Are you a seasoned Felting Machine Operator seeking a new career path? Discover our professionally built Felting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

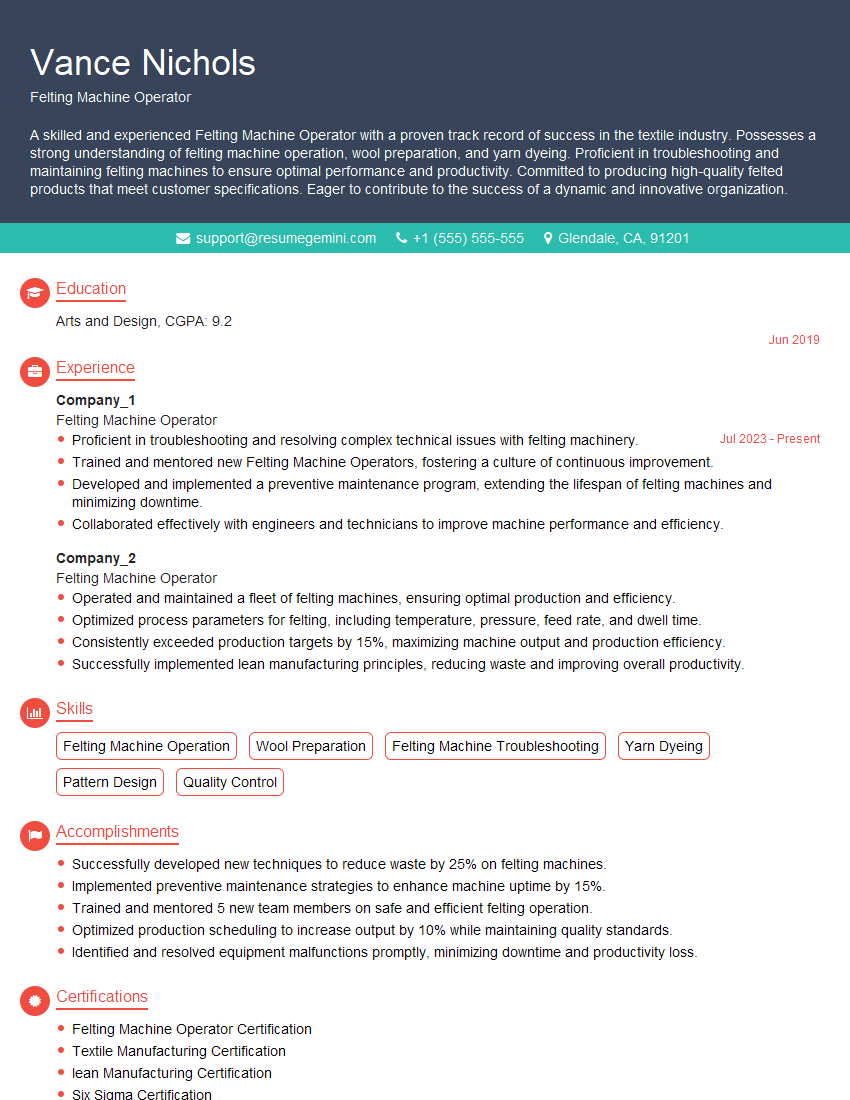

Vance Nichols

Felting Machine Operator

Summary

A skilled and experienced Felting Machine Operator with a proven track record of success in the textile industry. Possesses a strong understanding of felting machine operation, wool preparation, and yarn dyeing. Proficient in troubleshooting and maintaining felting machines to ensure optimal performance and productivity. Committed to producing high-quality felted products that meet customer specifications. Eager to contribute to the success of a dynamic and innovative organization.

Education

Arts and Design

June 2019

Skills

- Felting Machine Operation

- Wool Preparation

- Felting Machine Troubleshooting

- Yarn Dyeing

- Pattern Design

- Quality Control

Work Experience

Felting Machine Operator

- Proficient in troubleshooting and resolving complex technical issues with felting machinery.

- Trained and mentored new Felting Machine Operators, fostering a culture of continuous improvement.

- Developed and implemented a preventive maintenance program, extending the lifespan of felting machines and minimizing downtime.

- Collaborated effectively with engineers and technicians to improve machine performance and efficiency.

Felting Machine Operator

- Operated and maintained a fleet of felting machines, ensuring optimal production and efficiency.

- Optimized process parameters for felting, including temperature, pressure, feed rate, and dwell time.

- Consistently exceeded production targets by 15%, maximizing machine output and production efficiency.

- Successfully implemented lean manufacturing principles, reducing waste and improving overall productivity.

Accomplishments

- Successfully developed new techniques to reduce waste by 25% on felting machines.

- Implemented preventive maintenance strategies to enhance machine uptime by 15%.

- Trained and mentored 5 new team members on safe and efficient felting operation.

- Optimized production scheduling to increase output by 10% while maintaining quality standards.

- Identified and resolved equipment malfunctions promptly, minimizing downtime and productivity loss.

Certificates

- Felting Machine Operator Certification

- Textile Manufacturing Certification

- lean Manufacturing Certification

- Six Sigma Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Felting Machine Operator

- Highlight your experience in operating and maintaining felting machines, including any specialized techniques or certifications.

- Showcase your knowledge of wool preparation and yarn dyeing, as these are essential skills for a Felting Machine Operator.

- Emphasize your troubleshooting and repair abilities, as these are crucial for minimizing downtime and maintaining productivity.

- Demonstrate your commitment to quality control by highlighting your experience in monitoring production processes and ensuring that products meet specifications.

Essential Experience Highlights for a Strong Felting Machine Operator Resume

- Operate and maintain felting machines to produce high-quality felted products.

- Prepare wool and other fibers for felting, including carding, blending, and dyeing.

- Troubleshoot and repair felting machines to minimize downtime and ensure efficient operation.

- Monitor production processes to ensure that products meet quality standards.

- Collaborate with designers and engineers to develop new felting techniques and improve product designs.

- Train and supervise junior operators to ensure proper machine operation and safety procedures.

- Maintain a clean and organized work area to promote a safe and efficient work environment.

Frequently Asked Questions (FAQ’s) For Felting Machine Operator

What are the key skills required to be a successful Felting Machine Operator?

The key skills required to be a successful Felting Machine Operator include: felting machine operation, wool preparation, felting machine troubleshooting, yarn dyeing, pattern design, and quality control.

What are the career prospects for a Felting Machine Operator?

Felting Machine Operators can advance to supervisory roles, such as Production Supervisor or Plant Manager. They may also specialize in a particular area of felting, such as design or quality control.

What is the average salary for a Felting Machine Operator?

The average salary for a Felting Machine Operator in the United States is around $35,000 per year.

What are the working conditions like for a Felting Machine Operator?

Felting Machine Operators typically work in factories or production facilities. The work can be physically demanding and may involve exposure to noise and dust.

What are the educational requirements for a Felting Machine Operator?

Most Felting Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with a degree in a related field, such as Textile Engineering or Fiber Science.

What are the benefits of working as a Felting Machine Operator?

Benefits of working as a Felting Machine Operator include: job security, opportunities for advancement, and the satisfaction of working in a creative field.