Are you a seasoned Fabrication Operator seeking a new career path? Discover our professionally built Fabrication Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

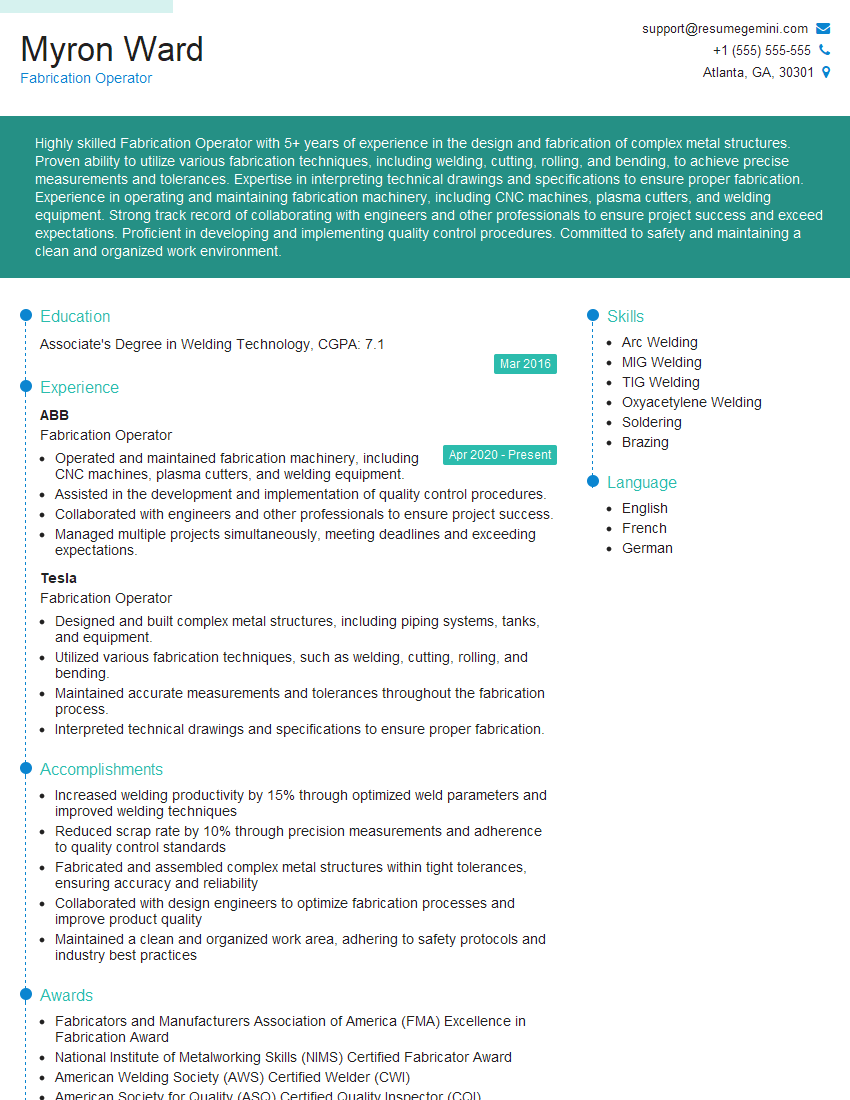

Myron Ward

Fabrication Operator

Summary

Highly skilled Fabrication Operator with 5+ years of experience in the design and fabrication of complex metal structures. Proven ability to utilize various fabrication techniques, including welding, cutting, rolling, and bending, to achieve precise measurements and tolerances. Expertise in interpreting technical drawings and specifications to ensure proper fabrication. Experience in operating and maintaining fabrication machinery, including CNC machines, plasma cutters, and welding equipment. Strong track record of collaborating with engineers and other professionals to ensure project success and exceed expectations. Proficient in developing and implementing quality control procedures. Committed to safety and maintaining a clean and organized work environment.

Education

Associate’s Degree in Welding Technology

March 2016

Skills

- Arc Welding

- MIG Welding

- TIG Welding

- Oxyacetylene Welding

- Soldering

- Brazing

Work Experience

Fabrication Operator

- Operated and maintained fabrication machinery, including CNC machines, plasma cutters, and welding equipment.

- Assisted in the development and implementation of quality control procedures.

- Collaborated with engineers and other professionals to ensure project success.

- Managed multiple projects simultaneously, meeting deadlines and exceeding expectations.

Fabrication Operator

- Designed and built complex metal structures, including piping systems, tanks, and equipment.

- Utilized various fabrication techniques, such as welding, cutting, rolling, and bending.

- Maintained accurate measurements and tolerances throughout the fabrication process.

- Interpreted technical drawings and specifications to ensure proper fabrication.

Accomplishments

- Increased welding productivity by 15% through optimized weld parameters and improved welding techniques

- Reduced scrap rate by 10% through precision measurements and adherence to quality control standards

- Fabricated and assembled complex metal structures within tight tolerances, ensuring accuracy and reliability

- Collaborated with design engineers to optimize fabrication processes and improve product quality

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices

Awards

- Fabricators and Manufacturers Association of America (FMA) Excellence in Fabrication Award

- National Institute of Metalworking Skills (NIMS) Certified Fabricator Award

- American Welding Society (AWS) Certified Welder (CWI)

- American Society for Quality (ASQ) Certified Quality Inspector (CQI)

Certificates

- AWS Certified Welder

- ISO 9001 Certification

- ASME Code Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fabrication Operator

- Highlight your welding skills and experience in your resume.

- Showcase your knowledge of different fabrication techniques.

- Emphasize your ability to read and interpret technical drawings.

- Provide examples of projects you have worked on and the results you achieved.

Essential Experience Highlights for a Strong Fabrication Operator Resume

- Designed and built complex metal structures, including piping systems, tanks, and equipment.

- Utilized various fabrication techniques, such as welding, cutting, rolling, and bending.

- Maintained accurate measurements and tolerances throughout the fabrication process.

- Interpreted technical drawings and specifications to ensure proper fabrication.

- Operated and maintained fabrication machinery, including CNC machines, plasma cutters, and welding equipment.

- Assisted in the development and implementation of quality control procedures.

- Collaborated with engineers and other professionals to ensure project success.

Frequently Asked Questions (FAQ’s) For Fabrication Operator

What are the key skills required to be a successful Fabrication Operator?

Key skills include welding, cutting, rolling, bending, and operating fabrication machinery.

What is the work environment of a Fabrication Operator like?

Fabrication Operators typically work in a manufacturing or fabrication shop, often in close proximity to machinery and equipment.

What are the career prospects for Fabrication Operators?

Fabrication Operators can advance to positions such as Lead Fabricator, Supervisor, or Quality Control Inspector.

What are the safety precautions that Fabrication Operators must follow?

Fabrication Operators must follow safety protocols, such as wearing appropriate protective gear, using equipment properly, and maintaining a clean and organized work area.

What are the different industries that Fabrication Operators can work in?

Fabrication Operators can find employment in industries such as construction, manufacturing, automotive, and aerospace.