Are you a seasoned Flaker Operator seeking a new career path? Discover our professionally built Flaker Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

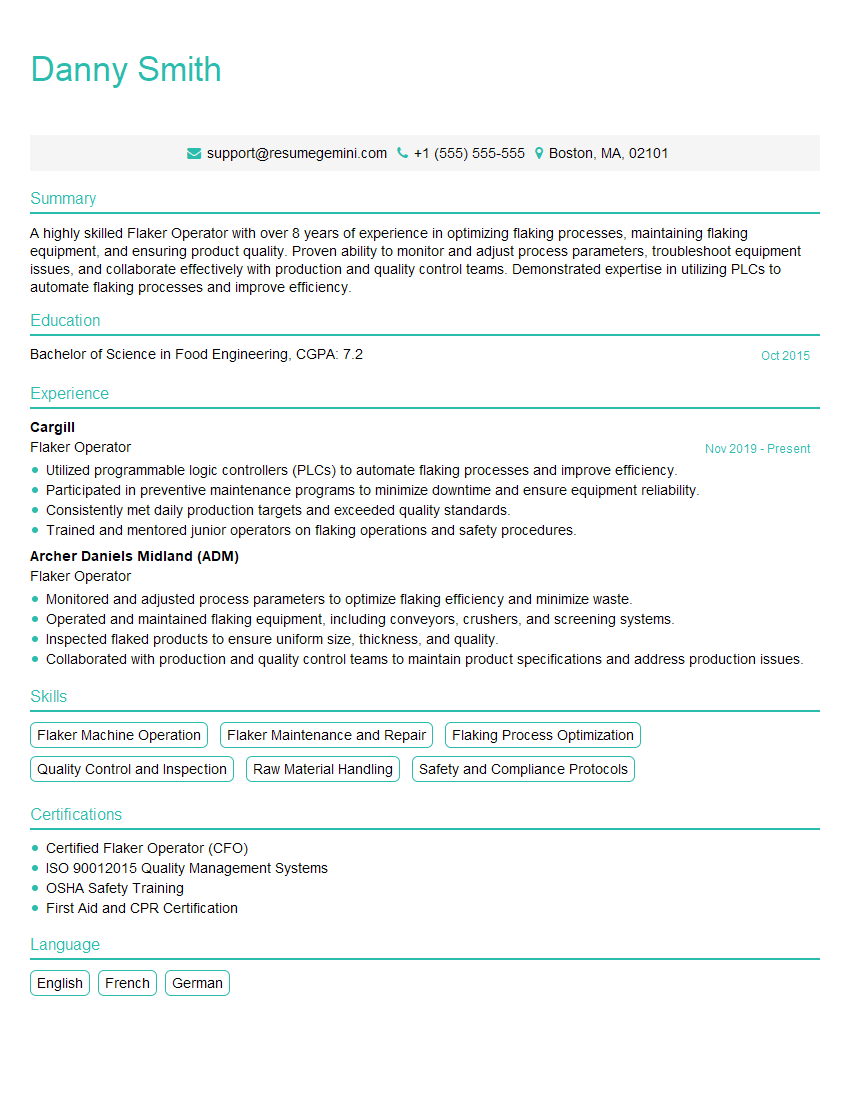

Danny Smith

Flaker Operator

Summary

A highly skilled Flaker Operator with over 8 years of experience in optimizing flaking processes, maintaining flaking equipment, and ensuring product quality. Proven ability to monitor and adjust process parameters, troubleshoot equipment issues, and collaborate effectively with production and quality control teams. Demonstrated expertise in utilizing PLCs to automate flaking processes and improve efficiency.

Education

Bachelor of Science in Food Engineering

October 2015

Skills

- Flaker Machine Operation

- Flaker Maintenance and Repair

- Flaking Process Optimization

- Quality Control and Inspection

- Raw Material Handling

- Safety and Compliance Protocols

Work Experience

Flaker Operator

- Utilized programmable logic controllers (PLCs) to automate flaking processes and improve efficiency.

- Participated in preventive maintenance programs to minimize downtime and ensure equipment reliability.

- Consistently met daily production targets and exceeded quality standards.

- Trained and mentored junior operators on flaking operations and safety procedures.

Flaker Operator

- Monitored and adjusted process parameters to optimize flaking efficiency and minimize waste.

- Operated and maintained flaking equipment, including conveyors, crushers, and screening systems.

- Inspected flaked products to ensure uniform size, thickness, and quality.

- Collaborated with production and quality control teams to maintain product specifications and address production issues.

Certificates

- Certified Flaker Operator (CFO)

- ISO 90012015 Quality Management Systems

- OSHA Safety Training

- First Aid and CPR Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flaker Operator

- Highlight your expertise in optimizing flaking processes and minimizing waste, quantifying the results you achieved.

- Demonstrate your proficiency in operating and maintaining flaking equipment, including troubleshooting and resolving complex issues.

- Emphasize your ability to collaborate effectively with production and quality control teams, ensuring seamless communication and efficient problem-solving.

- Showcase your experience in utilizing PLCs to automate flaking processes, highlighting the improvements you implemented and the benefits gained.

- Include examples of your involvement in preventive maintenance programs, demonstrating your commitment to equipment reliability and minimizing downtime.

Essential Experience Highlights for a Strong Flaker Operator Resume

- Monitored and adjusted process parameters (temperature, pressure, feed rate) to optimize flaking efficiency and minimize waste.

- Operated and maintained flaking equipment, including conveyors, crushers, and screening systems, to ensure smooth operation and adherence to safety protocols.

- Inspected flaked products to ensure uniform size, thickness, and quality, and took corrective actions as needed to maintain product specifications.

- Collaborated with production and quality control teams to maintain product specifications and address production issues, providing valuable insights and support.

- Utilized programmable logic controllers (PLCs) to automate flaking processes and improve efficiency, reducing manual intervention and enhancing overall productivity.

- Participated in preventive maintenance programs to minimize downtime, identify potential issues, and ensure equipment reliability.

- Trained and mentored junior operators on flaking operations and safety procedures, fostering knowledge transfer and ensuring operational continuity.

Frequently Asked Questions (FAQ’s) For Flaker Operator

What are the key skills required to be a successful Flaker Operator?

Key skills for Flaker Operators include flaker machine operation, flaker maintenance and repair, flaking process optimization, quality control and inspection, raw material handling, and adherence to safety and compliance protocols.

What are the career advancement opportunities for Flaker Operators?

Flaker Operators can advance their careers by becoming Shift Supervisors, Production Supervisors, or Quality Control Managers. With experience and additional training, they can also move into roles in process engineering or plant management.

What are the typical working conditions for Flaker Operators?

Flaker Operators typically work in production environments, often in close proximity to heavy machinery and noise. They may work shifts, including nights, weekends, and holidays, to meet production demands.

What are the safety protocols that Flaker Operators must follow?

Flaker Operators must adhere to strict safety protocols, including wearing appropriate personal protective equipment (PPE), following lockout/tagout procedures, and being aware of potential hazards such as moving machinery and electrical equipment.

What is the average salary for Flaker Operators?

The average salary for Flaker Operators varies depending on experience, location, and industry. According to Salary.com, the average annual salary for Flaker Operators in the United States is around $50,000.

What are the job prospects for Flaker Operators?

The job outlook for Flaker Operators is expected to be stable in the coming years, as the demand for processed food products continues to grow. Flaker Operators with strong skills and experience will have the best job prospects.

What are some tips for writing a standout Flaker Operator resume?

To write a standout Flaker Operator resume, highlight your skills and experience in operating and maintaining flaking equipment, optimizing flaking processes, and ensuring product quality. Quantify your accomplishments whenever possible, and use action verbs to describe your responsibilities.

What are some common interview questions for Flaker Operators?

Common interview questions for Flaker Operators include questions about their experience operating and maintaining flaking equipment, their knowledge of flaking processes, and their ability to work in a team environment. They may also be asked about their safety protocols and their commitment to quality.