Are you a seasoned Factory Assembler seeking a new career path? Discover our professionally built Factory Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

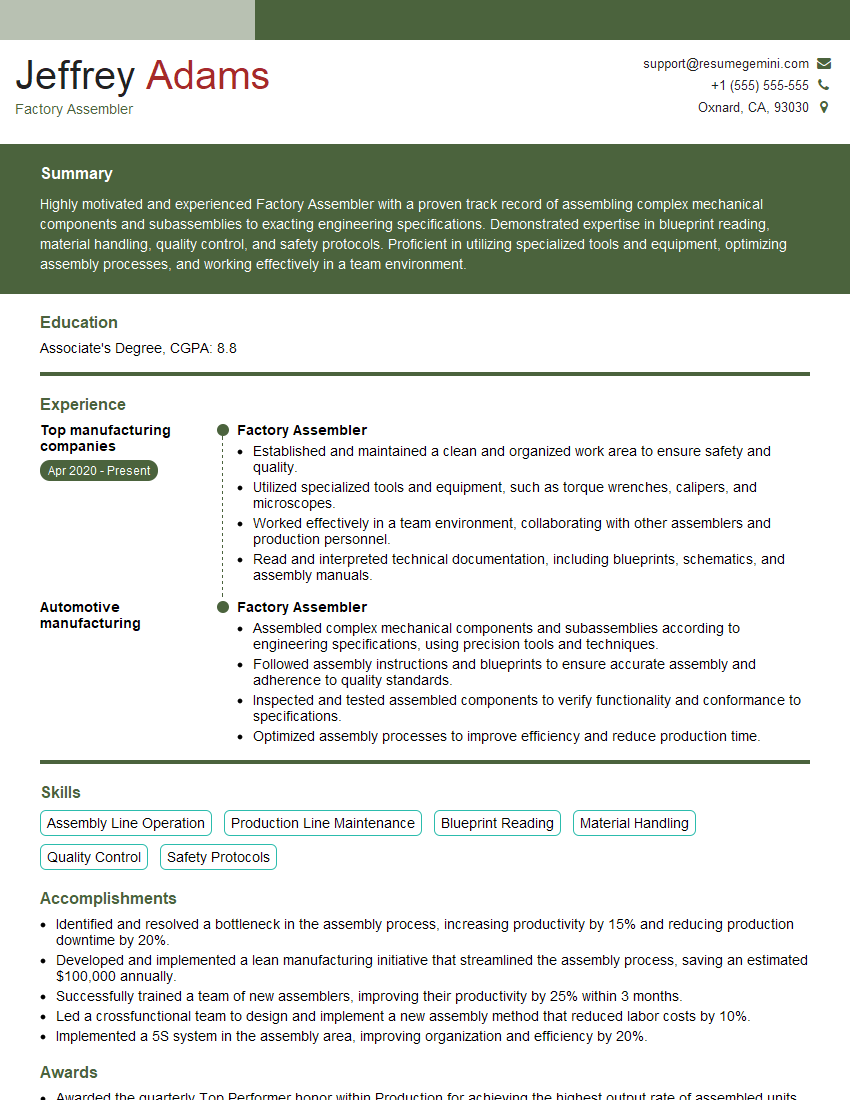

Jeffrey Adams

Factory Assembler

Summary

Highly motivated and experienced Factory Assembler with a proven track record of assembling complex mechanical components and subassemblies to exacting engineering specifications. Demonstrated expertise in blueprint reading, material handling, quality control, and safety protocols. Proficient in utilizing specialized tools and equipment, optimizing assembly processes, and working effectively in a team environment.

Education

Associate’s Degree

March 2016

Skills

- Assembly Line Operation

- Production Line Maintenance

- Blueprint Reading

- Material Handling

- Quality Control

- Safety Protocols

Work Experience

Factory Assembler

- Established and maintained a clean and organized work area to ensure safety and quality.

- Utilized specialized tools and equipment, such as torque wrenches, calipers, and microscopes.

- Worked effectively in a team environment, collaborating with other assemblers and production personnel.

- Read and interpreted technical documentation, including blueprints, schematics, and assembly manuals.

Factory Assembler

- Assembled complex mechanical components and subassemblies according to engineering specifications, using precision tools and techniques.

- Followed assembly instructions and blueprints to ensure accurate assembly and adherence to quality standards.

- Inspected and tested assembled components to verify functionality and conformance to specifications.

- Optimized assembly processes to improve efficiency and reduce production time.

Accomplishments

- Identified and resolved a bottleneck in the assembly process, increasing productivity by 15% and reducing production downtime by 20%.

- Developed and implemented a lean manufacturing initiative that streamlined the assembly process, saving an estimated $100,000 annually.

- Successfully trained a team of new assemblers, improving their productivity by 25% within 3 months.

- Led a crossfunctional team to design and implement a new assembly method that reduced labor costs by 10%.

- Implemented a 5S system in the assembly area, improving organization and efficiency by 20%.

Awards

- Awarded the quarterly Top Performer honor within Production for achieving the highest output rate of assembled units, consistently exceeding quality standards.

- Recognized as Employee of the Month for exceptional contributions to the assembly line, reducing assembly time by 12% through process optimization.

- Received the Safety Excellence Award for maintaining an exemplary safety record and promoting a safe work environment.

- Awarded the Team Excellence Award for exceptional collaboration and teamwork in completing a complex assembly project.

Certificates

- OSHA Safety Certification

- ISO 9001 Quality Management Certification

- Lean Manufacturing Certification

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Factory Assembler

- Highlight your technical skills and experience in blueprint reading, material handling, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your teamwork and communication skills, as these are essential for success in a factory assembly environment.

- Emphasize your commitment to safety and quality, as these are top priorities in any manufacturing setting.

Essential Experience Highlights for a Strong Factory Assembler Resume

- Assembled complex mechanical components and subassemblies according to engineering specifications.

- Followed assembly instructions and blueprints to ensure accurate assembly and adherence to quality standards.

- Inspected and tested assembled components to verify functionality and conformance to specifications.

- Optimized assembly processes to improve efficiency and reduce production time.

- Established and maintained a clean and organized work area to ensure safety and quality.

- Utilized specialized tools and equipment, such as torque wrenches, calipers, and microscopes.

- Worked effectively in a team environment, collaborating with other assemblers and production personnel.

Frequently Asked Questions (FAQ’s) For Factory Assembler

What are the key skills required to be a successful Factory Assembler?

The key skills required to be a successful Factory Assembler include blueprint reading, material handling, quality control, safety protocols, and the ability to work effectively in a team environment.

What are the typical working conditions for a Factory Assembler?

Factory Assemblers typically work in a fast-paced, production-oriented environment. They may be required to stand for long periods of time and perform repetitive tasks.

What are the career advancement opportunities for a Factory Assembler?

Factory Assemblers may advance to positions such as Team Leader, Supervisor, or Quality Control Inspector.

What is the job outlook for Factory Assemblers?

The job outlook for Factory Assemblers is expected to be stable over the next few years.

What are the benefits of working as a Factory Assembler?

The benefits of working as a Factory Assembler include job stability, opportunities for advancement, and a competitive salary.

How can I prepare for a career as a Factory Assembler?

To prepare for a career as a Factory Assembler, you can complete an associate’s degree or certificate program in manufacturing or a related field.

What are the challenges of working as a Factory Assembler?

The challenges of working as a Factory Assembler include working in a fast-paced, production-oriented environment, performing repetitive tasks, and standing for long periods of time.

What are the physical demands of being a Factory Assembler?

Factory Assemblers may be required to stand for long periods of time, lift heavy objects, and perform repetitive tasks.