Are you a seasoned Flexographic Press Set-Up Operator seeking a new career path? Discover our professionally built Flexographic Press Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

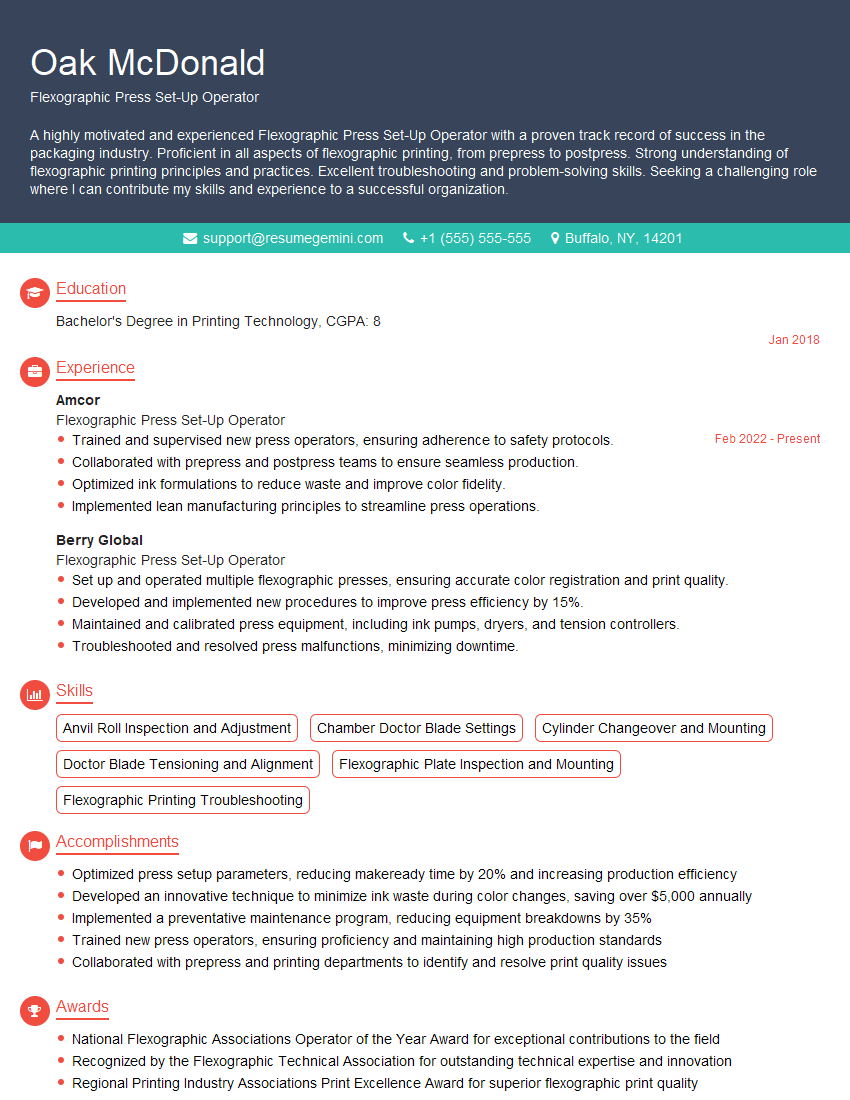

Oak McDonald

Flexographic Press Set-Up Operator

Summary

A highly motivated and experienced Flexographic Press Set-Up Operator with a proven track record of success in the packaging industry. Proficient in all aspects of flexographic printing, from prepress to postpress. Strong understanding of flexographic printing principles and practices. Excellent troubleshooting and problem-solving skills. Seeking a challenging role where I can contribute my skills and experience to a successful organization.

Education

Bachelor’s Degree in Printing Technology

January 2018

Skills

- Anvil Roll Inspection and Adjustment

- Chamber Doctor Blade Settings

- Cylinder Changeover and Mounting

- Doctor Blade Tensioning and Alignment

- Flexographic Plate Inspection and Mounting

- Flexographic Printing Troubleshooting

Work Experience

Flexographic Press Set-Up Operator

- Trained and supervised new press operators, ensuring adherence to safety protocols.

- Collaborated with prepress and postpress teams to ensure seamless production.

- Optimized ink formulations to reduce waste and improve color fidelity.

- Implemented lean manufacturing principles to streamline press operations.

Flexographic Press Set-Up Operator

- Set up and operated multiple flexographic presses, ensuring accurate color registration and print quality.

- Developed and implemented new procedures to improve press efficiency by 15%.

- Maintained and calibrated press equipment, including ink pumps, dryers, and tension controllers.

- Troubleshooted and resolved press malfunctions, minimizing downtime.

Accomplishments

- Optimized press setup parameters, reducing makeready time by 20% and increasing production efficiency

- Developed an innovative technique to minimize ink waste during color changes, saving over $5,000 annually

- Implemented a preventative maintenance program, reducing equipment breakdowns by 35%

- Trained new press operators, ensuring proficiency and maintaining high production standards

- Collaborated with prepress and printing departments to identify and resolve print quality issues

Awards

- National Flexographic Associations Operator of the Year Award for exceptional contributions to the field

- Recognized by the Flexographic Technical Association for outstanding technical expertise and innovation

- Regional Printing Industry Associations Print Excellence Award for superior flexographic print quality

Certificates

- Flexographic Press Operators Certification Program

- FTA Flexographic Quality Control Technician

- FTA Master Flexographer

- Print Quality Control Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flexographic Press Set-Up Operator

- Highlight your experience and skills in flexographic printing, especially in set-up and operation.

- Showcase your knowledge of flexographic printing principles and practices.

- Emphasize your troubleshooting and problem-solving abilities.

- Quantify your accomplishments and results whenever possible.

Essential Experience Highlights for a Strong Flexographic Press Set-Up Operator Resume

- Inspected and adjusted anvil rolls to ensure proper contact with the printing plate

- Set chamber doctor blade settings to optimize ink flow and prevent flooding

- Changed and mounted printing cylinders, ensuring proper alignment and tension

- Tensioned and aligned doctor blades to achieve optimal ink transfer

- Inspected and mounted flexographic printing plates, ensuring proper registration and dot gain

- Troubleshooted and resolved flexographic printing problems, such as registration errors, ink mottle, and scumming

Frequently Asked Questions (FAQ’s) For Flexographic Press Set-Up Operator

What are the key skills required for a Flexographic Press Set-Up Operator?

The key skills required for a Flexographic Press Set-Up Operator include: anvil roll inspection and adjustment, chamber doctor blade settings, cylinder changeover and mounting, doctor blade tensioning and alignment, flexographic plate inspection and mounting, and flexographic printing troubleshooting.

What is the role of a Flexographic Press Set-Up Operator?

The role of a Flexographic Press Set-Up Operator is to ensure that the flexographic printing press is properly set up and calibrated for optimal printing performance. This includes inspecting and adjusting anvil rolls, setting chamber doctor blade settings, changing and mounting printing cylinders, tensioning and aligning doctor blades, inspecting and mounting flexographic printing plates, and troubleshooting flexographic printing problems.

What are the career prospects for a Flexographic Press Set-Up Operator?

The career prospects for a Flexographic Press Set-Up Operator are good, as there is a growing demand for skilled flexographic printing professionals. With experience and training, Flexographic Press Set-Up Operators can advance to supervisory or management positions.

What is the average salary for a Flexographic Press Set-Up Operator?

The average salary for a Flexographic Press Set-Up Operator in the United States is around $50,000 per year.

What are the working conditions for a Flexographic Press Set-Up Operator?

Flexographic Press Set-Up Operators typically work in a manufacturing environment, and may be exposed to noise, dust, and chemicals. They may also need to work overtime or on weekends to meet production deadlines.

What are the educational requirements for a Flexographic Press Set-Up Operator?

Flexographic Press Set-Up Operators typically have a high school diploma or equivalent, and may have some college coursework in printing technology or a related field.