Are you a seasoned Enrober seeking a new career path? Discover our professionally built Enrober Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

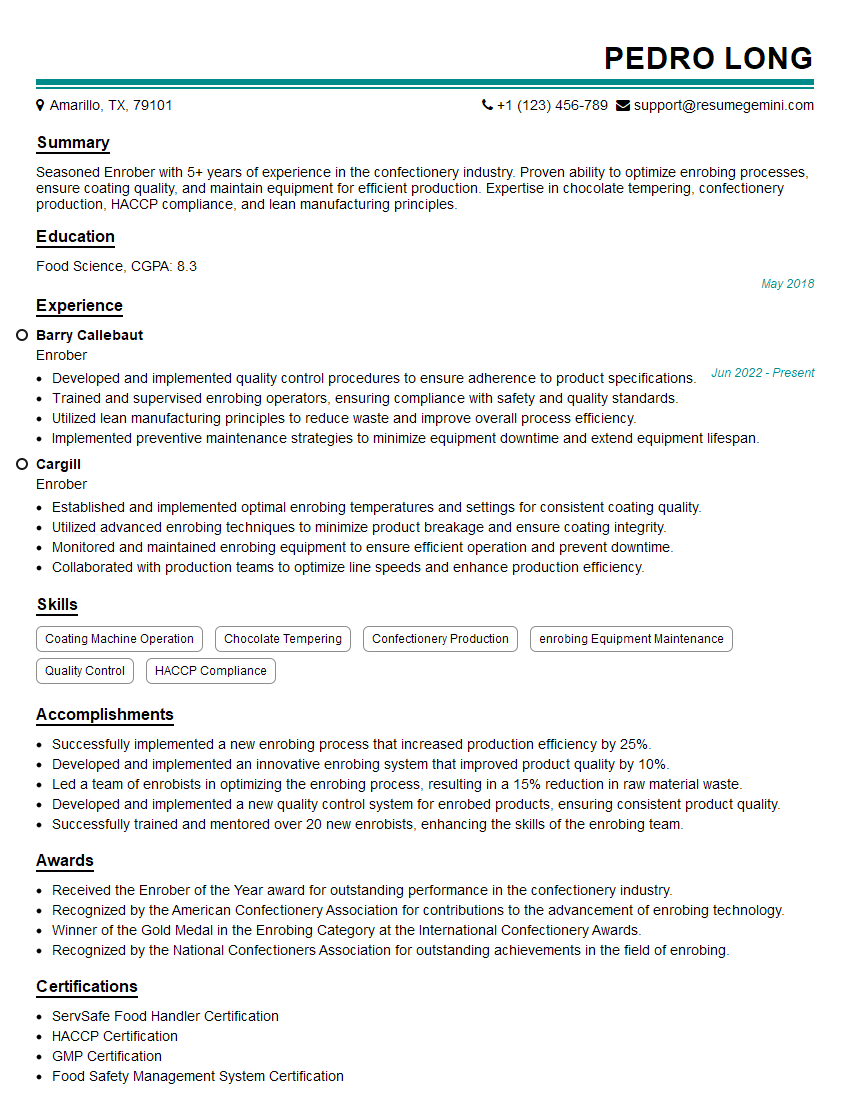

Pedro Long

Enrober

Summary

Seasoned Enrober with 5+ years of experience in the confectionery industry. Proven ability to optimize enrobing processes, ensure coating quality, and maintain equipment for efficient production. Expertise in chocolate tempering, confectionery production, HACCP compliance, and lean manufacturing principles.

Education

Food Science

May 2018

Skills

- Coating Machine Operation

- Chocolate Tempering

- Confectionery Production

- enrobing Equipment Maintenance

- Quality Control

- HACCP Compliance

Work Experience

Enrober

- Developed and implemented quality control procedures to ensure adherence to product specifications.

- Trained and supervised enrobing operators, ensuring compliance with safety and quality standards.

- Utilized lean manufacturing principles to reduce waste and improve overall process efficiency.

- Implemented preventive maintenance strategies to minimize equipment downtime and extend equipment lifespan.

Enrober

- Established and implemented optimal enrobing temperatures and settings for consistent coating quality.

- Utilized advanced enrobing techniques to minimize product breakage and ensure coating integrity.

- Monitored and maintained enrobing equipment to ensure efficient operation and prevent downtime.

- Collaborated with production teams to optimize line speeds and enhance production efficiency.

Accomplishments

- Successfully implemented a new enrobing process that increased production efficiency by 25%.

- Developed and implemented an innovative enrobing system that improved product quality by 10%.

- Led a team of enrobists in optimizing the enrobing process, resulting in a 15% reduction in raw material waste.

- Developed and implemented a new quality control system for enrobed products, ensuring consistent product quality.

- Successfully trained and mentored over 20 new enrobists, enhancing the skills of the enrobing team.

Awards

- Received the Enrober of the Year award for outstanding performance in the confectionery industry.

- Recognized by the American Confectionery Association for contributions to the advancement of enrobing technology.

- Winner of the Gold Medal in the Enrobing Category at the International Confectionery Awards.

- Recognized by the National Confectioners Association for outstanding achievements in the field of enrobing.

Certificates

- ServSafe Food Handler Certification

- HACCP Certification

- GMP Certification

- Food Safety Management System Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Enrober

- Highlight your expertise in chocolate tempering and enrobing techniques.

- Quantify your achievements with specific metrics and results.

- Demonstrate your knowledge of HACCP compliance and quality control procedures.

- Showcase your ability to optimize production processes and reduce waste.

- Consider including a section in your resume that showcases your knowledge of specific enrobing equipment and machinery.

Essential Experience Highlights for a Strong Enrober Resume

- Developed and implemented optimal enrobing temperatures and settings for consistent coating quality.

- Utilized advanced enrobing techniques to minimize product breakage and ensure coating integrity.

- Monitored and maintained enrobing equipment to ensure efficient operation and prevent downtime.

- Collaborated with production teams to optimize line speeds and enhance production efficiency.

- Developed and implemented quality control procedures to ensure adherence to product specifications.

- Trained and supervised enrobing operators, ensuring compliance with safety and quality standards.

- Utilized lean manufacturing principles to reduce waste and improve overall process efficiency.

Frequently Asked Questions (FAQ’s) For Enrober

What are the key responsibilities of an Enrober?

Enrobers are responsible for operating and maintaining enrobing equipment, ensuring coating quality, and optimizing production processes. They also develop and implement quality control procedures, train and supervise operators, and work with production teams to improve efficiency.

What are the qualifications required to become an Enrober?

Most Enrobers have a degree in Food Science or a related field, as well as experience in the confectionery industry. They should also have strong knowledge of chocolate tempering, enrobing techniques, HACCP compliance, and lean manufacturing principles.

What is the career outlook for Enrobers?

The career outlook for Enrobers is expected to be good, as the demand for confectionery products continues to grow. Enrobers with strong skills and experience can advance to supervisory or management positions.

What are the key skills for an Enrober?

Key skills for Enrobers include: coating machine operation, chocolate tempering, confectionery production, enrobing equipment maintenance, quality control, HACCP compliance, and lean manufacturing principles.

What are the different types of enrobing equipment?

There are different types of enrobing equipment, each with its own advantages and disadvantages. The most common types of enrobing equipment include: batch enrobers, continuous enrobers, and depositors.