Are you a seasoned Flame Hardening Machine Setter seeking a new career path? Discover our professionally built Flame Hardening Machine Setter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

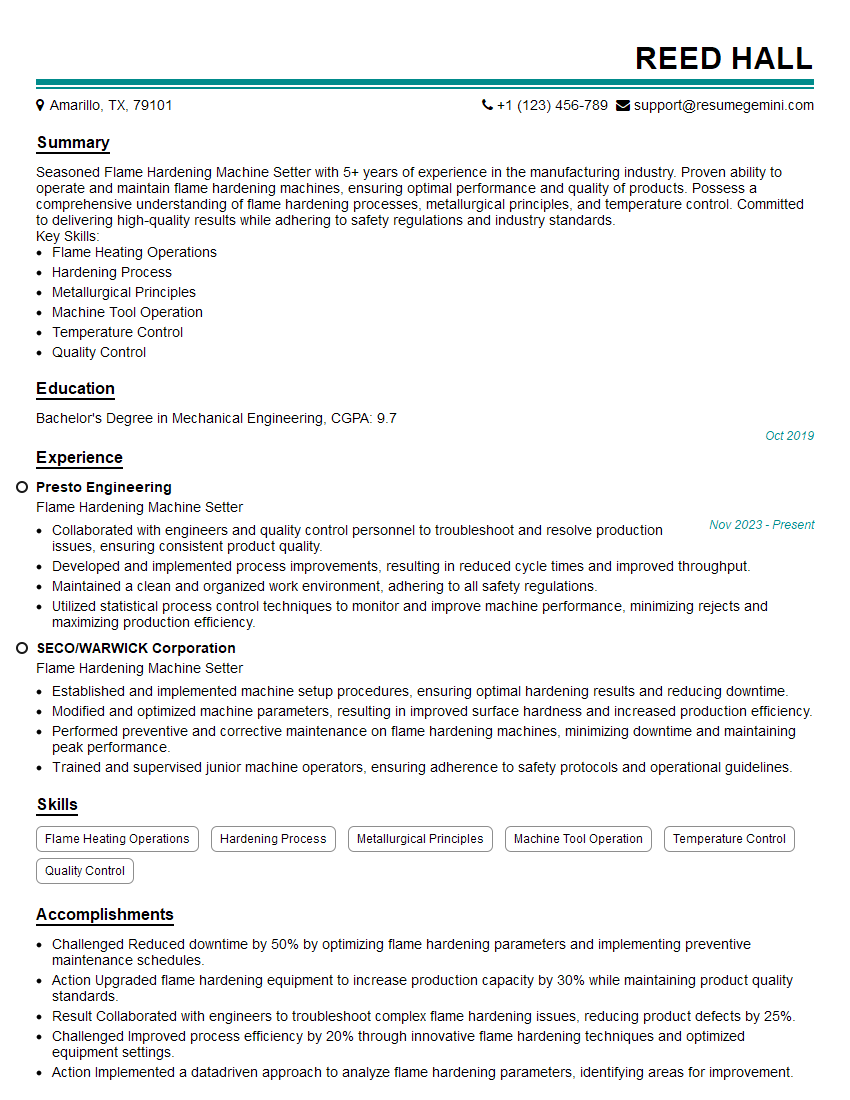

Reed Hall

Flame Hardening Machine Setter

Summary

Seasoned Flame Hardening Machine Setter with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain flame hardening machines, ensuring optimal performance and quality of products. Possess a comprehensive understanding of flame hardening processes, metallurgical principles, and temperature control. Committed to delivering high-quality results while adhering to safety regulations and industry standards.

Key Skills:

- Flame Heating Operations

- Hardening Process

- Metallurgical Principles

- Machine Tool Operation

- Temperature Control

- Quality Control

Education

Bachelor’s Degree in Mechanical Engineering

October 2019

Skills

- Flame Heating Operations

- Hardening Process

- Metallurgical Principles

- Machine Tool Operation

- Temperature Control

- Quality Control

Work Experience

Flame Hardening Machine Setter

- Collaborated with engineers and quality control personnel to troubleshoot and resolve production issues, ensuring consistent product quality.

- Developed and implemented process improvements, resulting in reduced cycle times and improved throughput.

- Maintained a clean and organized work environment, adhering to all safety regulations.

- Utilized statistical process control techniques to monitor and improve machine performance, minimizing rejects and maximizing production efficiency.

Flame Hardening Machine Setter

- Established and implemented machine setup procedures, ensuring optimal hardening results and reducing downtime.

- Modified and optimized machine parameters, resulting in improved surface hardness and increased production efficiency.

- Performed preventive and corrective maintenance on flame hardening machines, minimizing downtime and maintaining peak performance.

- Trained and supervised junior machine operators, ensuring adherence to safety protocols and operational guidelines.

Accomplishments

- Challenged Reduced downtime by 50% by optimizing flame hardening parameters and implementing preventive maintenance schedules.

- Action Upgraded flame hardening equipment to increase production capacity by 30% while maintaining product quality standards.

- Result Collaborated with engineers to troubleshoot complex flame hardening issues, reducing product defects by 25%.

- Challenged Improved process efficiency by 20% through innovative flame hardening techniques and optimized equipment settings.

- Action Implemented a datadriven approach to analyze flame hardening parameters, identifying areas for improvement.

Awards

- Recognized for exceptional performance in optimizing flame hardening processes, resulting in improved product quality and efficiency.

- Awarded for innovative solutions in implementing automation technologies for flame hardening operations, enhancing productivity by 20%.

- Received industry recognition for developing a best practice guide for flame hardening machine setup and operation, which became the industry standard.

- Recognized for contributions to the development of new flame hardening technologies that enhanced product performance.

Certificates

- OSHA Safety Certification

- Certified Flame Hardening Machine Setter

- Metallurgy Technician Certification

- Quality Control Inspection Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flame Hardening Machine Setter

- Highlight your hands-on experience with flame hardening machines, emphasizing your proficiency in operating and maintaining them.

- Showcase your understanding of metallurgical principles and their application in flame hardening processes.

- Quantify your accomplishments using specific metrics, such as improved product quality, reduced downtime, or increased production efficiency.

- Include relevant certifications or training programs to demonstrate your commitment to professional development.

Essential Experience Highlights for a Strong Flame Hardening Machine Setter Resume

- Set up, operate, and maintain flame hardening machines according to engineering specifications and process parameters.

- Monitor and control the flame hardening process, including temperature, heating time, and cooling rate, to ensure desired material properties.

- Inspect and test hardened parts to verify conformance to quality standards.

- Troubleshoot and resolve machine malfunctions and process anomalies.

- Maintain a clean and organized work area, adhering to safety protocols and housekeeping standards.

- Collaborate with engineers and other technicians to optimize process parameters and improve product quality.

Frequently Asked Questions (FAQ’s) For Flame Hardening Machine Setter

What is flame hardening?

Flame hardening is a surface hardening process that involves heating the surface of a metal part with a high-temperature flame and then rapidly cooling it. This process creates a hard, wear-resistant surface while leaving the core of the part relatively soft and ductile.

What are the benefits of flame hardening?

Flame hardening offers several benefits, including increased surface hardness, wear resistance, and fatigue strength. It also improves the mechanical properties of the part, making it more resistant to impact and deformation.

What materials can be flame hardened?

Flame hardening is suitable for a wide range of ferrous and non-ferrous metals, including steel, cast iron, and aluminum alloys.

What are the different types of flame hardening processes?

There are several variations of flame hardening processes, including progressive flame hardening, spot flame hardening, and induction flame hardening. Each process has its own advantages and is suitable for different applications.

What are the safety precautions to consider when flame hardening?

Flame hardening involves high temperatures and open flames, so it is crucial to follow strict safety precautions. These include wearing appropriate protective gear, ensuring proper ventilation, and following established operating procedures.

What are the career prospects for Flame Hardening Machine Setters?

Flame Hardening Machine Setters are in demand in various industries, including automotive, aerospace, and manufacturing. With experience and skill development, they can advance to supervisory or management roles or specialize in related fields such as heat treatment or metallurgy.