Are you a seasoned Factory Superintendent seeking a new career path? Discover our professionally built Factory Superintendent Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

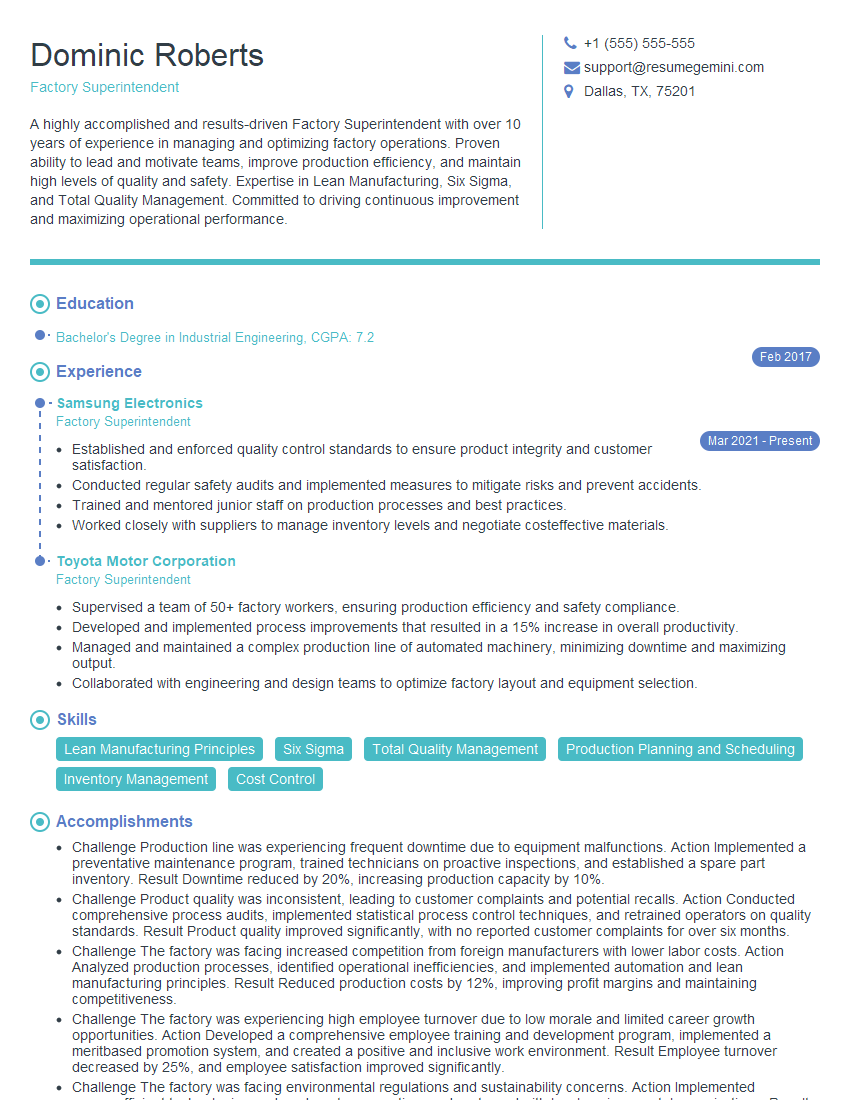

Dominic Roberts

Factory Superintendent

Summary

A highly accomplished and results-driven Factory Superintendent with over 10 years of experience in managing and optimizing factory operations. Proven ability to lead and motivate teams, improve production efficiency, and maintain high levels of quality and safety. Expertise in Lean Manufacturing, Six Sigma, and Total Quality Management. Committed to driving continuous improvement and maximizing operational performance.

Education

Bachelor’s Degree in Industrial Engineering

February 2017

Skills

- Lean Manufacturing Principles

- Six Sigma

- Total Quality Management

- Production Planning and Scheduling

- Inventory Management

- Cost Control

Work Experience

Factory Superintendent

- Established and enforced quality control standards to ensure product integrity and customer satisfaction.

- Conducted regular safety audits and implemented measures to mitigate risks and prevent accidents.

- Trained and mentored junior staff on production processes and best practices.

- Worked closely with suppliers to manage inventory levels and negotiate costeffective materials.

Factory Superintendent

- Supervised a team of 50+ factory workers, ensuring production efficiency and safety compliance.

- Developed and implemented process improvements that resulted in a 15% increase in overall productivity.

- Managed and maintained a complex production line of automated machinery, minimizing downtime and maximizing output.

- Collaborated with engineering and design teams to optimize factory layout and equipment selection.

Accomplishments

- Challenge Production line was experiencing frequent downtime due to equipment malfunctions. Action Implemented a preventative maintenance program, trained technicians on proactive inspections, and established a spare part inventory. Result Downtime reduced by 20%, increasing production capacity by 10%.

- Challenge Product quality was inconsistent, leading to customer complaints and potential recalls. Action Conducted comprehensive process audits, implemented statistical process control techniques, and retrained operators on quality standards. Result Product quality improved significantly, with no reported customer complaints for over six months.

- Challenge The factory was facing increased competition from foreign manufacturers with lower labor costs. Action Analyzed production processes, identified operational inefficiencies, and implemented automation and lean manufacturing principles. Result Reduced production costs by 12%, improving profit margins and maintaining competitiveness.

- Challenge The factory was experiencing high employee turnover due to low morale and limited career growth opportunities. Action Developed a comprehensive employee training and development program, implemented a meritbased promotion system, and created a positive and inclusive work environment. Result Employee turnover decreased by 25%, and employee satisfaction improved significantly.

- Challenge The factory was facing environmental regulations and sustainability concerns. Action Implemented energyefficient technologies, reduced waste generation, and partnered with local environmental organizations. Result Reduced energy consumption by 15%, achieved zerolandfill status, and enhanced the factorys environmental reputation.

Awards

- Recognized with the Factory Excellence Award for outstanding leadership and plant performance improvements.

- Received the Operational Excellence Award for implementing innovative production methods, resulting in a 15% increase in efficiency.

- Honored with the Safety Champion Award for creating a comprehensive safety program that reduced workplace incidents by over 50%.

- Awarded the Manufacturing Leadership Award for successfully implementing a digital transformation strategy, integrating IoT and data analytics into factory operations.

Certificates

- Certified Six Sigma Black Belt

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

- ASQ Certified Manager of Quality/Operational Excellence

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Factory Superintendent

- Quantify your accomplishments: Use specific metrics and data to demonstrate the impact of your contributions. For example, instead of saying “Improved production efficiency,” say “Implemented a new production process that increased output by 15%.”

- Highlight your leadership and management skills: Factory Superintendents are responsible for leading and motivating teams. Emphasize your ability to build strong relationships, delegate effectively, and resolve conflicts.

- Showcase your technical expertise: List your proficiency in relevant software, technologies, and industry best practices. For example, mention your experience with Lean Manufacturing, Six Sigma, and Total Quality Management.

- Proofread carefully: Mistakes on your resume can reflect poorly on your attention to detail and professionalism.

Essential Experience Highlights for a Strong Factory Superintendent Resume

- Managed a team of 50+ factory workers, ensuring production efficiency and safety compliance.

- Developed and implemented process improvements that resulted in a 15% increase in overall productivity.

- Managed and maintained a complex production line of automated machinery, minimizing downtime and maximizing output.

- Collaborated with engineering and design teams to optimize factory layout and equipment selection.

- Established and enforced quality control standards to ensure product integrity and customer satisfaction.

- Conducted regular safety audits and implemented measures to mitigate risks and prevent accidents.

- Trained and mentored junior staff on production processes and best practices.

Frequently Asked Questions (FAQ’s) For Factory Superintendent

What is the role of a Factory Superintendent?

A Factory Superintendent is responsible for managing the day-to-day operations of a factory. This includes overseeing production, quality control, safety, and maintenance. Factory Superintendents work closely with other departments, such as engineering, design, and sales, to ensure that the factory is running smoothly and efficiently.

What qualifications are needed to become a Factory Superintendent?

Most Factory Superintendents have a bachelor’s degree in industrial engineering or a related field. They also typically have several years of experience in manufacturing and production management. Factory Superintendents must have strong leadership, communication, and problem-solving skills.

What are the key responsibilities of a Factory Superintendent?

The key responsibilities of a Factory Superintendent include:

- Planning and scheduling production

- Overseeing quality control

- Ensuring safety compliance

- Managing maintenance and repairs

- Working with other departments to improve efficiency

What are the career prospects for Factory Superintendents?

Factory Superintendents can advance to positions such as Plant Manager, Operations Manager, or General Manager. They may also move into consulting or training roles.

What is the salary range for Factory Superintendents?

The salary range for Factory Superintendents varies depending on experience, location, and company size. According to Salary.com, the median salary for Factory Superintendents in the United States is $95,000.

What are the challenges faced by Factory Superintendents?

Factory Superintendents face a number of challenges, including:

- Managing production in a competitive global market

- Meeting customer demand while maintaining quality standards

- Ensuring safety and compliance in a complex and hazardous environment