Are you a seasoned Factory Engineer seeking a new career path? Discover our professionally built Factory Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

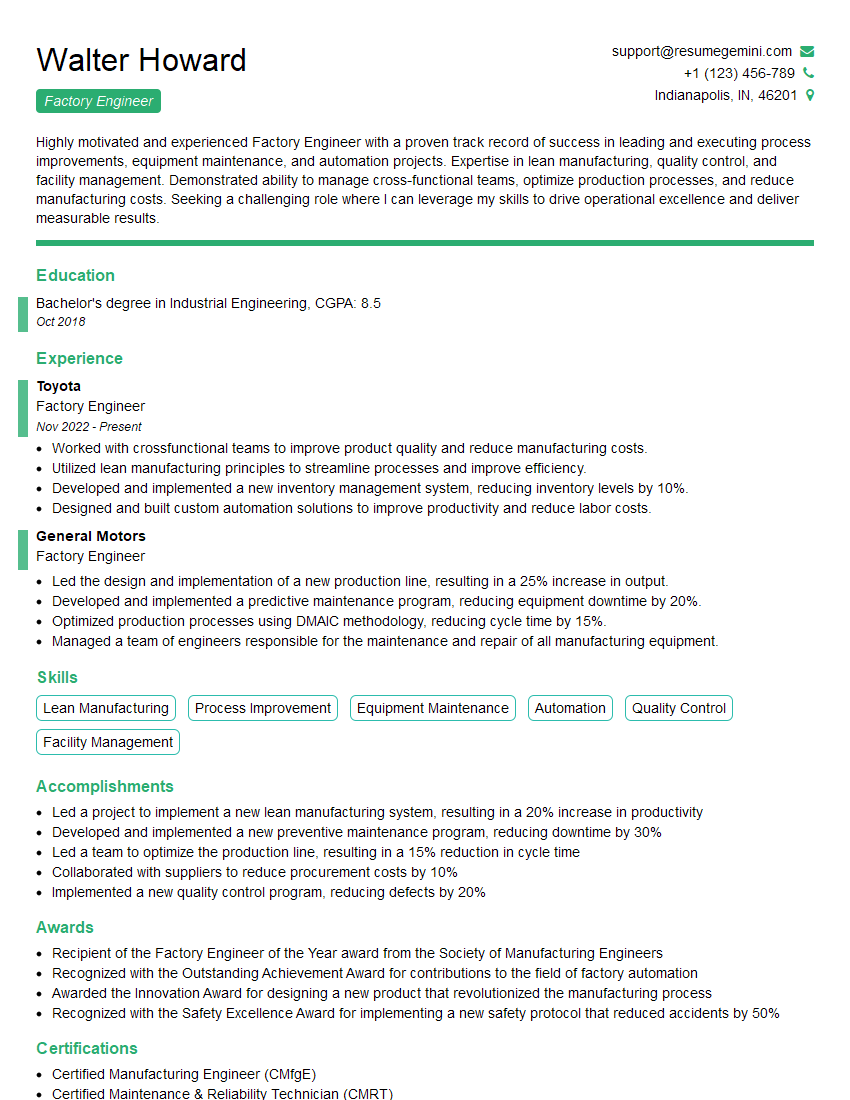

Walter Howard

Factory Engineer

Summary

Highly motivated and experienced Factory Engineer with a proven track record of success in leading and executing process improvements, equipment maintenance, and automation projects. Expertise in lean manufacturing, quality control, and facility management. Demonstrated ability to manage cross-functional teams, optimize production processes, and reduce manufacturing costs. Seeking a challenging role where I can leverage my skills to drive operational excellence and deliver measurable results.

Education

Bachelor’s degree in Industrial Engineering

October 2018

Skills

- Lean Manufacturing

- Process Improvement

- Equipment Maintenance

- Automation

- Quality Control

- Facility Management

Work Experience

Factory Engineer

- Worked with crossfunctional teams to improve product quality and reduce manufacturing costs.

- Utilized lean manufacturing principles to streamline processes and improve efficiency.

- Developed and implemented a new inventory management system, reducing inventory levels by 10%.

- Designed and built custom automation solutions to improve productivity and reduce labor costs.

Factory Engineer

- Led the design and implementation of a new production line, resulting in a 25% increase in output.

- Developed and implemented a predictive maintenance program, reducing equipment downtime by 20%.

- Optimized production processes using DMAIC methodology, reducing cycle time by 15%.

- Managed a team of engineers responsible for the maintenance and repair of all manufacturing equipment.

Accomplishments

- Led a project to implement a new lean manufacturing system, resulting in a 20% increase in productivity

- Developed and implemented a new preventive maintenance program, reducing downtime by 30%

- Led a team to optimize the production line, resulting in a 15% reduction in cycle time

- Collaborated with suppliers to reduce procurement costs by 10%

- Implemented a new quality control program, reducing defects by 20%

Awards

- Recipient of the Factory Engineer of the Year award from the Society of Manufacturing Engineers

- Recognized with the Outstanding Achievement Award for contributions to the field of factory automation

- Awarded the Innovation Award for designing a new product that revolutionized the manufacturing process

- Recognized with the Safety Excellence Award for implementing a new safety protocol that reduced accidents by 50%

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Maintenance & Reliability Technician (CMRT)

- Certified Production Technician (CPT)

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Factory Engineer

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Highlight your skills in lean manufacturing, process improvement, and automation, as they are highly sought after in the industry.

- Showcase your ability to manage and motivate teams, as collaboration is essential in factory engineering.

- Emphasize your experience in implementing and maintaining predictive maintenance programs, as they are crucial for reducing downtime and improving equipment reliability.

Essential Experience Highlights for a Strong Factory Engineer Resume

- Lead the design, implementation, and maintenance of production lines to increase output and efficiency.

- Develop and implement preventive and predictive maintenance programs to minimize equipment downtime and ensure optimal performance.

- Utilize lean manufacturing principles to streamline processes, reduce cycle time, and eliminate waste.

- Manage a team of engineers responsible for the maintenance and repair of all manufacturing equipment, ensuring smooth operations.

- Collaborate with cross-functional teams to improve product quality, reduce manufacturing costs, and enhance customer satisfaction.

- Design and implement automation solutions to increase productivity, reduce labor costs, and improve safety.

- Develop and implement inventory management systems to optimize inventory levels, reduce waste, and ensure just-in-time delivery.

Frequently Asked Questions (FAQ’s) For Factory Engineer

What are the key skills required for a successful Factory Engineer?

Factory Engineers require a strong foundation in lean manufacturing, process improvement, equipment maintenance, automation, quality control, and facility management.

What is the role of a Factory Engineer in improving productivity?

Factory Engineers play a pivotal role in improving productivity by optimizing production processes, implementing automation solutions, and reducing waste through lean manufacturing principles, resulting in increased output and efficiency.

How does a Factory Engineer contribute to quality control?

Factory Engineers are responsible for developing and implementing quality control measures throughout the manufacturing process, ensuring that products meet specifications and customer requirements.

What is the importance of facility management for a Factory Engineer?

Factory Engineers are responsible for managing and maintaining the physical infrastructure of a manufacturing facility, including equipment, buildings, and utilities, to ensure a safe and efficient work environment.

How can a Factory Engineer leverage technology to enhance operations?

Factory Engineers leverage technology, such as automation, predictive maintenance, and data analytics, to improve production efficiency, reduce downtime, and optimize resource allocation.

What are the career advancement opportunities for a Factory Engineer?

Factory Engineers with experience and expertise can advance to roles such as Production Manager, Plant Manager, or Operations Manager, overseeing larger-scale manufacturing operations and strategic decision-making.