Are you a seasoned Filling Machine Operator seeking a new career path? Discover our professionally built Filling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

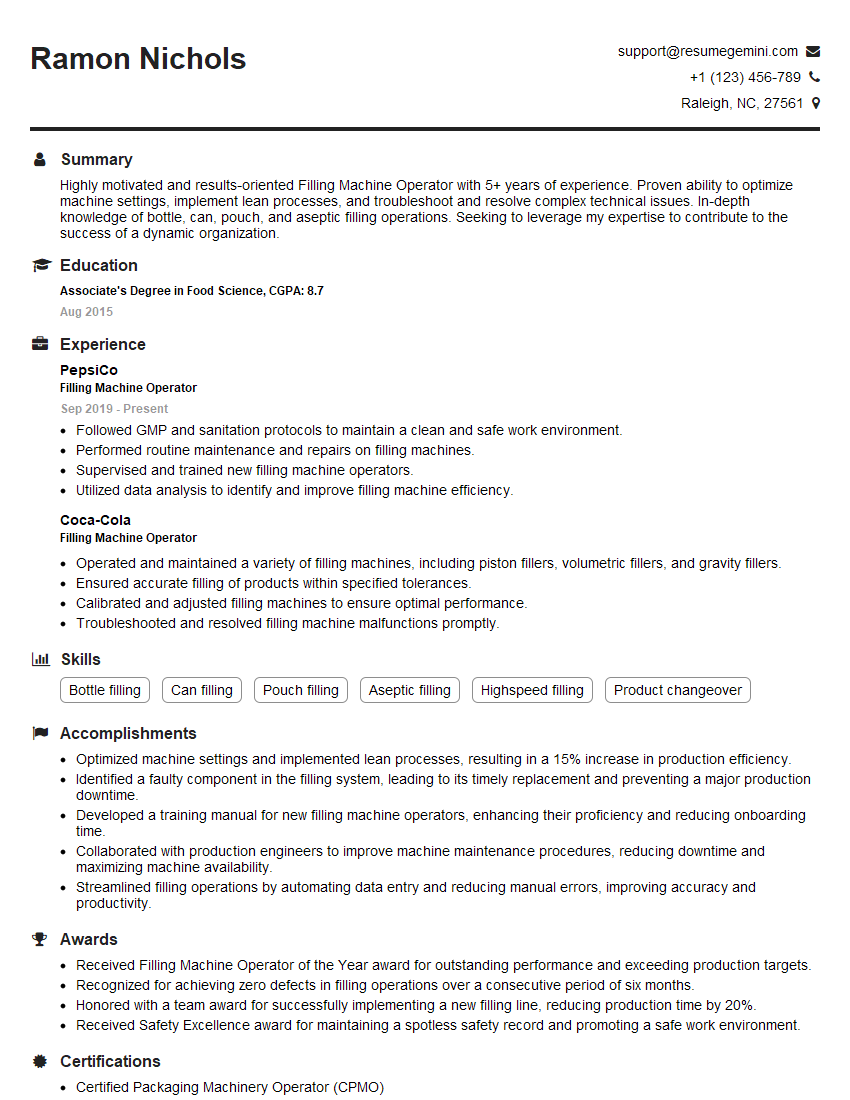

Ramon Nichols

Filling Machine Operator

Summary

Highly motivated and results-oriented Filling Machine Operator with 5+ years of experience. Proven ability to optimize machine settings, implement lean processes, and troubleshoot and resolve complex technical issues. In-depth knowledge of bottle, can, pouch, and aseptic filling operations. Seeking to leverage my expertise to contribute to the success of a dynamic organization.

Education

Associate’s Degree in Food Science

August 2015

Skills

- Bottle filling

- Can filling

- Pouch filling

- Aseptic filling

- Highspeed filling

- Product changeover

Work Experience

Filling Machine Operator

- Followed GMP and sanitation protocols to maintain a clean and safe work environment.

- Performed routine maintenance and repairs on filling machines.

- Supervised and trained new filling machine operators.

- Utilized data analysis to identify and improve filling machine efficiency.

Filling Machine Operator

- Operated and maintained a variety of filling machines, including piston fillers, volumetric fillers, and gravity fillers.

- Ensured accurate filling of products within specified tolerances.

- Calibrated and adjusted filling machines to ensure optimal performance.

- Troubleshooted and resolved filling machine malfunctions promptly.

Accomplishments

- Optimized machine settings and implemented lean processes, resulting in a 15% increase in production efficiency.

- Identified a faulty component in the filling system, leading to its timely replacement and preventing a major production downtime.

- Developed a training manual for new filling machine operators, enhancing their proficiency and reducing onboarding time.

- Collaborated with production engineers to improve machine maintenance procedures, reducing downtime and maximizing machine availability.

- Streamlined filling operations by automating data entry and reducing manual errors, improving accuracy and productivity.

Awards

- Received Filling Machine Operator of the Year award for outstanding performance and exceeding production targets.

- Recognized for achieving zero defects in filling operations over a consecutive period of six months.

- Honored with a team award for successfully implementing a new filling line, reducing production time by 20%.

- Received Safety Excellence award for maintaining a spotless safety record and promoting a safe work environment.

Certificates

- Certified Packaging Machinery Operator (CPMO)

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Food Safety Manager (CFSM)

- Certified HACCP Manager (CHM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Filling Machine Operator

- Highlight your technical proficiency and experience with specific types of filling machines.

- Showcase your problem-solving abilities and success in resolving complex technical issues.

- Quantify your accomplishments by providing specific metrics and results.

- Emphasize your commitment to safety and quality control.

Essential Experience Highlights for a Strong Filling Machine Operator Resume

- Operated and maintained filling machines, ensuring optimal efficiency and minimizing downtime.

- Monitored machine performance, identified potential issues, and took corrective actions to prevent disruptions.

- Inspected products, packaging, and equipment to maintain quality standards.

- Followed safety protocols and maintained a clean and organized work environment.

- Collaborated with production and maintenance teams to resolve technical issues and improve processes.

- Trained new employees on machine operation and maintenance procedures.

- Participated in continuous improvement initiatives to enhance productivity and reduce waste.

Frequently Asked Questions (FAQ’s) For Filling Machine Operator

What are the primary responsibilities of a Filling Machine Operator?

Filling Machine Operators are responsible for operating and maintaining filling machines, monitoring product quality, ensuring safety, and implementing process improvements.

What qualifications are typically required to become a Filling Machine Operator?

Most Filling Machine Operators have a high school diploma or equivalent, with some employers preferring candidates with an associate’s degree in a related field.

What are the key skills required for a successful Filling Machine Operator?

Key skills for Filling Machine Operators include mechanical aptitude, attention to detail, problem-solving abilities, and a strong work ethic.

What is the career outlook for Filling Machine Operators?

The career outlook for Filling Machine Operators is expected to be favorable, with a projected 4% growth in employment over the next decade.

What is the average salary for a Filling Machine Operator?

The average salary for a Filling Machine Operator varies depending on experience, location, and industry, but typically falls between $25,000 and $50,000 per year.

What are the advancement opportunities for Filling Machine Operators?

Filling Machine Operators with experience and additional training may advance to positions such as Production Supervisor, Maintenance Technician, or Quality Control Inspector.

What are the challenges faced by Filling Machine Operators?

Filling Machine Operators may face challenges such as working in a fast-paced and demanding environment, exposure to chemicals and machinery, and the need for ongoing training to stay up-to-date with technological advancements.