Are you a seasoned Flange Machine Operator seeking a new career path? Discover our professionally built Flange Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

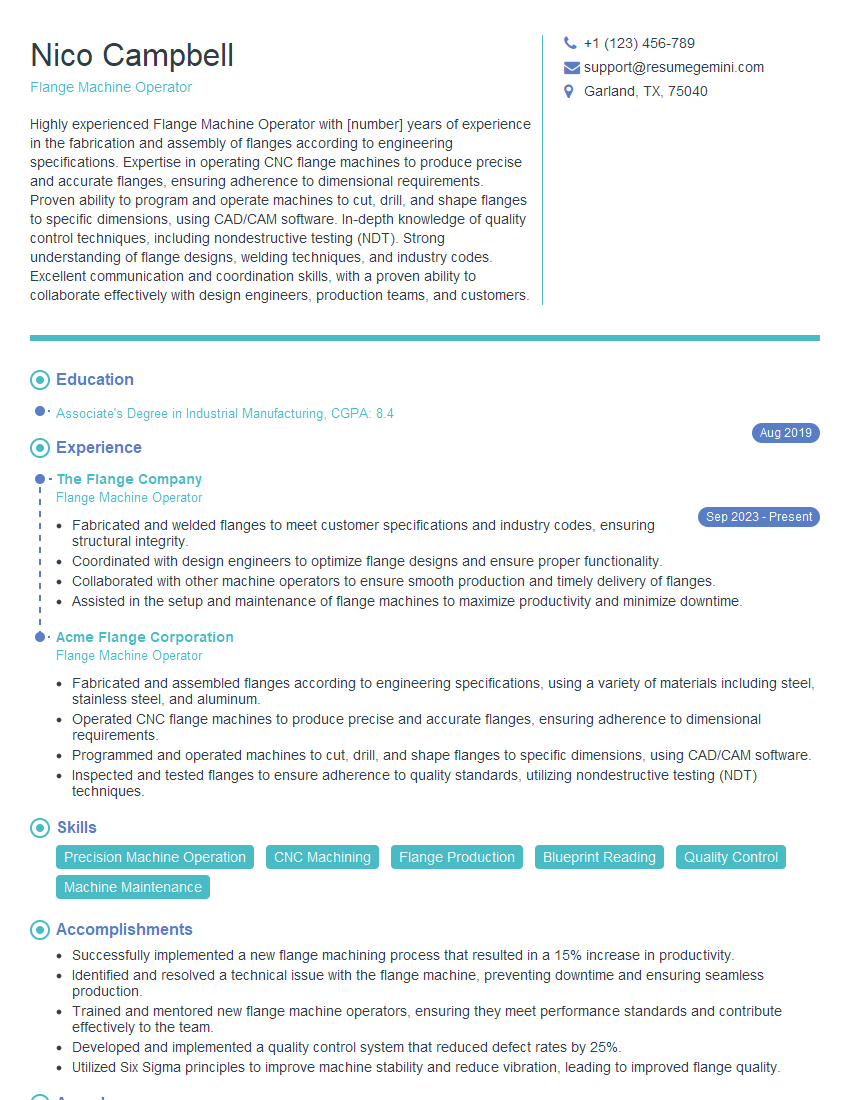

Nico Campbell

Flange Machine Operator

Summary

Highly experienced Flange Machine Operator with [number] years of experience in the fabrication and assembly of flanges according to engineering specifications. Expertise in operating CNC flange machines to produce precise and accurate flanges, ensuring adherence to dimensional requirements. Proven ability to program and operate machines to cut, drill, and shape flanges to specific dimensions, using CAD/CAM software. In-depth knowledge of quality control techniques, including nondestructive testing (NDT). Strong understanding of flange designs, welding techniques, and industry codes. Excellent communication and coordination skills, with a proven ability to collaborate effectively with design engineers, production teams, and customers.

Education

Associate’s Degree in Industrial Manufacturing

August 2019

Skills

- Precision Machine Operation

- CNC Machining

- Flange Production

- Blueprint Reading

- Quality Control

- Machine Maintenance

Work Experience

Flange Machine Operator

- Fabricated and welded flanges to meet customer specifications and industry codes, ensuring structural integrity.

- Coordinated with design engineers to optimize flange designs and ensure proper functionality.

- Collaborated with other machine operators to ensure smooth production and timely delivery of flanges.

- Assisted in the setup and maintenance of flange machines to maximize productivity and minimize downtime.

Flange Machine Operator

- Fabricated and assembled flanges according to engineering specifications, using a variety of materials including steel, stainless steel, and aluminum.

- Operated CNC flange machines to produce precise and accurate flanges, ensuring adherence to dimensional requirements.

- Programmed and operated machines to cut, drill, and shape flanges to specific dimensions, using CAD/CAM software.

- Inspected and tested flanges to ensure adherence to quality standards, utilizing nondestructive testing (NDT) techniques.

Accomplishments

- Successfully implemented a new flange machining process that resulted in a 15% increase in productivity.

- Identified and resolved a technical issue with the flange machine, preventing downtime and ensuring seamless production.

- Trained and mentored new flange machine operators, ensuring they meet performance standards and contribute effectively to the team.

- Developed and implemented a quality control system that reduced defect rates by 25%.

- Utilized Six Sigma principles to improve machine stability and reduce vibration, leading to improved flange quality.

Awards

- Recognized for outstanding performance in meeting production targets and maintaining highquality standards.

- Received Safety Excellence Award for consistently adhering to safety protocols and maintaining a safe work environment.

- Awarded Employee of the Month for exceptional contributions to the teams success and efficiency.

Certificates

- Certified Flange Machinist

- CNC Machining Certification

- OSHA Safety Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flange Machine Operator

- Highlight your skills and experience in operating CNC flange machines, ensuring accuracy and precision in flange production.

- Quantify your accomplishments whenever possible, providing specific examples of how you contributed to the company’s success.

- Emphasize your understanding of flange designs, welding techniques, and industry codes, demonstrating your technical expertise.

- Showcase your ability to work independently and as part of a team, highlighting your communication and collaboration skills.

Essential Experience Highlights for a Strong Flange Machine Operator Resume

- Fabricated and assembled flanges according to engineering specifications, using a variety of materials including steel, stainless steel, and aluminum.

- Programmed and operated CNC flange machines to produce precise and accurate flanges, ensuring adherence to dimensional requirements.

- Inspected and tested flanges to ensure adherence to quality standards, utilizing nondestructive testing (NDT) techniques.

- Coordinated with design engineers to optimize flange designs and ensure proper functionality.

- Collaborated with other machine operators to ensure smooth production and timely delivery of flanges.

- Assisted in the setup and maintenance of flange machines to maximize productivity and minimize downtime.

Frequently Asked Questions (FAQ’s) For Flange Machine Operator

What are the primary responsibilities of a Flange Machine Operator?

The primary responsibilities of a Flange Machine Operator include fabricating and assembling flanges according to engineering specifications, programming and operating CNC flange machines, inspecting and testing flanges to ensure quality, collaborating with design engineers, and maintaining flange machines.

What skills are required to be a successful Flange Machine Operator?

Successful Flange Machine Operators typically possess skills in precision machine operation, CNC machining, flange production, blueprint reading, quality control, and machine maintenance.

What is the average salary for a Flange Machine Operator?

The average salary for a Flange Machine Operator in the United States is around $50,000 per year.

What are the growth prospects for a Flange Machine Operator?

The job outlook for Flange Machine Operators is expected to grow in the coming years due to increased demand for flanges in various industries.

What is the work environment like for a Flange Machine Operator?

Flange Machine Operators typically work in manufacturing facilities, operating CNC machines and performing inspections in a workshop setting.

What are the educational requirements for becoming a Flange Machine Operator?

While formal education requirements may vary, many Flange Machine Operators hold an associate’s degree in industrial manufacturing or a related field.

Are there any certifications available for Flange Machine Operators?

Yes, there are several certifications available for Flange Machine Operators, such as the Certified Flange Machine Operator (CFMO) certification offered by the American Welding Society (AWS).