Are you a seasoned Flexographic Printing Press Operator seeking a new career path? Discover our professionally built Flexographic Printing Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

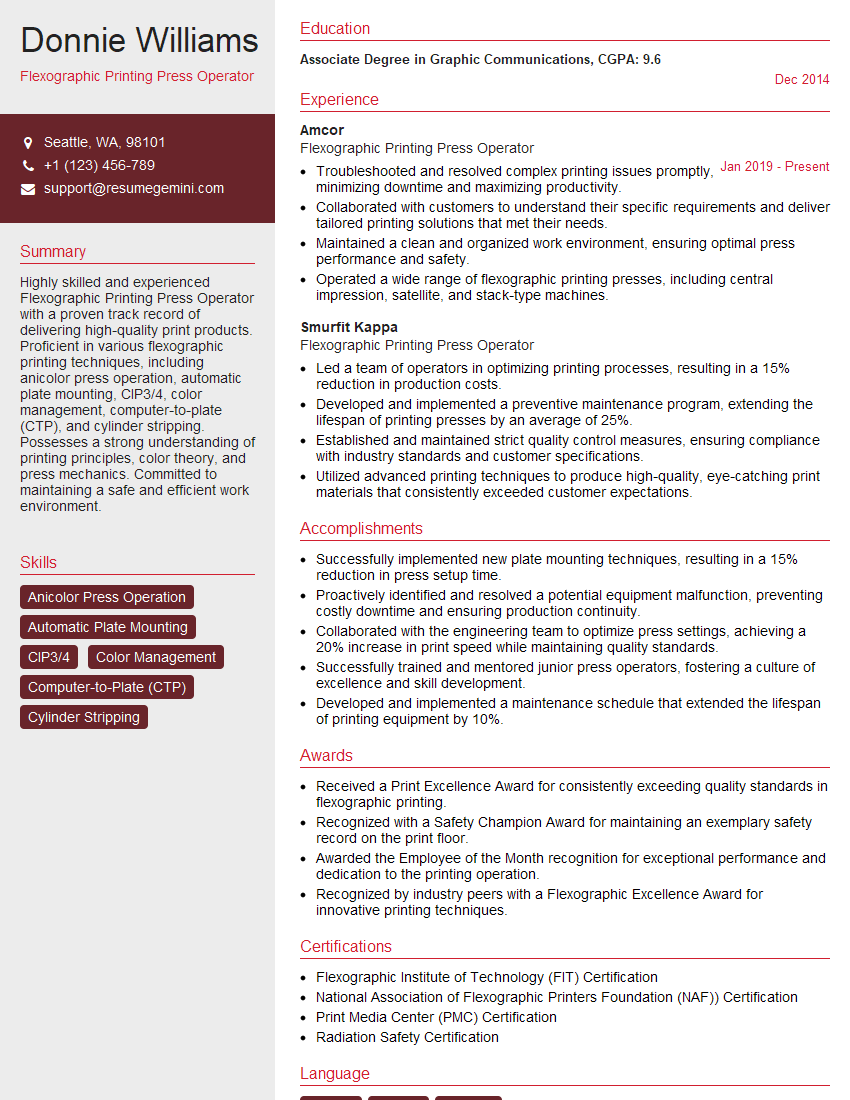

Donnie Williams

Flexographic Printing Press Operator

Summary

Highly skilled and experienced Flexographic Printing Press Operator with a proven track record of delivering high-quality print products. Proficient in various flexographic printing techniques, including anicolor press operation, automatic plate mounting, CIP3/4, color management, computer-to-plate (CTP), and cylinder stripping. Possesses a strong understanding of printing principles, color theory, and press mechanics. Committed to maintaining a safe and efficient work environment.

Education

Associate Degree in Graphic Communications

December 2014

Skills

- Anicolor Press Operation

- Automatic Plate Mounting

- CIP3/4

- Color Management

- Computer-to-Plate (CTP)

- Cylinder Stripping

Work Experience

Flexographic Printing Press Operator

- Troubleshooted and resolved complex printing issues promptly, minimizing downtime and maximizing productivity.

- Collaborated with customers to understand their specific requirements and deliver tailored printing solutions that met their needs.

- Maintained a clean and organized work environment, ensuring optimal press performance and safety.

- Operated a wide range of flexographic printing presses, including central impression, satellite, and stack-type machines.

Flexographic Printing Press Operator

- Led a team of operators in optimizing printing processes, resulting in a 15% reduction in production costs.

- Developed and implemented a preventive maintenance program, extending the lifespan of printing presses by an average of 25%.

- Established and maintained strict quality control measures, ensuring compliance with industry standards and customer specifications.

- Utilized advanced printing techniques to produce high-quality, eye-catching print materials that consistently exceeded customer expectations.

Accomplishments

- Successfully implemented new plate mounting techniques, resulting in a 15% reduction in press setup time.

- Proactively identified and resolved a potential equipment malfunction, preventing costly downtime and ensuring production continuity.

- Collaborated with the engineering team to optimize press settings, achieving a 20% increase in print speed while maintaining quality standards.

- Successfully trained and mentored junior press operators, fostering a culture of excellence and skill development.

- Developed and implemented a maintenance schedule that extended the lifespan of printing equipment by 10%.

Awards

- Received a Print Excellence Award for consistently exceeding quality standards in flexographic printing.

- Recognized with a Safety Champion Award for maintaining an exemplary safety record on the print floor.

- Awarded the Employee of the Month recognition for exceptional performance and dedication to the printing operation.

- Recognized by industry peers with a Flexographic Excellence Award for innovative printing techniques.

Certificates

- Flexographic Institute of Technology (FIT) Certification

- National Association of Flexographic Printers Foundation (NAF)) Certification

- Print Media Center (PMC) Certification

- Radiation Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flexographic Printing Press Operator

- Highlight your skills and experience in flexographic printing, including specific techniques and technologies.

- Showcase your knowledge of printing principles, color theory, and press mechanics.

- Emphasize your commitment to quality and safety.

- Include examples of your work and quantify your accomplishments whenever possible.

Essential Experience Highlights for a Strong Flexographic Printing Press Operator Resume

- Operate and maintain flexographic printing presses to produce high-quality printed materials.

- Set up and calibrate printing presses according to job specifications.

- Monitor printing presses during operation and make adjustments as needed to ensure optimal print quality.

- Troubleshoot and resolve printing problems to minimize downtime.

- Maintain a clean and organized work area.

- Follow established safety procedures and wear appropriate personal protective equipment.

- Work effectively as part of a team to meet production goals.

Frequently Asked Questions (FAQ’s) For Flexographic Printing Press Operator

What is flexographic printing?

Flexographic printing is a printing process that uses flexible relief plates to transfer ink to a substrate. It is commonly used for printing packaging materials, labels, and other flexible substrates.

What are the benefits of flexographic printing?

Flexographic printing offers several benefits, including high print quality, versatility, and cost-effectiveness. It is also a sustainable printing process that produces minimal waste.

What are the different types of flexographic printing presses?

There are several types of flexographic printing presses, including central impression, stack type, and CI flexo presses. Each type of press has its own advantages and disadvantages depending on the specific printing application.

What are the key skills required for a Flexographic Printing Press Operator?

Key skills for a Flexographic Printing Press Operator include knowledge of flexographic printing principles, experience in operating flexographic printing presses, ability to troubleshoot and resolve printing problems, and commitment to safety.

What are the career prospects for a Flexographic Printing Press Operator?

Flexographic Printing Press Operators are in high demand in the printing industry. They can find employment in various industries, including packaging, labels, and other flexible printing applications.

How can I become a Flexographic Printing Press Operator?

To become a Flexographic Printing Press Operator, you can obtain an associate degree in graphic communications or a related field and gain experience in flexographic printing through internships or entry-level positions.