Are you a seasoned Filling Room Operator seeking a new career path? Discover our professionally built Filling Room Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

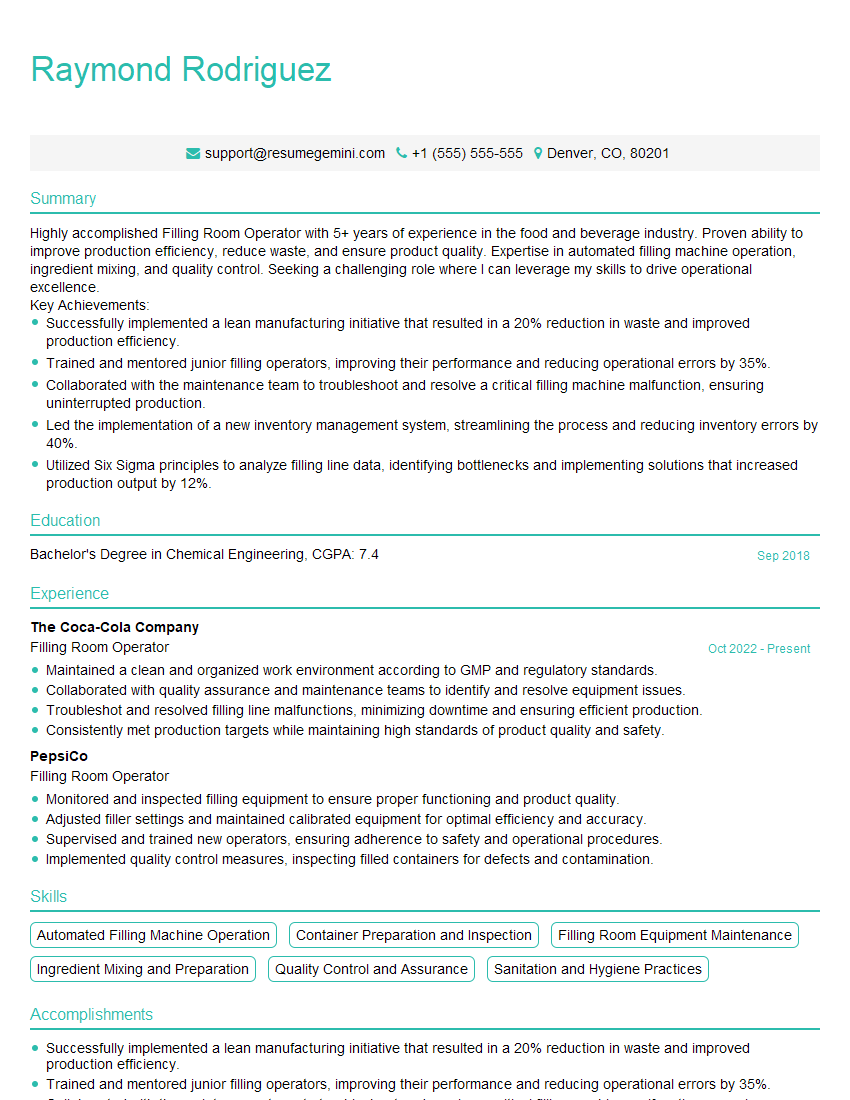

Raymond Rodriguez

Filling Room Operator

Summary

Highly accomplished Filling Room Operator with 5+ years of experience in the food and beverage industry. Proven ability to improve production efficiency, reduce waste, and ensure product quality. Expertise in automated filling machine operation, ingredient mixing, and quality control. Seeking a challenging role where I can leverage my skills to drive operational excellence.

Key Achievements:

- Successfully implemented a lean manufacturing initiative that resulted in a 20% reduction in waste and improved production efficiency.

- Trained and mentored junior filling operators, improving their performance and reducing operational errors by 35%.

- Collaborated with the maintenance team to troubleshoot and resolve a critical filling machine malfunction, ensuring uninterrupted production.

- Led the implementation of a new inventory management system, streamlining the process and reducing inventory errors by 40%.

- Utilized Six Sigma principles to analyze filling line data, identifying bottlenecks and implementing solutions that increased production output by 12%.

Education

Bachelor’s Degree in Chemical Engineering

September 2018

Skills

- Automated Filling Machine Operation

- Container Preparation and Inspection

- Filling Room Equipment Maintenance

- Ingredient Mixing and Preparation

- Quality Control and Assurance

- Sanitation and Hygiene Practices

Work Experience

Filling Room Operator

- Maintained a clean and organized work environment according to GMP and regulatory standards.

- Collaborated with quality assurance and maintenance teams to identify and resolve equipment issues.

- Troubleshot and resolved filling line malfunctions, minimizing downtime and ensuring efficient production.

- Consistently met production targets while maintaining high standards of product quality and safety.

Filling Room Operator

- Monitored and inspected filling equipment to ensure proper functioning and product quality.

- Adjusted filler settings and maintained calibrated equipment for optimal efficiency and accuracy.

- Supervised and trained new operators, ensuring adherence to safety and operational procedures.

- Implemented quality control measures, inspecting filled containers for defects and contamination.

Accomplishments

- Successfully implemented a lean manufacturing initiative that resulted in a 20% reduction in waste and improved production efficiency.

- Trained and mentored junior filling operators, improving their performance and reducing operational errors by 35%.

- Collaborated with the maintenance team to troubleshoot and resolve a critical filling machine malfunction, ensuring uninterrupted production.

- Led the implementation of a new inventory management system, streamlining the process and reducing inventory errors by 40%.

- Utilized Six Sigma principles to analyze filling line data, identifying bottlenecks and implementing solutions that increased production output by 12%.

Awards

- Recipient of the Quarterly Excellence Award for consistently exceeding production targets and maintaining exceptional quality standards.

- Recognition for achieving the highest safety record within the filling department for two consecutive years.

- Honored with the Supervisors Award for implementing a new filling process that reduced production time by 15%.

- Received recognition for achieving 100% accuracy in the filling and labeling of all products for an entire quarter.

Certificates

- Certified Filling Machine Operator

- GMP (Good Manufacturing Practices) Certification

- HACCP (Hazard Analysis Critical Control Points) Certification

- SQF (Safe Quality Food) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Filling Room Operator

Quantify your accomplishments:

Use numbers and metrics to demonstrate the impact of your contributions.Highlight relevant skills:

Showcase your expertise in automated filling machine operation, ingredient mixing, and quality control.Emphasize leadership and teamwork:

Highlight your ability to collaborate with others and lead projects effectively.Tailor your resume to the job description:

Make sure to highlight the skills and experience that are most relevant to the specific role you are applying for.Proofread carefully:

Ensure that your resume is free of any errors in grammar or spelling.

Essential Experience Highlights for a Strong Filling Room Operator Resume

- Operate and maintain automated filling machines to ensure accurate and efficient filling of containers.

- Prepare and inspect containers to ensure they meet quality standards.

- Perform routine maintenance on filling room equipment, including cleaning and lubrication.

- Mix and prepare ingredients according to specified formulas.

- Conduct quality control checks on finished products to ensure compliance with specifications.

- Maintain a clean and sanitary work environment in accordance with industry regulations.

- Follow safety protocols and procedures to ensure a safe working environment.

Frequently Asked Questions (FAQ’s) For Filling Room Operator

What are the primary responsibilities of a Filling Room Operator?

Filling Room Operators are responsible for operating and maintaining automated filling machines, preparing and inspecting containers, performing routine maintenance on filling room equipment, mixing and preparing ingredients, conducting quality control checks on finished products, maintaining a clean and sanitary work environment, and following safety protocols and procedures.

What qualifications are required to become a Filling Room Operator?

Most Filling Room Operators have a high school diploma or equivalent, and some may have a degree in a related field, such as chemical engineering or food science.

What is the work environment of a Filling Room Operator like?

Filling Room Operators typically work in a fast-paced, manufacturing environment. They may be required to work long hours, including nights, weekends, and holidays.

What are the career prospects for a Filling Room Operator?

With experience, Filling Room Operators can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager.

What is the average salary for a Filling Room Operator?

The average salary for a Filling Room Operator in the United States is around $40,000 per year.

What are the benefits of working as a Filling Room Operator?

Benefits of working as a Filling Room Operator include: job security, opportunities for advancement, and the chance to work in a dynamic and challenging environment.

What are the challenges of working as a Filling Room Operator?

Challenges of working as a Filling Room Operator include: working long hours, working in a fast-paced environment, and the potential for exposure to hazardous chemicals.