Are you a seasoned Enrobing Machine Feeder seeking a new career path? Discover our professionally built Enrobing Machine Feeder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

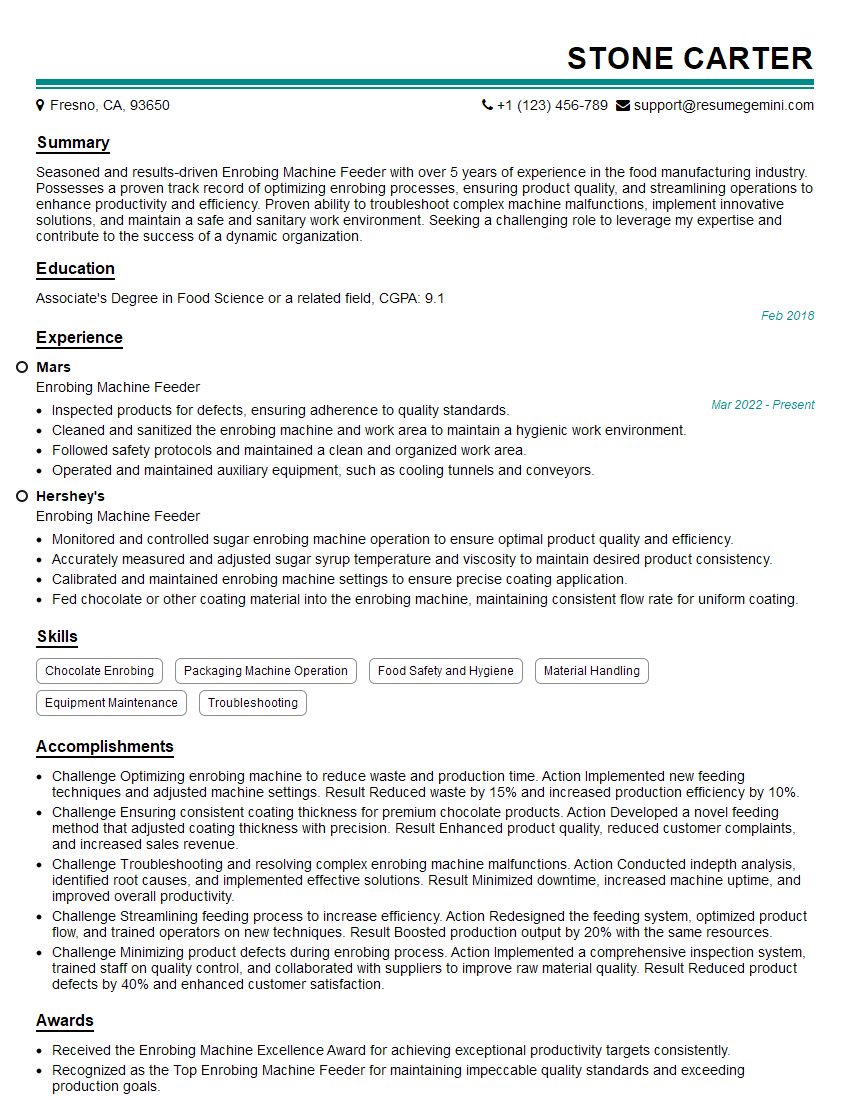

Stone Carter

Enrobing Machine Feeder

Summary

Seasoned and results-driven Enrobing Machine Feeder with over 5 years of experience in the food manufacturing industry. Possesses a proven track record of optimizing enrobing processes, ensuring product quality, and streamlining operations to enhance productivity and efficiency. Proven ability to troubleshoot complex machine malfunctions, implement innovative solutions, and maintain a safe and sanitary work environment. Seeking a challenging role to leverage my expertise and contribute to the success of a dynamic organization.

Education

Associate’s Degree in Food Science or a related field

February 2018

Skills

- Chocolate Enrobing

- Packaging Machine Operation

- Food Safety and Hygiene

- Material Handling

- Equipment Maintenance

- Troubleshooting

Work Experience

Enrobing Machine Feeder

- Inspected products for defects, ensuring adherence to quality standards.

- Cleaned and sanitized the enrobing machine and work area to maintain a hygienic work environment.

- Followed safety protocols and maintained a clean and organized work area.

- Operated and maintained auxiliary equipment, such as cooling tunnels and conveyors.

Enrobing Machine Feeder

- Monitored and controlled sugar enrobing machine operation to ensure optimal product quality and efficiency.

- Accurately measured and adjusted sugar syrup temperature and viscosity to maintain desired product consistency.

- Calibrated and maintained enrobing machine settings to ensure precise coating application.

- Fed chocolate or other coating material into the enrobing machine, maintaining consistent flow rate for uniform coating.

Accomplishments

- Challenge Optimizing enrobing machine to reduce waste and production time. Action Implemented new feeding techniques and adjusted machine settings. Result Reduced waste by 15% and increased production efficiency by 10%.

- Challenge Ensuring consistent coating thickness for premium chocolate products. Action Developed a novel feeding method that adjusted coating thickness with precision. Result Enhanced product quality, reduced customer complaints, and increased sales revenue.

- Challenge Troubleshooting and resolving complex enrobing machine malfunctions. Action Conducted indepth analysis, identified root causes, and implemented effective solutions. Result Minimized downtime, increased machine uptime, and improved overall productivity.

- Challenge Streamlining feeding process to increase efficiency. Action Redesigned the feeding system, optimized product flow, and trained operators on new techniques. Result Boosted production output by 20% with the same resources.

- Challenge Minimizing product defects during enrobing process. Action Implemented a comprehensive inspection system, trained staff on quality control, and collaborated with suppliers to improve raw material quality. Result Reduced product defects by 40% and enhanced customer satisfaction.

Awards

- Received the Enrobing Machine Excellence Award for achieving exceptional productivity targets consistently.

- Recognized as the Top Enrobing Machine Feeder for maintaining impeccable quality standards and exceeding production goals.

- Received the Safety Star Award for adhering to all safety regulations and maintaining a hazardfree work environment.

- Recognized for Continuous Improvement Excellence for actively suggesting and implementing process enhancements.

Certificates

- ServSafe Food Handling Certification

- Forklift Operator Certification

- Hazard Analysis and Critical Control Points (HACCP) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Enrobing Machine Feeder

- Highlight your experience and skills in optimizing enrobing machine performance and reducing waste.

- Quantify your accomplishments with specific metrics, such as percentage reduction in waste or increase in production efficiency.

- Emphasize your ability to troubleshoot and resolve complex machine malfunctions, providing specific examples of successful problem-solving.

- Showcase your understanding of food safety and hygiene regulations and your commitment to maintaining a clean and sanitary work environment.

- Demonstrate your willingness to learn and adapt to new technologies and advancements in the food manufacturing industry.

Essential Experience Highlights for a Strong Enrobing Machine Feeder Resume

- Operate and monitor enrobing machines to coat food products with chocolate, candy, or other coatings

- Adjust machine settings and troubleshoot malfunctions to ensure optimal performance and product quality

- Inspect products to ensure they meet quality standards and specifications

- Maintain a clean and sanitary work area to comply with food safety regulations

- Train and supervise junior staff on enrobing machine operation and maintenance

- Collaborate with quality control and production teams to optimize processes and improve product quality

- Keep detailed records of production and maintenance activities

Frequently Asked Questions (FAQ’s) For Enrobing Machine Feeder

What are the key skills and qualities required for an Enrobing Machine Feeder?

The key skills and qualities required for an Enrobing Machine Feeder include: strong attention to detail, ability to operate and maintain enrobing machines, knowledge of food safety and hygiene regulations, problem-solving skills, and a commitment to quality control.

What are the career prospects for an Enrobing Machine Feeder?

Enrobing Machine Feeders can advance to supervisory roles, such as Production Supervisor or Quality Control Supervisor. With additional experience and training, they may also become Enrobing Machine Operators or Food Production Managers.

What is the work environment like for an Enrobing Machine Feeder?

Enrobing Machine Feeders typically work in food manufacturing plants. The work environment is often fast-paced and requires the ability to work independently and as part of a team. Enrobing Machine Feeders must also be able to work in a cold and humid environment.

What are the physical demands of being an Enrobing Machine Feeder?

Enrobing Machine Feeders must be able to stand for long periods of time and lift heavy objects. They must also be able to work in a cold and humid environment.

What are the educational requirements for an Enrobing Machine Feeder?

Most Enrobing Machine Feeders have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in food science or a related field.

What are the safety hazards associated with being an Enrobing Machine Feeder?

Enrobing Machine Feeders must be aware of the following safety hazards: moving machinery, electrical hazards, and chemical hazards. They must also be able to work in a cold and humid environment.

What are the benefits of being an Enrobing Machine Feeder?

The benefits of being an Enrobing Machine Feeder include: job security, opportunities for advancement, and a competitive salary.

What are the challenges of being an Enrobing Machine Feeder?

The challenges of being an Enrobing Machine Feeder include: working in a fast-paced and demanding environment, working in a cold and humid environment, and dealing with repetitive tasks.