Are you a seasoned Firepot Operator and Tender seeking a new career path? Discover our professionally built Firepot Operator and Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

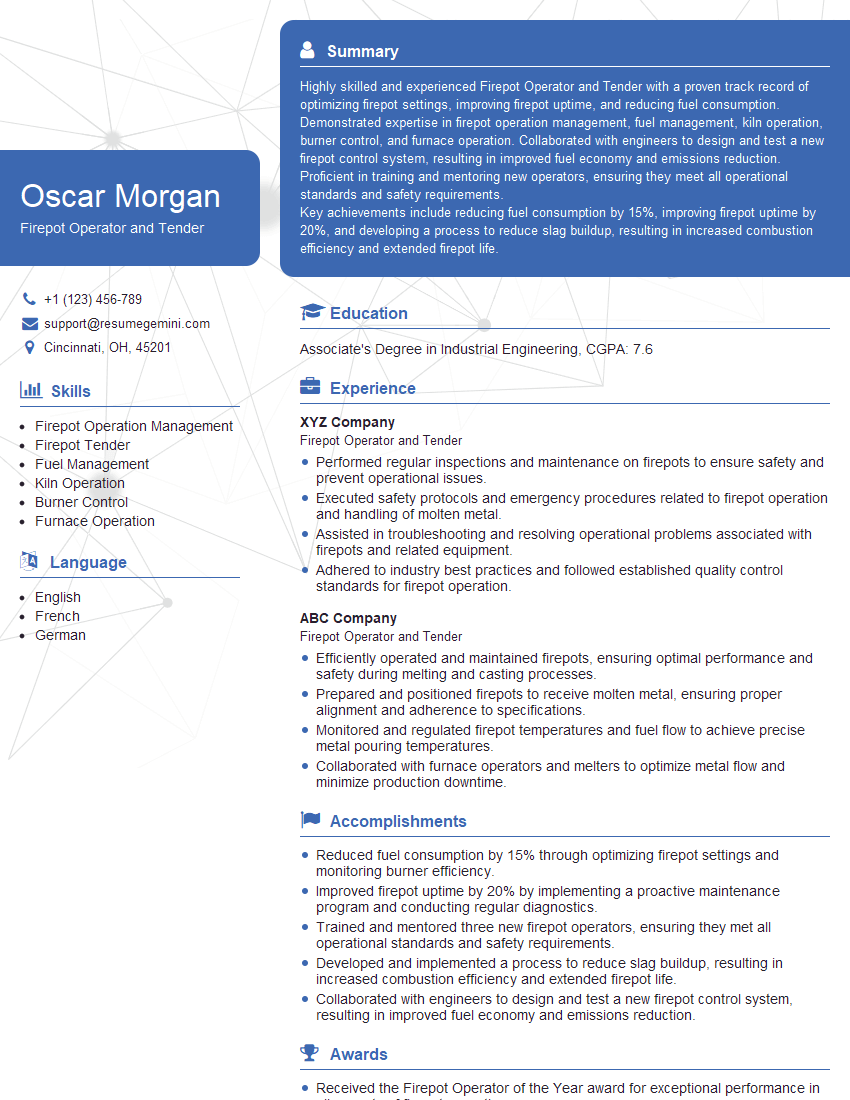

Oscar Morgan

Firepot Operator and Tender

Summary

Highly skilled and experienced Firepot Operator and Tender with a proven track record of optimizing firepot settings, improving firepot uptime, and reducing fuel consumption. Demonstrated expertise in firepot operation management, fuel management, kiln operation, burner control, and furnace operation. Collaborated with engineers to design and test a new firepot control system, resulting in improved fuel economy and emissions reduction. Proficient in training and mentoring new operators, ensuring they meet all operational standards and safety requirements.

Key achievements include reducing fuel consumption by 15%, improving firepot uptime by 20%, and developing a process to reduce slag buildup, resulting in increased combustion efficiency and extended firepot life.

Education

Associate’s Degree in Industrial Engineering

July 2018

Skills

- Firepot Operation Management

- Firepot Tender

- Fuel Management

- Kiln Operation

- Burner Control

- Furnace Operation

Work Experience

Firepot Operator and Tender

- Performed regular inspections and maintenance on firepots to ensure safety and prevent operational issues.

- Executed safety protocols and emergency procedures related to firepot operation and handling of molten metal.

- Assisted in troubleshooting and resolving operational problems associated with firepots and related equipment.

- Adhered to industry best practices and followed established quality control standards for firepot operation.

Firepot Operator and Tender

- Efficiently operated and maintained firepots, ensuring optimal performance and safety during melting and casting processes.

- Prepared and positioned firepots to receive molten metal, ensuring proper alignment and adherence to specifications.

- Monitored and regulated firepot temperatures and fuel flow to achieve precise metal pouring temperatures.

- Collaborated with furnace operators and melters to optimize metal flow and minimize production downtime.

Accomplishments

- Reduced fuel consumption by 15% through optimizing firepot settings and monitoring burner efficiency.

- Improved firepot uptime by 20% by implementing a proactive maintenance program and conducting regular diagnostics.

- Trained and mentored three new firepot operators, ensuring they met all operational standards and safety requirements.

- Developed and implemented a process to reduce slag buildup, resulting in increased combustion efficiency and extended firepot life.

- Collaborated with engineers to design and test a new firepot control system, resulting in improved fuel economy and emissions reduction.

Awards

- Received the Firepot Operator of the Year award for exceptional performance in all aspects of firepot operations.

- Recognized with a Safety Excellence Award for implementing innovative safety protocols that significantly reduced workplace hazards.

- Honored with a Certificate of Excellence for outstanding contributions to maximizing firepot productivity.

- Received a Presidents Club Award for exceeding performance targets and consistently delivering exceptional results.

Certificates

- Firepot Operator Certification

- Firepot Tender Certification

- Fuel Management Certification

- Kiln Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Firepot Operator and Tender

- Highlight your expertise in firepot operation management, fuel management, and combustion optimization.

- Quantify your accomplishments with specific metrics, such as percentage improvements in fuel consumption and firepot uptime.

- Showcase your ability to troubleshoot and resolve firepot issues, ensuring smooth and efficient operations.

- Emphasize your teamwork and collaboration skills, especially in working with engineers to improve firepot control systems.

- Demonstrate your commitment to safety and adherence to industry regulations and best practices.

Essential Experience Highlights for a Strong Firepot Operator and Tender Resume

- Operate and monitor firepots to ensure efficient combustion and fuel optimization.

- Conduct regular diagnostics and implement a proactive maintenance program to minimize downtime and maximize firepot lifespan.

- Manage fuel supply, ensuring optimal fuel-to-air ratios for efficient combustion.

- Collaborate with kiln operators to optimize kiln performance and maintain desired temperatures.

- Control burners and adjust firepot settings to achieve desired heat levels and process requirements.

- Monitor and maintain furnace operations to ensure safe and efficient functioning.

Frequently Asked Questions (FAQ’s) For Firepot Operator and Tender

What are the primary responsibilities of a Firepot Operator and Tender?

Firepot Operators and Tenders are responsible for operating and maintaining firepots, managing fuel supply, controlling burners, and ensuring efficient combustion processes in industrial settings, such as kilns and furnaces.

What skills are essential for a Firepot Operator and Tender?

Essential skills include knowledge of firepot operation and maintenance, fuel management, burner control, and kiln or furnace operations. Strong troubleshooting abilities, attention to detail, and adherence to safety protocols are also crucial.

What industries employ Firepot Operators and Tenders?

Firepot Operators and Tenders are primarily employed in industries that utilize kilns and furnaces, such as ceramics, glass manufacturing, metalworking, and power generation.

What is the career growth potential for a Firepot Operator and Tender?

With experience and additional training, Firepot Operators and Tenders can advance to supervisory roles, such as Kiln Operator or Furnace Operator. They may also specialize in specific areas, such as combustion optimization or fuel management.

What are the safety considerations for a Firepot Operator and Tender?

Firepot Operators and Tenders work in high-temperature environments and must adhere to strict safety protocols. They wear protective gear, follow proper lockout/tagout procedures, and are trained in emergency response measures.

What is the work environment like for a Firepot Operator and Tender?

Firepot Operators and Tenders typically work in industrial settings, such as factories or power plants. The work can be physically demanding and requires attention to detail and adherence to safety protocols.

What are the educational requirements to become a Firepot Operator and Tender?

While formal education requirements may vary, many employers prefer candidates with an Associate’s Degree in Industrial Engineering or a related field.

What certifications are beneficial for a Firepot Operator and Tender?

Industry-recognized certifications, such as those offered by the National Institute for Certification in Engineering Technologies (NICET), can enhance credibility and demonstrate proficiency in specific areas of firepot operation and maintenance.