Are you a seasoned Flatlock Sewing Machine Operator seeking a new career path? Discover our professionally built Flatlock Sewing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

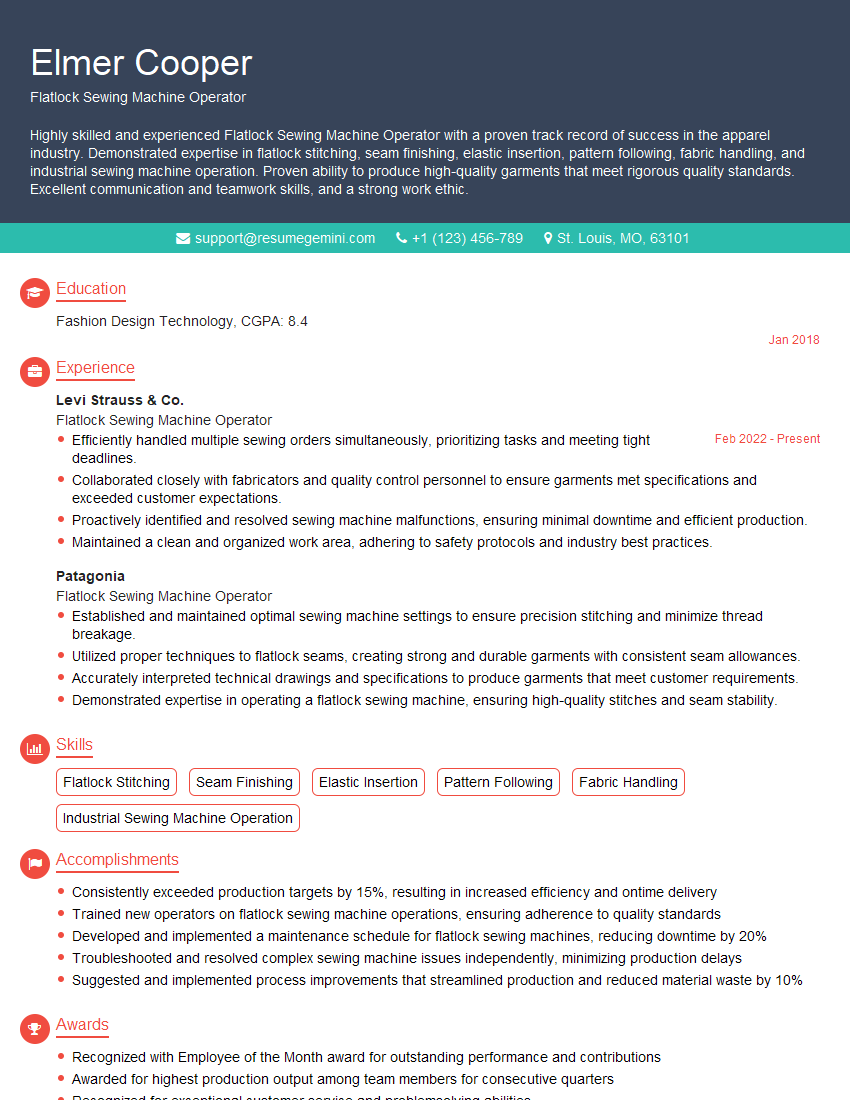

Elmer Cooper

Flatlock Sewing Machine Operator

Summary

Highly skilled and experienced Flatlock Sewing Machine Operator with a proven track record of success in the apparel industry. Demonstrated expertise in flatlock stitching, seam finishing, elastic insertion, pattern following, fabric handling, and industrial sewing machine operation. Proven ability to produce high-quality garments that meet rigorous quality standards. Excellent communication and teamwork skills, and a strong work ethic.

Education

Fashion Design Technology

January 2018

Skills

- Flatlock Stitching

- Seam Finishing

- Elastic Insertion

- Pattern Following

- Fabric Handling

- Industrial Sewing Machine Operation

Work Experience

Flatlock Sewing Machine Operator

- Efficiently handled multiple sewing orders simultaneously, prioritizing tasks and meeting tight deadlines.

- Collaborated closely with fabricators and quality control personnel to ensure garments met specifications and exceeded customer expectations.

- Proactively identified and resolved sewing machine malfunctions, ensuring minimal downtime and efficient production.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

Flatlock Sewing Machine Operator

- Established and maintained optimal sewing machine settings to ensure precision stitching and minimize thread breakage.

- Utilized proper techniques to flatlock seams, creating strong and durable garments with consistent seam allowances.

- Accurately interpreted technical drawings and specifications to produce garments that meet customer requirements.

- Demonstrated expertise in operating a flatlock sewing machine, ensuring high-quality stitches and seam stability.

Accomplishments

- Consistently exceeded production targets by 15%, resulting in increased efficiency and ontime delivery

- Trained new operators on flatlock sewing machine operations, ensuring adherence to quality standards

- Developed and implemented a maintenance schedule for flatlock sewing machines, reducing downtime by 20%

- Troubleshooted and resolved complex sewing machine issues independently, minimizing production delays

- Suggested and implemented process improvements that streamlined production and reduced material waste by 10%

Awards

- Recognized with Employee of the Month award for outstanding performance and contributions

- Awarded for highest production output among team members for consecutive quarters

- Recognized for exceptional customer service and problemsolving abilities

- Awarded for innovation and creativity in developing new production techniques

Certificates

- Certified Flatlock Sewing Machine Operator

- OSHA Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flatlock Sewing Machine Operator

- Highlight your experience and skills in flatlock stitching, seam finishing, and elastic insertion.

- Quantify your accomplishments whenever possible to demonstrate your impact on the business.

- Emphasize your attention to detail and commitment to producing high-quality garments.

- Showcase your teamwork skills and ability to work in a fast-paced environment.

Essential Experience Highlights for a Strong Flatlock Sewing Machine Operator Resume

- Operate flatlock sewing machines to stitch garments and other fabric items

- Finish seams using various techniques, including overlock stitching, serging, and binding

- Insert elastic into garments to provide a snug fit and comfort

- Follow patterns and instructions to ensure accurate stitching and garment construction

- Handle and inspect fabrics to ensure they are free of defects and meet quality standards

- Maintain and clean sewing machines and other equipment to ensure optimal performance

- Collaborate with other team members to ensure efficient and productive workflow

Frequently Asked Questions (FAQ’s) For Flatlock Sewing Machine Operator

What is flatlock stitching?

Flatlock stitching is a type of sewing technique that creates a flat and durable seam with a chain-stitch appearance.

What are the different types of flatlock sewing machines?

There are two main types of flatlock sewing machines: two-needle and three-needle machines. Two-needle machines create a two-thread stitch, while three-needle machines create a three-thread stitch.

What materials can be sewn with a flatlock sewing machine?

Flatlock sewing machines can be used to sew a variety of materials, including cotton, polyester, nylon, and spandex.

What are the applications of flatlock stitching?

Flatlock stitching is commonly used in the construction of garments, such as t-shirts, sweatshirts, and sportswear. It is also used in the production of home textiles, such as blankets and curtains.

What are the benefits of using a flatlock sewing machine?

Flatlock sewing machines offer a number of benefits, including increased durability, improved seam appearance, and reduced production time.

What are the challenges of using a flatlock sewing machine?

Flatlock sewing machines can be challenging to operate, and require a high level of skill and experience to produce high-quality results.