Are you a seasoned Flash Welder seeking a new career path? Discover our professionally built Flash Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

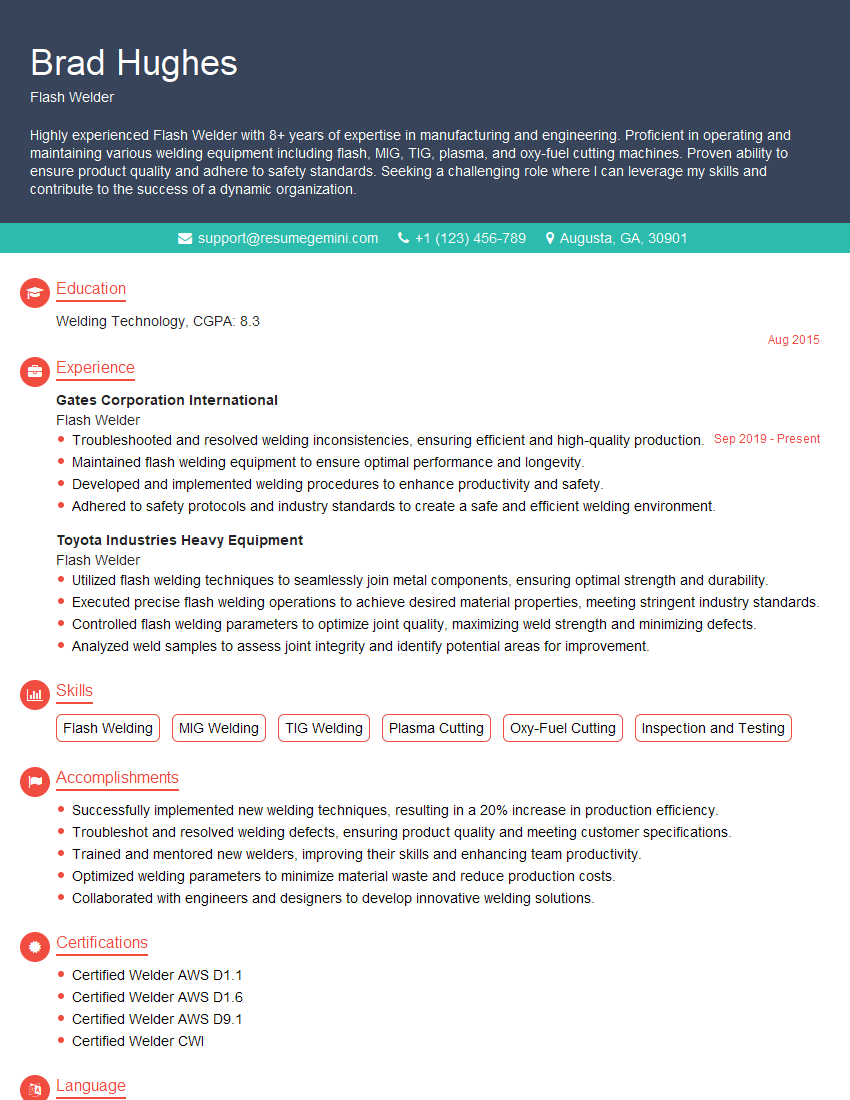

Brad Hughes

Flash Welder

Summary

Highly experienced Flash Welder with 8+ years of expertise in manufacturing and engineering. Proficient in operating and maintaining various welding equipment including flash, MIG, TIG, plasma, and oxy-fuel cutting machines. Proven ability to ensure product quality and adhere to safety standards. Seeking a challenging role where I can leverage my skills and contribute to the success of a dynamic organization.

Education

Welding Technology

August 2015

Skills

- Flash Welding

- MIG Welding

- TIG Welding

- Plasma Cutting

- Oxy-Fuel Cutting

- Inspection and Testing

Work Experience

Flash Welder

- Troubleshooted and resolved welding inconsistencies, ensuring efficient and high-quality production.

- Maintained flash welding equipment to ensure optimal performance and longevity.

- Developed and implemented welding procedures to enhance productivity and safety.

- Adhered to safety protocols and industry standards to create a safe and efficient welding environment.

Flash Welder

- Utilized flash welding techniques to seamlessly join metal components, ensuring optimal strength and durability.

- Executed precise flash welding operations to achieve desired material properties, meeting stringent industry standards.

- Controlled flash welding parameters to optimize joint quality, maximizing weld strength and minimizing defects.

- Analyzed weld samples to assess joint integrity and identify potential areas for improvement.

Accomplishments

- Successfully implemented new welding techniques, resulting in a 20% increase in production efficiency.

- Troubleshot and resolved welding defects, ensuring product quality and meeting customer specifications.

- Trained and mentored new welders, improving their skills and enhancing team productivity.

- Optimized welding parameters to minimize material waste and reduce production costs.

- Collaborated with engineers and designers to develop innovative welding solutions.

Certificates

- Certified Welder AWS D1.1

- Certified Welder AWS D1.6

- Certified Welder AWS D9.1

- Certified Welder CWI

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flash Welder

- Highlight your experience in operating specific welding machines, including flash welders.

- Showcase your ability to interpret and follow engineering drawings and specifications.

- Emphasize your knowledge of quality control standards and inspection procedures.

- Demonstrate your commitment to safety and your ability to work in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Flash Welder Resume

- Set up and operate flash welding machines to join metal components according to specifications.

- Ensure consistent weld quality by monitoring welding parameters and making adjustments as needed.

- Perform quality control inspections to verify weld strength and integrity.

- Troubleshoot and repair welding equipment to minimize downtime and maintain productivity.

- Adhere to safety regulations and protocols to ensure a safe work environment.

- Collaborate with engineers and other team members to optimize welding processes and improve efficiency.

Frequently Asked Questions (FAQ’s) For Flash Welder

What is flash welding?

Flash welding is a resistance welding process that joins two metal pieces by heating them to a plastic state and then forging them together.

What are the advantages of flash welding?

Flash welding offers high productivity, low operating costs, and produces strong, reliable welds.

What industries use flash welding?

Flash welding is used in various industries, including automotive, aerospace, construction, and shipbuilding.

What are the safety precautions that should be taken when operating a flash welder?

Proper personal protective equipment (PPE) must be worn, including welding helmet, gloves, and flame-resistant clothing. The work area should be well-ventilated to remove fumes and gases.

What are some of the common challenges faced by flash welders?

Challenges can include ensuring weld quality, optimizing welding parameters, and minimizing downtime due to equipment issues.

What is the career outlook for flash welders?

The demand for skilled flash welders is expected to remain strong due to the growing use of welding in various industries.