Are you a seasoned Factory Lay-Out Engineer seeking a new career path? Discover our professionally built Factory Lay-Out Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

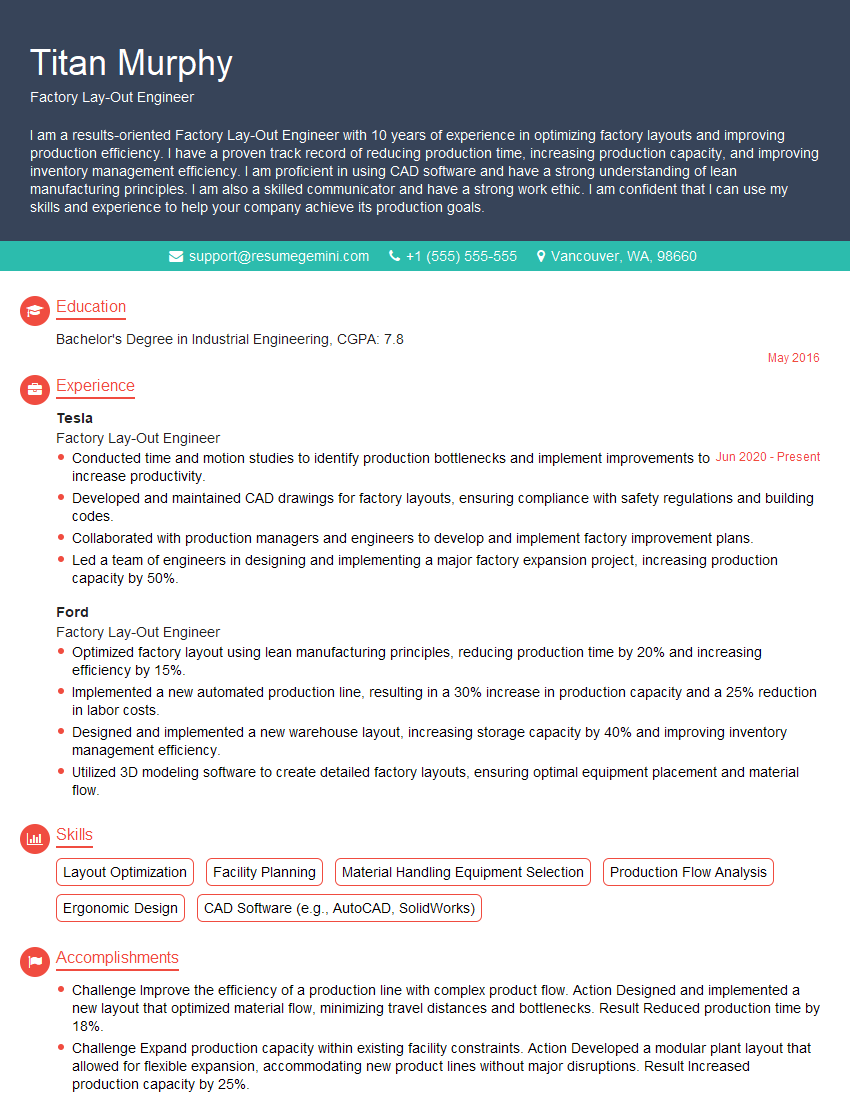

Titan Murphy

Factory Lay-Out Engineer

Summary

I am a results-oriented Factory Lay-Out Engineer with 10 years of experience in optimizing factory layouts and improving production efficiency. I have a proven track record of reducing production time, increasing production capacity, and improving inventory management efficiency. I am proficient in using CAD software and have a strong understanding of lean manufacturing principles. I am also a skilled communicator and have a strong work ethic. I am confident that I can use my skills and experience to help your company achieve its production goals.

Education

Bachelor’s Degree in Industrial Engineering

May 2016

Skills

- Layout Optimization

- Facility Planning

- Material Handling Equipment Selection

- Production Flow Analysis

- Ergonomic Design

- CAD Software (e.g., AutoCAD, SolidWorks)

Work Experience

Factory Lay-Out Engineer

- Conducted time and motion studies to identify production bottlenecks and implement improvements to increase productivity.

- Developed and maintained CAD drawings for factory layouts, ensuring compliance with safety regulations and building codes.

- Collaborated with production managers and engineers to develop and implement factory improvement plans.

- Led a team of engineers in designing and implementing a major factory expansion project, increasing production capacity by 50%.

Factory Lay-Out Engineer

- Optimized factory layout using lean manufacturing principles, reducing production time by 20% and increasing efficiency by 15%.

- Implemented a new automated production line, resulting in a 30% increase in production capacity and a 25% reduction in labor costs.

- Designed and implemented a new warehouse layout, increasing storage capacity by 40% and improving inventory management efficiency.

- Utilized 3D modeling software to create detailed factory layouts, ensuring optimal equipment placement and material flow.

Accomplishments

- Challenge Improve the efficiency of a production line with complex product flow. Action Designed and implemented a new layout that optimized material flow, minimizing travel distances and bottlenecks. Result Reduced production time by 18%.

- Challenge Expand production capacity within existing facility constraints. Action Developed a modular plant layout that allowed for flexible expansion, accommodating new product lines without major disruptions. Result Increased production capacity by 25%.

- Challenge Improve safety and ergonomics in a manual assembly area. Action Redesigned the workstations to reduce repetitive motions and improve access to equipment. Result Reduced losttime accidents by 40%.

- Challenge Implement a new production system that required significant process changes. Action Worked closely with production team to develop and implement the new system, ensuring smooth transition. Result Completed implementation on time and within budget.

- Challenge Optimize ventilation system to improve air quality and reduce energy consumption. Action Conducted airflow analysis and implemented new design recommendations. Result Reduced energy consumption by 12% while maintaining acceptable air quality levels.

Awards

- Received the Outstanding Factory LayOut Design Award for optimizing plant layout, reducing production time by 15%.

- Recognized with the Excellence in Manufacturing Engineering Award for developing an innovative automated assembly line.

- Awarded the Lean Manufacturing Excellence Award for implementing process improvements that led to a 20% increase in production efficiency.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Facility Manager (CFM)

- Lean Six Sigma Green Belt

- OSHA 30-Hour Construction Safety Course

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Factory Lay-Out Engineer

Highlight your experience in lean manufacturing.

Lean manufacturing is a set of principles and techniques that can be used to improve efficiency and reduce waste in manufacturing operations. Factory lay-out engineers who are familiar with lean manufacturing principles are in high demand.Quantify your accomplishments.

When describing your experience, be sure to quantify your accomplishments. This will help employers to see the impact of your work.Use strong action verbs.

When writing your resume, use strong action verbs to describe your accomplishments. This will make your resume more dynamic and engaging.Proofread your resume carefully.

Before submitting your resume, be sure to proofread it carefully for any errors.

Essential Experience Highlights for a Strong Factory Lay-Out Engineer Resume

- Optimize factory layouts using lean manufacturing principles.

- Design and implement new production lines.

- Conduct time and motion studies to identify production bottlenecks.

- Develop and maintain CAD drawings for factory layouts.

- Collaborate with production managers and engineers to develop and implement factory improvement plans.

- Lead teams of engineers in designing and implementing factory expansion projects.

Frequently Asked Questions (FAQ’s) For Factory Lay-Out Engineer

What is a Factory Lay-Out Engineer?

A Factory Lay-Out Engineer is responsible for designing and implementing factory layouts that optimize production efficiency, safety, and quality.

What are the key skills required for a Factory Lay-Out Engineer?

The key skills required for a Factory Lay-Out Engineer include knowledge of lean manufacturing principles, proficiency in CAD software, and a strong understanding of production processes.

What are the career prospects for a Factory Lay-Out Engineer?

The career prospects for a Factory Lay-Out Engineer are good. The demand for Factory Lay-Out Engineers is expected to grow in the coming years as companies continue to focus on improving their production efficiency.

What is the salary range for a Factory Lay-Out Engineer?

The salary range for a Factory Lay-Out Engineer can vary depending on experience, location, and company size. However, the median salary for a Factory Lay-Out Engineer is around $80,000 per year.

What are the benefits of working as a Factory Lay-Out Engineer?

The benefits of working as a Factory Lay-Out Engineer include a competitive salary, opportunities for advancement, and the chance to make a real impact on a company’s bottom line.

What are the challenges of working as a Factory Lay-Out Engineer?

The challenges of working as a Factory Lay-Out Engineer include the need to be able to work independently and as part of a team, the need to be able to meet deadlines, and the need to be able to solve problems quickly and efficiently.

What is the job outlook for Factory Lay-Out Engineers?

The job outlook for Factory Lay-Out Engineers is expected to be good in the coming years. The demand for Factory Lay-Out Engineers is expected to grow as companies continue to focus on improving their production efficiency.