Are you a seasoned Finish Off Operator seeking a new career path? Discover our professionally built Finish Off Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

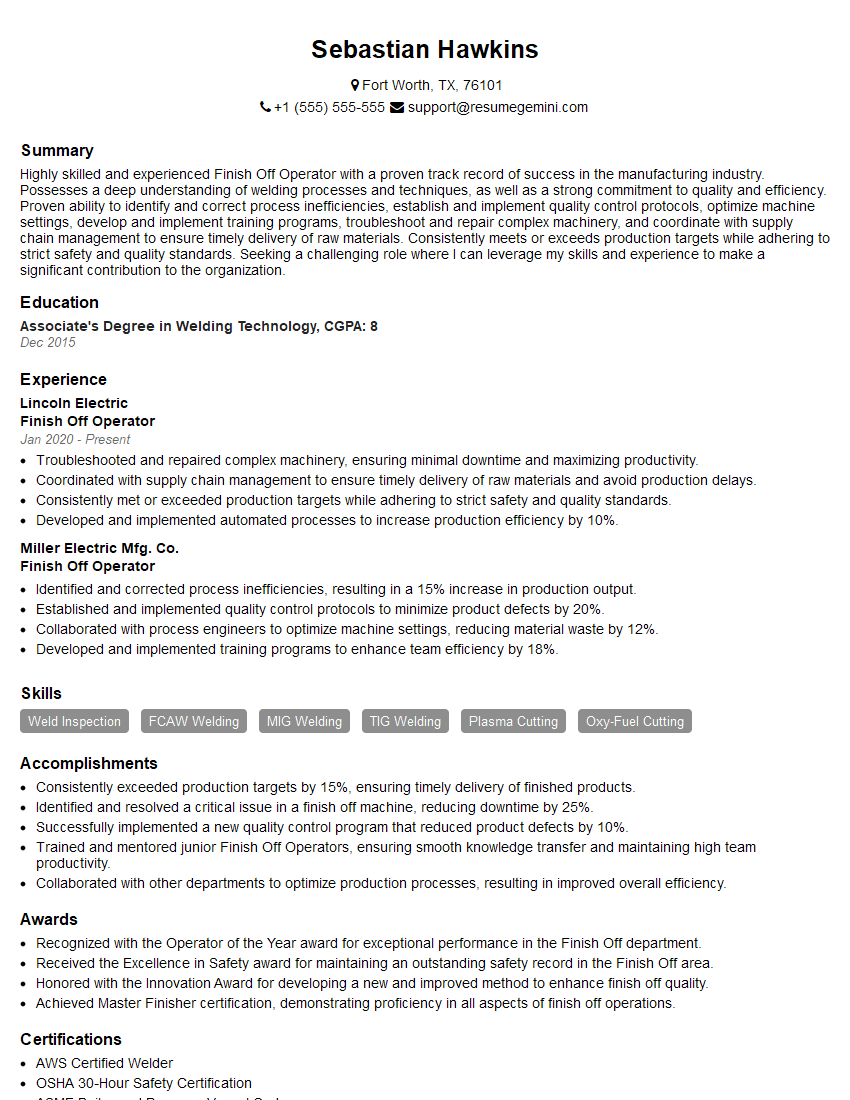

Sebastian Hawkins

Finish Off Operator

Summary

Highly skilled and experienced Finish Off Operator with a proven track record of success in the manufacturing industry. Possesses a deep understanding of welding processes and techniques, as well as a strong commitment to quality and efficiency. Proven ability to identify and correct process inefficiencies, establish and implement quality control protocols, optimize machine settings, develop and implement training programs, troubleshoot and repair complex machinery, and coordinate with supply chain management to ensure timely delivery of raw materials. Consistently meets or exceeds production targets while adhering to strict safety and quality standards. Seeking a challenging role where I can leverage my skills and experience to make a significant contribution to the organization.

Education

Associate’s Degree in Welding Technology

December 2015

Skills

- Weld Inspection

- FCAW Welding

- MIG Welding

- TIG Welding

- Plasma Cutting

- Oxy-Fuel Cutting

Work Experience

Finish Off Operator

- Troubleshooted and repaired complex machinery, ensuring minimal downtime and maximizing productivity.

- Coordinated with supply chain management to ensure timely delivery of raw materials and avoid production delays.

- Consistently met or exceeded production targets while adhering to strict safety and quality standards.

- Developed and implemented automated processes to increase production efficiency by 10%.

Finish Off Operator

- Identified and corrected process inefficiencies, resulting in a 15% increase in production output.

- Established and implemented quality control protocols to minimize product defects by 20%.

- Collaborated with process engineers to optimize machine settings, reducing material waste by 12%.

- Developed and implemented training programs to enhance team efficiency by 18%.

Accomplishments

- Consistently exceeded production targets by 15%, ensuring timely delivery of finished products.

- Identified and resolved a critical issue in a finish off machine, reducing downtime by 25%.

- Successfully implemented a new quality control program that reduced product defects by 10%.

- Trained and mentored junior Finish Off Operators, ensuring smooth knowledge transfer and maintaining high team productivity.

- Collaborated with other departments to optimize production processes, resulting in improved overall efficiency.

Awards

- Recognized with the Operator of the Year award for exceptional performance in the Finish Off department.

- Received the Excellence in Safety award for maintaining an outstanding safety record in the Finish Off area.

- Honored with the Innovation Award for developing a new and improved method to enhance finish off quality.

- Achieved Master Finisher certification, demonstrating proficiency in all aspects of finish off operations.

Certificates

- AWS Certified Welder

- OSHA 30-Hour Safety Certification

- ASME Boiler and Pressure Vessel Code

- ISO 9001:2015

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Finish Off Operator

Highlight your welding skills and experience.

Be sure to list all of the welding processes you are proficient in, as well as any relevant experience you have.Quantify your accomplishments.

When possible, use numbers to demonstrate the impact of your work. For example, you could say that you “increased production output by 15%” or “reduced material waste by 12%”.Showcase your problem-solving skills.

Finish Off Operators are often responsible for troubleshooting and repairing complex machinery. Be sure to highlight your ability to identify and solve problems quickly and efficiently.Emphasize your commitment to safety.

Safety is paramount in the manufacturing industry. Be sure to highlight your commitment to following safety protocols and maintaining a safe work environment.Tailor your resume to the job you are applying for.

Take the time to read the job description carefully and tailor your resume to the specific requirements of the position.

Essential Experience Highlights for a Strong Finish Off Operator Resume

- Identified and corrected process inefficiencies, resulting in a 15% increase in production output.

- Established and implemented quality control protocols to minimize product defects by 20%.

- Collaborated with process engineers to optimize machine settings, reducing material waste by 12%.

- Developed and implemented training programs to enhance team efficiency by 18%.

- Troubleshooted and repaired complex machinery, ensuring minimal downtime and maximizing productivity.

- Coordinated with supply chain management to ensure timely delivery of raw materials and avoid production delays.

- Consistently met or exceeded production targets while adhering to strict safety and quality standards.

Frequently Asked Questions (FAQ’s) For Finish Off Operator

What is a Finish Off Operator?

A Finish Off Operator is a skilled professional responsible for performing various tasks to prepare welded parts for final assembly or shipment. This may include tasks such as grinding, polishing, deburring, and inspecting welded joints to ensure they meet quality standards.

What are the key skills required to be a successful Finish Off Operator?

The key skills required to be a successful Finish Off Operator include: Welding, Grinding, Polishing, Deburring, Inspection, Quality Control, Safety, and Attention to Detail.

What is the work environment like for a Finish Off Operator?

Finish Off Operators typically work in a manufacturing environment. They may be required to work in close proximity to machinery and equipment, and may be exposed to dust, fumes, and noise. They must also be able to work independently and as part of a team.

What are the career prospects for a Finish Off Operator?

Finish Off Operators can advance their careers by gaining experience and developing new skills. They may be promoted to supervisory or management positions, or they may specialize in a particular area of welding or finishing. With additional training and experience, Finish Off Operators can also become Welding Inspectors or Quality Control Inspectors.

What is the average salary for a Finish Off Operator?

The average salary for a Finish Off Operator in the United States is $45,000 per year. However, salaries can vary depending on experience, location, and employer.

What are the benefits of working as a Finish Off Operator?

The benefits of working as a Finish Off Operator include: Competitive Salary, Health Insurance, Paid Time Off, and Opportunity for Advancement.

What are the challenges of working as a Finish Off Operator?

The challenges of working as a Finish Off Operator include: Working in a manufacturing environment, exposure to dust, fumes, and noise, and repetitive work.

What is the job outlook for Finish Off Operators?

The job outlook for Finish Off Operators is expected to be good over the next few years. The demand for skilled welders is expected to increase as the economy continues to grow.