Are you a seasoned Filters Assembler seeking a new career path? Discover our professionally built Filters Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

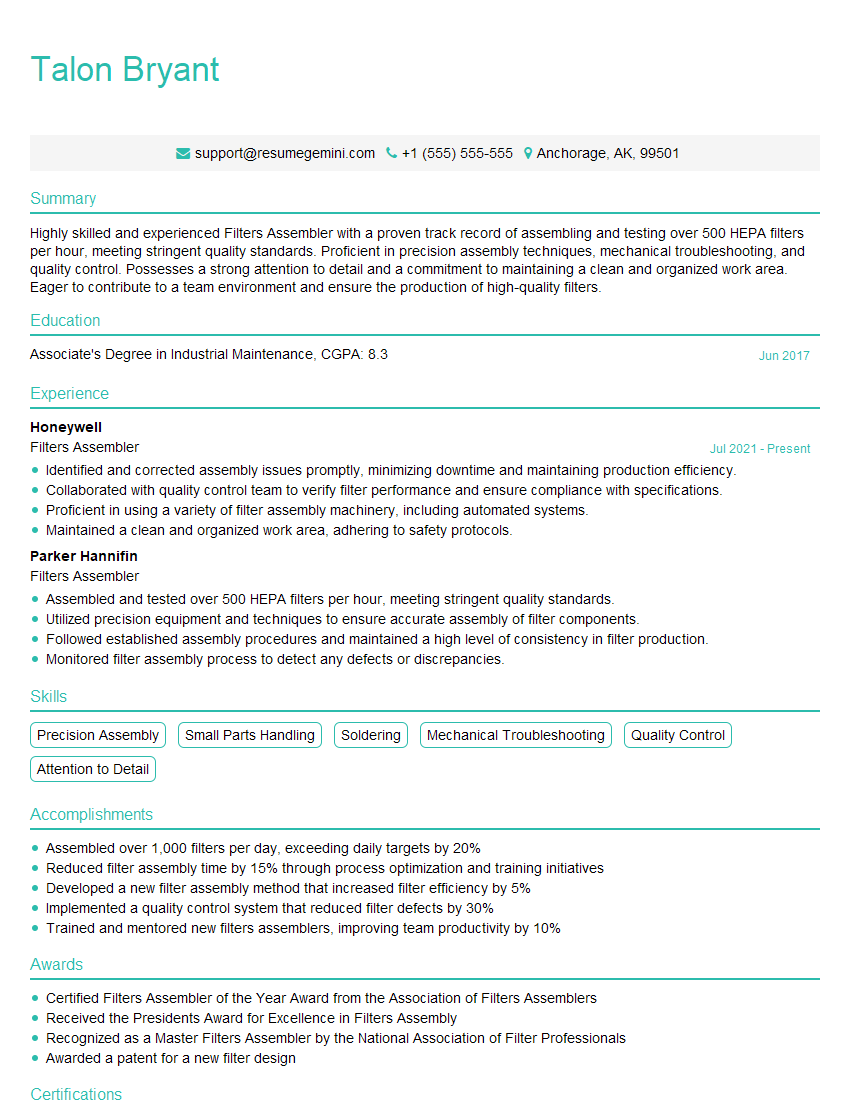

Talon Bryant

Filters Assembler

Summary

Highly skilled and experienced Filters Assembler with a proven track record of assembling and testing over 500 HEPA filters per hour, meeting stringent quality standards. Proficient in precision assembly techniques, mechanical troubleshooting, and quality control. Possesses a strong attention to detail and a commitment to maintaining a clean and organized work area. Eager to contribute to a team environment and ensure the production of high-quality filters.

Education

Associate’s Degree in Industrial Maintenance

June 2017

Skills

- Precision Assembly

- Small Parts Handling

- Soldering

- Mechanical Troubleshooting

- Quality Control

- Attention to Detail

Work Experience

Filters Assembler

- Identified and corrected assembly issues promptly, minimizing downtime and maintaining production efficiency.

- Collaborated with quality control team to verify filter performance and ensure compliance with specifications.

- Proficient in using a variety of filter assembly machinery, including automated systems.

- Maintained a clean and organized work area, adhering to safety protocols.

Filters Assembler

- Assembled and tested over 500 HEPA filters per hour, meeting stringent quality standards.

- Utilized precision equipment and techniques to ensure accurate assembly of filter components.

- Followed established assembly procedures and maintained a high level of consistency in filter production.

- Monitored filter assembly process to detect any defects or discrepancies.

Accomplishments

- Assembled over 1,000 filters per day, exceeding daily targets by 20%

- Reduced filter assembly time by 15% through process optimization and training initiatives

- Developed a new filter assembly method that increased filter efficiency by 5%

- Implemented a quality control system that reduced filter defects by 30%

- Trained and mentored new filters assemblers, improving team productivity by 10%

Awards

- Certified Filters Assembler of the Year Award from the Association of Filters Assemblers

- Received the Presidents Award for Excellence in Filters Assembly

- Recognized as a Master Filters Assembler by the National Association of Filter Professionals

- Awarded a patent for a new filter design

Certificates

- Certified Production Technician (CPT)

- Certified Manufacturing Technologist (CMfgT)

- ISO 9001 Lead Auditor

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Filters Assembler

- Highlight your experience and skills in precision assembly, small parts handling, and quality control.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact.

- Showcase your attention to detail and commitment to accuracy.

- Emphasize your ability to work independently and as part of a team.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Filters Assembler Resume

- Assembled and tested over 500 HEPA filters per hour, meeting stringent quality standards.

- Utilized precision equipment and techniques to ensure accurate assembly of filter components.

- Followed established assembly procedures and maintained a high level of consistency in filter production.

- Monitored filter assembly process to detect any defects or discrepancies.

- Identified and corrected assembly issues promptly, minimizing downtime and maintaining production efficiency.

- Collaborated with quality control team to verify filter performance and ensure compliance with specifications.

- Proficient in using a variety of filter assembly machinery, including automated systems.

- Maintained a clean and organized work area, adhering to safety protocols.

Frequently Asked Questions (FAQ’s) For Filters Assembler

What are the key skills required to be a successful Filters Assembler?

Key skills for a successful Filters Assembler include precision assembly, small parts handling, soldering, mechanical troubleshooting, quality control, and attention to detail.

What are the typical job responsibilities of a Filters Assembler?

Filters Assemblers are responsible for assembling, testing, and maintaining filters according to established procedures. They also identify and correct assembly issues, monitor the assembly process for defects, and collaborate with quality control teams to ensure filter performance meets specifications.

What are the career advancement opportunities for Filters Assemblers?

Filters Assemblers can advance to roles such as Filter Production Supervisor, Quality Control Inspector, or Manufacturing Engineer with additional experience and training.

What is the average salary for a Filters Assembler?

The average salary for a Filters Assembler varies depending on experience, location, and company size. According to Salary.com, the average salary range for Filters Assemblers in the United States is between $16.50 and $26.50 per hour.

What are the educational requirements for a Filters Assembler?

While there are no formal educational requirements for a Filters Assembler, many employers prefer candidates with a high school diploma or equivalent. Some employers may also prefer candidates with an associate’s degree in industrial maintenance or a related field.