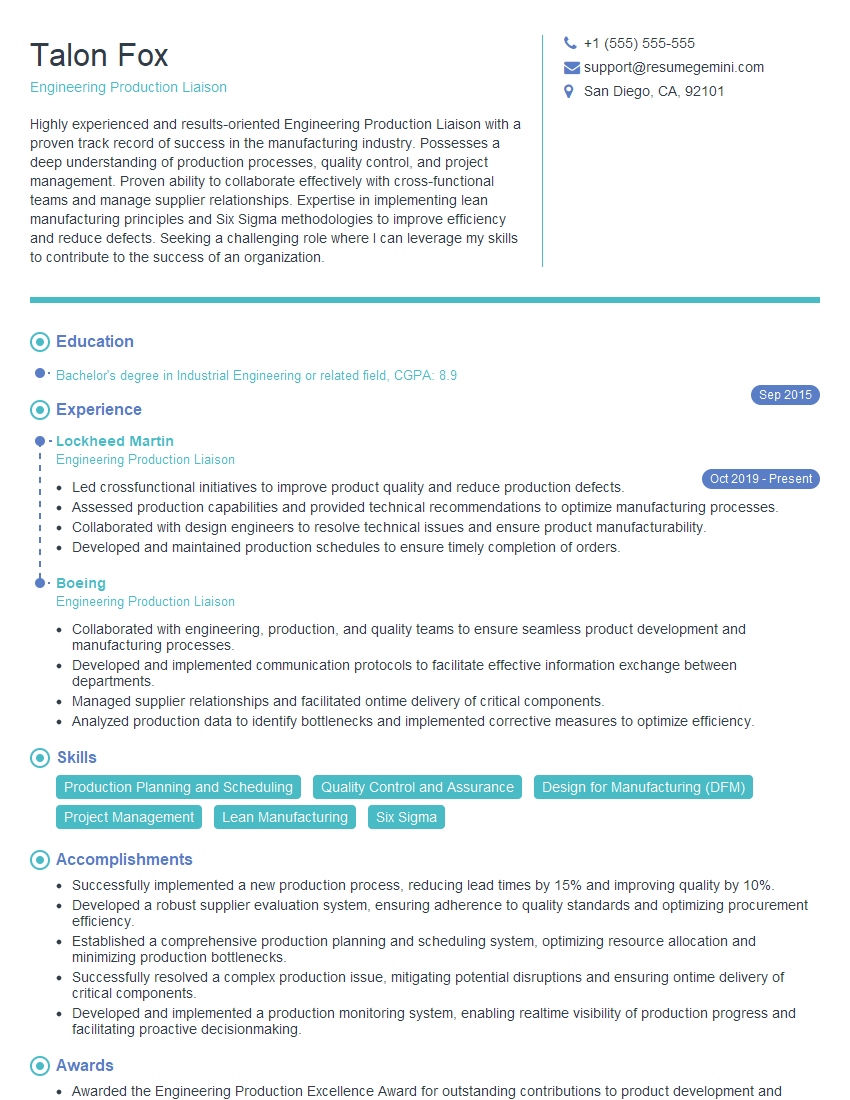

Talon Fox

Engineering Production Liaison

Summary

Highly experienced and results-oriented Engineering Production Liaison with a proven track record of success in the manufacturing industry. Possesses a deep understanding of production processes, quality control, and project management. Proven ability to collaborate effectively with cross-functional teams and manage supplier relationships. Expertise in implementing lean manufacturing principles and Six Sigma methodologies to improve efficiency and reduce defects. Seeking a challenging role where I can leverage my skills to contribute to the success of an organization.

Education

Bachelor’s degree in Industrial Engineering or related field

September 2015

Skills

- Production Planning and Scheduling

- Quality Control and Assurance

- Design for Manufacturing (DFM)

- Project Management

- Lean Manufacturing

- Six Sigma

Work Experience

Engineering Production Liaison

- Led crossfunctional initiatives to improve product quality and reduce production defects.

- Assessed production capabilities and provided technical recommendations to optimize manufacturing processes.

- Collaborated with design engineers to resolve technical issues and ensure product manufacturability.

- Developed and maintained production schedules to ensure timely completion of orders.

Engineering Production Liaison

- Collaborated with engineering, production, and quality teams to ensure seamless product development and manufacturing processes.

- Developed and implemented communication protocols to facilitate effective information exchange between departments.

- Managed supplier relationships and facilitated ontime delivery of critical components.

- Analyzed production data to identify bottlenecks and implemented corrective measures to optimize efficiency.

Accomplishments

- Successfully implemented a new production process, reducing lead times by 15% and improving quality by 10%.

- Developed a robust supplier evaluation system, ensuring adherence to quality standards and optimizing procurement efficiency.

- Established a comprehensive production planning and scheduling system, optimizing resource allocation and minimizing production bottlenecks.

- Successfully resolved a complex production issue, mitigating potential disruptions and ensuring ontime delivery of critical components.

- Developed and implemented a production monitoring system, enabling realtime visibility of production progress and facilitating proactive decisionmaking.

Awards

- Awarded the Engineering Production Excellence Award for outstanding contributions to product development and production efficiency.

- Recognized for exceptional collaboration with crossfunctional teams, fostering seamless communication and streamlining production processes.

- Received the Innovation Award for developing a novel production method that significantly reduced costs and improved product performance.

- Awarded the Engineering Production Leadership Award for exceptional guidance and mentorship to engineering and production teams.

Certificates

- Certified Production Scheduler (CPS)

- Certified Quality Engineer (CQE)

- Certified Manufacturing Engineer (CMfgE)

- Certified Lean Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Engineering Production Liaison

- Highlight your technical skills and experience in production planning, quality control, and design for manufacturing (DFM).

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your project management and leadership skills, emphasizing your ability to manage cross-functional teams.

- Tailor your resume to each job application, highlighting the skills and experience that are most relevant to the specific role.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Engineering Production Liaison Resume

- Collaborate with engineering, production, and quality teams to ensure seamless product development and manufacturing processes.

- Develop and implement communication protocols to facilitate effective information exchange between departments.

- Manage supplier relationships and facilitate on-time delivery of critical components.

- Analyze production data to identify bottlenecks and implement corrective measures to optimize efficiency.

- Lead cross-functional initiatives to improve product quality and reduce production defects.

- Assess production capabilities and provide technical recommendations to optimize manufacturing processes.

- Collaborate with design engineers to resolve technical issues and ensure product manufacturability.

Frequently Asked Questions (FAQ’s) For Engineering Production Liaison

What is the role of an Engineering Production Liaison?

An Engineering Production Liaison is responsible for coordinating and facilitating communication between engineering, production, and quality teams to ensure the smooth development and production of products.

What skills are required for this role?

Engineering Production Liaisons typically require a Bachelor’s degree in Industrial Engineering or a related field, as well as experience in production planning, quality control, and project management.

What are the career prospects for Engineering Production Liaisons?

Engineering Production Liaisons can advance to management positions within the manufacturing industry, such as Production Manager or Plant Manager.

What is the salary range for Engineering Production Liaisons?

The salary range for Engineering Production Liaisons varies depending on experience, location, and company size, but typically falls between $70,000 and $120,000 per year.

What are the challenges faced by Engineering Production Liaisons?

Engineering Production Liaisons may face challenges such as managing complex projects, resolving technical issues, and coordinating between different departments.

What are the opportunities for Engineering Production Liaisons?

Engineering Production Liaisons have the opportunity to work on a variety of projects, gain exposure to different aspects of the manufacturing process, and contribute to the success of their organization.