Are you a seasoned Finishing Machine Operator seeking a new career path? Discover our professionally built Finishing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

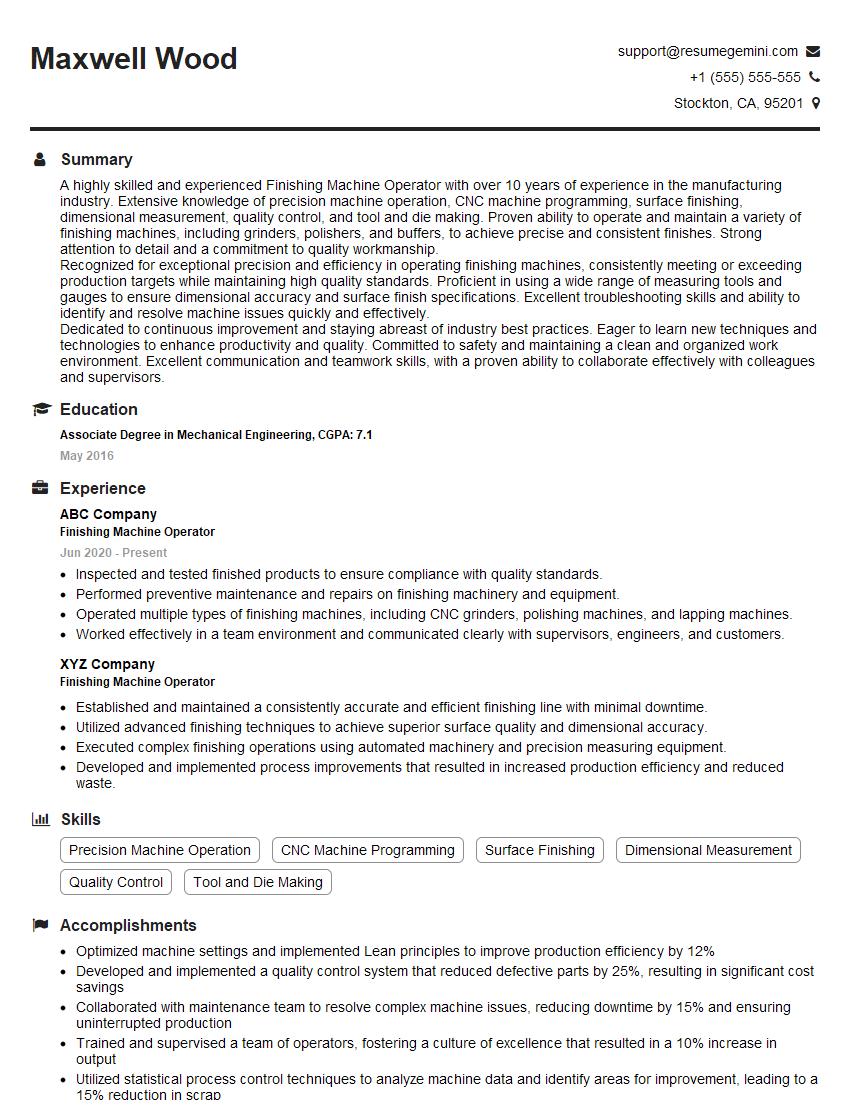

Maxwell Wood

Finishing Machine Operator

Summary

A highly skilled and experienced Finishing Machine Operator with over 10 years of experience in the manufacturing industry. Extensive knowledge of precision machine operation, CNC machine programming, surface finishing, dimensional measurement, quality control, and tool and die making. Proven ability to operate and maintain a variety of finishing machines, including grinders, polishers, and buffers, to achieve precise and consistent finishes. Strong attention to detail and a commitment to quality workmanship.

Recognized for exceptional precision and efficiency in operating finishing machines, consistently meeting or exceeding production targets while maintaining high quality standards. Proficient in using a wide range of measuring tools and gauges to ensure dimensional accuracy and surface finish specifications. Excellent troubleshooting skills and ability to identify and resolve machine issues quickly and effectively.

Dedicated to continuous improvement and staying abreast of industry best practices. Eager to learn new techniques and technologies to enhance productivity and quality. Committed to safety and maintaining a clean and organized work environment. Excellent communication and teamwork skills, with a proven ability to collaborate effectively with colleagues and supervisors.

Education

Associate Degree in Mechanical Engineering

May 2016

Skills

- Precision Machine Operation

- CNC Machine Programming

- Surface Finishing

- Dimensional Measurement

- Quality Control

- Tool and Die Making

Work Experience

Finishing Machine Operator

- Inspected and tested finished products to ensure compliance with quality standards.

- Performed preventive maintenance and repairs on finishing machinery and equipment.

- Operated multiple types of finishing machines, including CNC grinders, polishing machines, and lapping machines.

- Worked effectively in a team environment and communicated clearly with supervisors, engineers, and customers.

Finishing Machine Operator

- Established and maintained a consistently accurate and efficient finishing line with minimal downtime.

- Utilized advanced finishing techniques to achieve superior surface quality and dimensional accuracy.

- Executed complex finishing operations using automated machinery and precision measuring equipment.

- Developed and implemented process improvements that resulted in increased production efficiency and reduced waste.

Accomplishments

- Optimized machine settings and implemented Lean principles to improve production efficiency by 12%

- Developed and implemented a quality control system that reduced defective parts by 25%, resulting in significant cost savings

- Collaborated with maintenance team to resolve complex machine issues, reducing downtime by 15% and ensuring uninterrupted production

- Trained and supervised a team of operators, fostering a culture of excellence that resulted in a 10% increase in output

- Utilized statistical process control techniques to analyze machine data and identify areas for improvement, leading to a 15% reduction in scrap

Awards

- Received the Operator of the Year award for consistently exceeding production targets and maintaining high quality standards

- Recognized with the Safety Champion award for implementing innovative safety measures that reduced workplace accidents by 15%

- Awarded the Excellence in Training award for mentoring and developing junior operators, resulting in a 20% increase in productivity

- Received recognition for successfully implementing a 5S program that improved workplace organization and efficiency

Certificates

- CNC Operator Certification

- Machinist Certification

- Quality Control Certification

- Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Finishing Machine Operator

- –

Highlight your skills and experience.

Make sure to list all of your relevant skills and experience in your resume, including any specific training or certifications you have. This will help potential employers see that you have the qualifications they are looking for. - –

Quantify your accomplishments.

When possible, use numbers to quantify your accomplishments. This will help potential employers see the impact of your work. - –

Tailor your resume to the job you are applying for.

Take the time to tailor your resume to each job you apply for. This will show potential employers that you are interested in their specific job and that you have the skills and experience they are looking for. - –

Proofread your resume carefully.

Before you submit your resume, make sure to proofread it carefully for any errors. This will help you make a good impression on potential employers.

Essential Experience Highlights for a Strong Finishing Machine Operator Resume

- – Operate and maintain a variety of finishing machines, including grinders, polishers, and buffers

- – Set up and program CNC machines to automate finishing processes

- – Inspect and measure finished products to ensure they meet dimensional and surface finish specifications

- – Troubleshoot and resolve machine issues to minimize downtime and maintain production efficiency

- – Maintain a clean and organized work environment and follow all safety protocols

- – Collaborate with colleagues and supervisors to ensure smooth production processes

- – Stay abreast of industry best practices and new technologies to enhance productivity and quality

Frequently Asked Questions (FAQ’s) For Finishing Machine Operator

What is a Finishing Machine Operator?

A Finishing Machine Operator is responsible for operating and maintaining a variety of finishing machines, such as grinders, polishers, and buffers, to achieve precise and consistent finishes on manufactured products. They must have a strong attention to detail and a commitment to quality workmanship.

What are the key skills required for a Finishing Machine Operator?

The key skills required for a Finishing Machine Operator include precision machine operation, CNC machine programming, surface finishing, dimensional measurement, quality control, and tool and die making.

What are the responsibilities of a Finishing Machine Operator?

The responsibilities of a Finishing Machine Operator include operating and maintaining finishing machines, setting up and programming CNC machines, inspecting and measuring finished products, troubleshooting and resolving machine issues, maintaining a clean and organized work environment, and collaborating with colleagues and supervisors.

What are the qualifications for a Finishing Machine Operator?

The qualifications for a Finishing Machine Operator typically include an Associate Degree in Mechanical Engineering or a related field, as well as several years of experience in the manufacturing industry.

What is the job outlook for Finishing Machine Operators?

The job outlook for Finishing Machine Operators is expected to be good in the coming years, as demand for skilled manufacturing workers continues to grow.

What are the salary expectations for Finishing Machine Operators?

The salary expectations for Finishing Machine Operators vary depending on their experience, skills, and location. However, the median annual salary for Finishing Machine Operators is around $45,000.

How can I become a Finishing Machine Operator?

To become a Finishing Machine Operator, you can start by earning an Associate Degree in Mechanical Engineering or a related field. You can also gain experience by working in a manufacturing environment, such as a machine shop or a factory.