Are you a seasoned Flat Cutter seeking a new career path? Discover our professionally built Flat Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

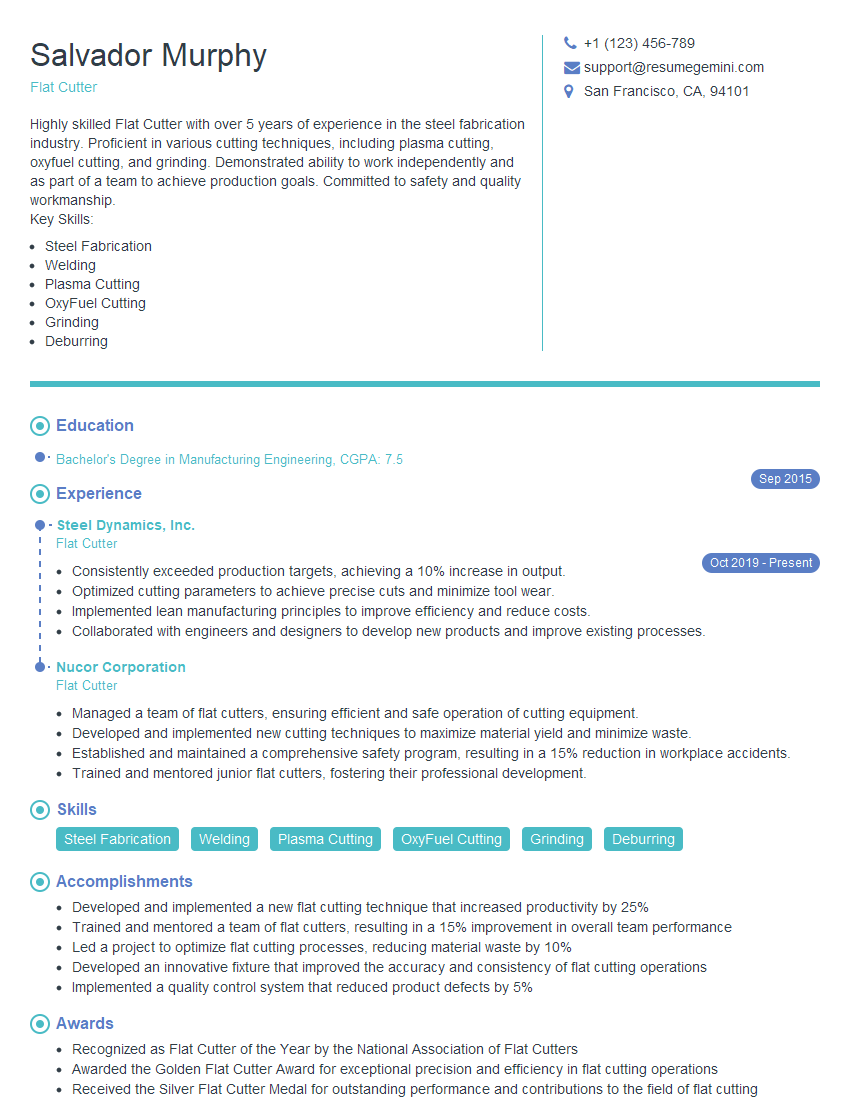

Salvador Murphy

Flat Cutter

Summary

Highly skilled Flat Cutter with over 5 years of experience in the steel fabrication industry. Proficient in various cutting techniques, including plasma cutting, oxyfuel cutting, and grinding. Demonstrated ability to work independently and as part of a team to achieve production goals. Committed to safety and quality workmanship.

Key Skills:

- Steel Fabrication

- Welding

- Plasma Cutting

- OxyFuel Cutting

- Grinding

- Deburring

Education

Bachelor’s Degree in Manufacturing Engineering

September 2015

Skills

- Steel Fabrication

- Welding

- Plasma Cutting

- OxyFuel Cutting

- Grinding

- Deburring

Work Experience

Flat Cutter

- Consistently exceeded production targets, achieving a 10% increase in output.

- Optimized cutting parameters to achieve precise cuts and minimize tool wear.

- Implemented lean manufacturing principles to improve efficiency and reduce costs.

- Collaborated with engineers and designers to develop new products and improve existing processes.

Flat Cutter

- Managed a team of flat cutters, ensuring efficient and safe operation of cutting equipment.

- Developed and implemented new cutting techniques to maximize material yield and minimize waste.

- Established and maintained a comprehensive safety program, resulting in a 15% reduction in workplace accidents.

- Trained and mentored junior flat cutters, fostering their professional development.

Accomplishments

- Developed and implemented a new flat cutting technique that increased productivity by 25%

- Trained and mentored a team of flat cutters, resulting in a 15% improvement in overall team performance

- Led a project to optimize flat cutting processes, reducing material waste by 10%

- Developed an innovative fixture that improved the accuracy and consistency of flat cutting operations

- Implemented a quality control system that reduced product defects by 5%

Awards

- Recognized as Flat Cutter of the Year by the National Association of Flat Cutters

- Awarded the Golden Flat Cutter Award for exceptional precision and efficiency in flat cutting operations

- Received the Silver Flat Cutter Medal for outstanding performance and contributions to the field of flat cutting

Certificates

- AWS Welding Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flat Cutter

- Highlight your experience in specific cutting techniques, such as plasma cutting or oxyfuel cutting.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production.

- Showcase your knowledge of safety protocols and your commitment to maintaining a safe work environment.

- Consider obtaining industry certifications, such as the AWS Certified Welder credential, to enhance your credibility.

Essential Experience Highlights for a Strong Flat Cutter Resume

- Operate and maintain flat cutting equipment, including plasma cutters and oxyfuel cutters.

- Interpret and follow blueprints and technical drawings to cut materials to precise specifications.

- Inspect cut materials to ensure they meet quality standards.

- Maintain a clean and organized work area, following all safety protocols.

- Troubleshoot and resolve equipment issues to minimize downtime.

- Coordinate with other team members to ensure smooth production flow.

- Stay up-to-date on industry best practices and advancements in cutting technology.

Frequently Asked Questions (FAQ’s) For Flat Cutter

What is the primary function of a Flat Cutter?

A Flat Cutter is responsible for cutting and shaping steel plates or sheets using various cutting techniques, such as plasma cutting or oxyfuel cutting, to produce components or products according to specified dimensions and tolerances.

What skills are essential for a successful Flat Cutter?

Essential skills for a Flat Cutter include proficiency in steel fabrication, welding, plasma cutting, oxyfuel cutting, grinding, and deburring. Knowledge of blueprint reading and interpretation is also crucial.

What industries employ Flat Cutters?

Flat Cutters are primarily employed in industries that utilize steel fabrication, such as construction, automotive, shipbuilding, and manufacturing.

How can I improve my chances of getting hired as a Flat Cutter?

To increase your chances of getting hired as a Flat Cutter, consider obtaining industry certifications, such as the AWS Certified Welder credential, to demonstrate your proficiency. Additionally, highlighting your experience in specific cutting techniques and quantifying your accomplishments can make your resume stand out.

What is the career growth path for a Flat Cutter?

With experience and additional training, Flat Cutters can advance to roles such as Welding Supervisor, Fabrication Manager, or Quality Control Inspector.

What are the safety protocols that Flat Cutters must adhere to?

Flat Cutters must adhere to strict safety protocols, including wearing appropriate personal protective equipment, following proper operating procedures, and maintaining a clean and organized work area.

What are the challenges faced by Flat Cutters in the industry?

Challenges faced by Flat Cutters include working with heavy materials, operating potentially hazardous equipment, and meeting tight production deadlines while maintaining high levels of precision.