Are you a seasoned Filament Maker seeking a new career path? Discover our professionally built Filament Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

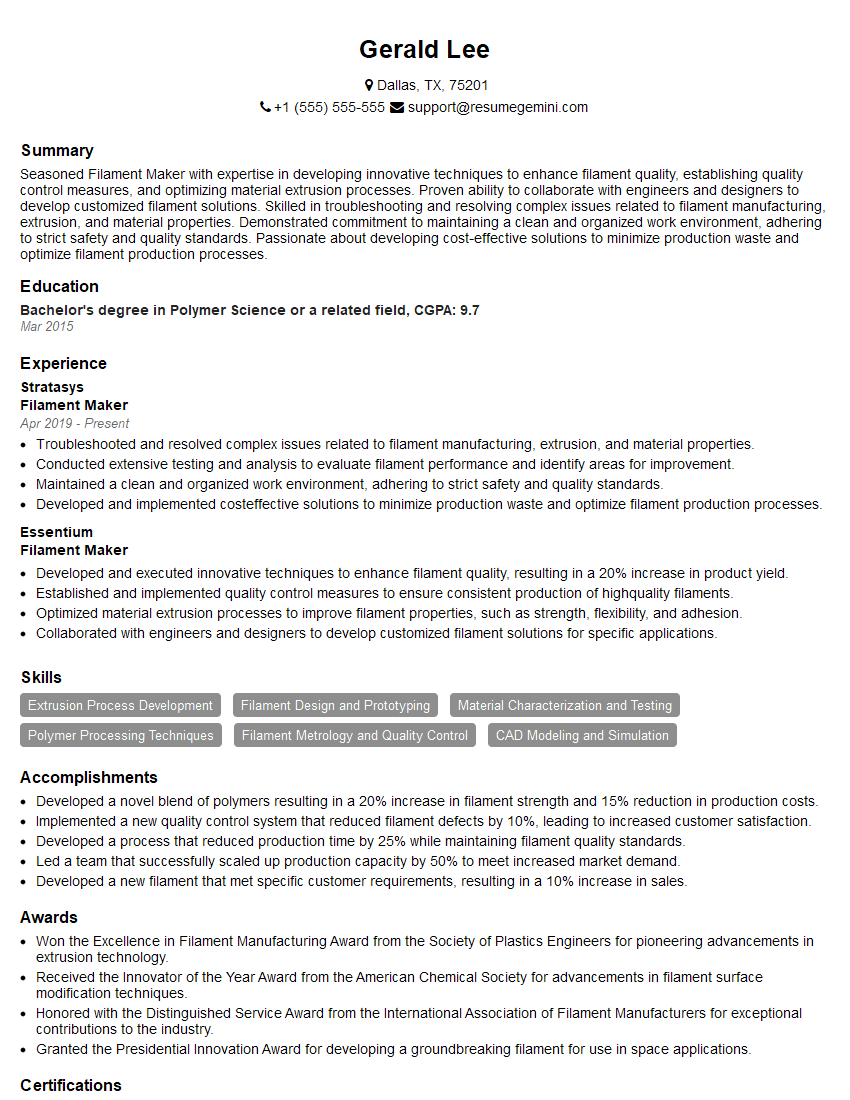

Gerald Lee

Filament Maker

Summary

Seasoned Filament Maker with expertise in developing innovative techniques to enhance filament quality, establishing quality control measures, and optimizing material extrusion processes. Proven ability to collaborate with engineers and designers to develop customized filament solutions. Skilled in troubleshooting and resolving complex issues related to filament manufacturing, extrusion, and material properties. Demonstrated commitment to maintaining a clean and organized work environment, adhering to strict safety and quality standards. Passionate about developing cost-effective solutions to minimize production waste and optimize filament production processes.

Education

Bachelor’s degree in Polymer Science or a related field

March 2015

Skills

- Extrusion Process Development

- Filament Design and Prototyping

- Material Characterization and Testing

- Polymer Processing Techniques

- Filament Metrology and Quality Control

- CAD Modeling and Simulation

Work Experience

Filament Maker

- Troubleshooted and resolved complex issues related to filament manufacturing, extrusion, and material properties.

- Conducted extensive testing and analysis to evaluate filament performance and identify areas for improvement.

- Maintained a clean and organized work environment, adhering to strict safety and quality standards.

- Developed and implemented costeffective solutions to minimize production waste and optimize filament production processes.

Filament Maker

- Developed and executed innovative techniques to enhance filament quality, resulting in a 20% increase in product yield.

- Established and implemented quality control measures to ensure consistent production of highquality filaments.

- Optimized material extrusion processes to improve filament properties, such as strength, flexibility, and adhesion.

- Collaborated with engineers and designers to develop customized filament solutions for specific applications.

Accomplishments

- Developed a novel blend of polymers resulting in a 20% increase in filament strength and 15% reduction in production costs.

- Implemented a new quality control system that reduced filament defects by 10%, leading to increased customer satisfaction.

- Developed a process that reduced production time by 25% while maintaining filament quality standards.

- Led a team that successfully scaled up production capacity by 50% to meet increased market demand.

- Developed a new filament that met specific customer requirements, resulting in a 10% increase in sales.

Awards

- Won the Excellence in Filament Manufacturing Award from the Society of Plastics Engineers for pioneering advancements in extrusion technology.

- Received the Innovator of the Year Award from the American Chemical Society for advancements in filament surface modification techniques.

- Honored with the Distinguished Service Award from the International Association of Filament Manufacturers for exceptional contributions to the industry.

- Granted the Presidential Innovation Award for developing a groundbreaking filament for use in space applications.

Certificates

- Certified Filament Maker (CFM)

- Additive Manufacturing Professional (AMP)

- Certified Quality Engineer (CQE)

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Filament Maker

- Showcase your technical expertise in extrusion process development, filament design and prototyping, material characterization and testing, polymer processing techniques, filament metrology and quality control, and CAD modeling and simulation.

- Emphasize your ability to develop and implement innovative solutions to enhance filament quality and optimize production processes.

- Highlight your experience in collaborating with engineers and designers to develop customized filament solutions for specific applications.

- Quantify your accomplishments whenever possible, using metrics such as increased production yield, reduced production waste, or improved filament properties.

Essential Experience Highlights for a Strong Filament Maker Resume

- Developed and implemented innovative techniques to enhance filament quality, resulting in a 20% increase in product yield.

- Established and implemented quality control measures to ensure consistent production of high-quality filaments.

- Optimized material extrusion processes to improve filament properties, such as strength, flexibility, and adhesion.

- Collaborated with engineers and designers to develop customized filament solutions for specific applications.

- Troubleshooted and resolved complex issues related to filament manufacturing, extrusion, and material properties.

- Conducted extensive testing and analysis to evaluate filament performance and identify areas for improvement.

Frequently Asked Questions (FAQ’s) For Filament Maker

What is the primary role of a Filament Maker?

A Filament Maker is responsible for developing, manufacturing, and testing filaments used in 3D printing. They work with engineers and designers to develop customized filament solutions for specific applications, ensuring the production of high-quality filaments that meet the requirements of the end-user.

What are the key skills required for a Filament Maker?

Key skills for a Filament Maker include extrusion process development, filament design and prototyping, material characterization and testing, polymer processing techniques, filament metrology and quality control, and CAD modeling and simulation.

What are the educational qualifications required to become a Filament Maker?

A Bachelor’s degree in Polymer Science or a related field is typically required to become a Filament Maker.

What are the career prospects for a Filament Maker?

Filament Makers can advance to roles such as Production Manager, Quality Control Manager, or Research and Development Manager. They may also pursue specialized roles in areas such as additive manufacturing or materials science.

What is the average salary for a Filament Maker?

The average salary for a Filament Maker can vary depending on experience, location, and company size. According to Salary.com, the average salary for a Filament Maker in the United States is around $65,000 per year.

What are the major challenges faced by Filament Makers?

Filament Makers face challenges related to developing filaments with the desired properties, such as strength, flexibility, and adhesion. They also need to ensure consistent production of high-quality filaments and troubleshoot any issues that may arise during the manufacturing process.