Are you a seasoned Flotation Operator seeking a new career path? Discover our professionally built Flotation Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

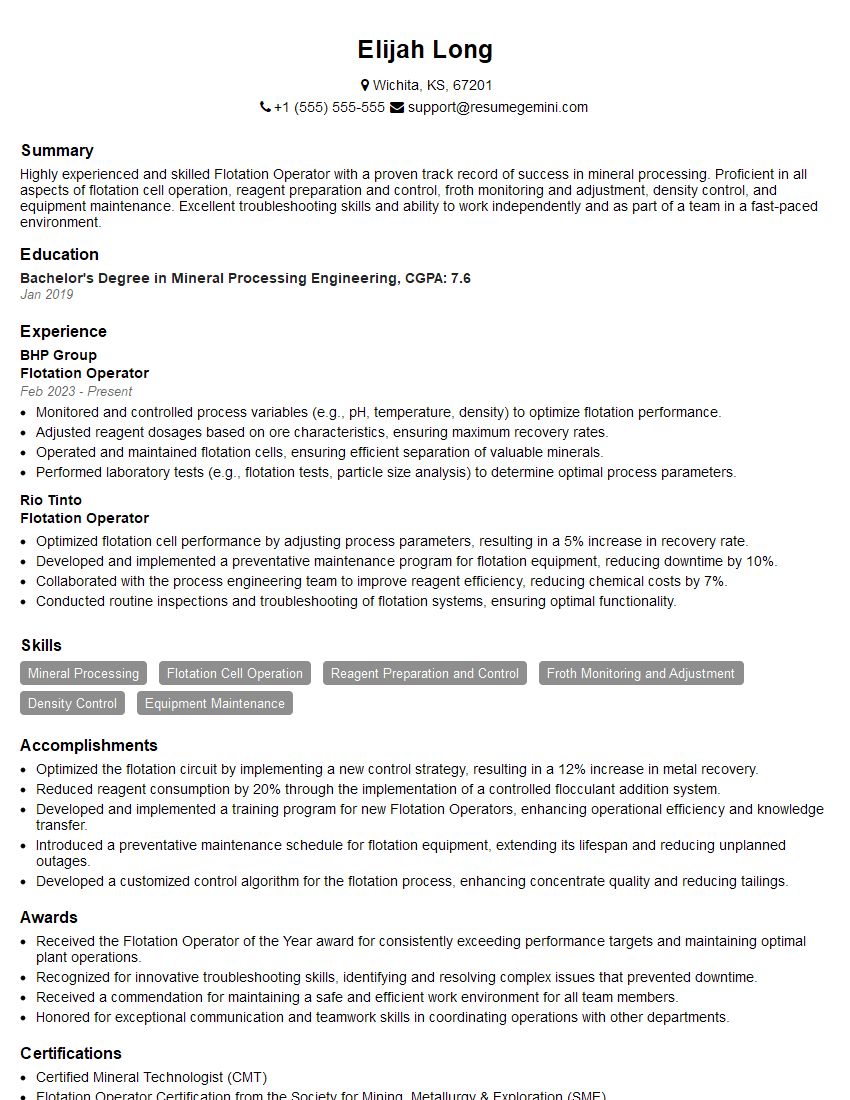

Elijah Long

Flotation Operator

Summary

Highly experienced and skilled Flotation Operator with a proven track record of success in mineral processing. Proficient in all aspects of flotation cell operation, reagent preparation and control, froth monitoring and adjustment, density control, and equipment maintenance. Excellent troubleshooting skills and ability to work independently and as part of a team in a fast-paced environment.

Education

Bachelor’s Degree in Mineral Processing Engineering

January 2019

Skills

- Mineral Processing

- Flotation Cell Operation

- Reagent Preparation and Control

- Froth Monitoring and Adjustment

- Density Control

- Equipment Maintenance

Work Experience

Flotation Operator

- Monitored and controlled process variables (e.g., pH, temperature, density) to optimize flotation performance.

- Adjusted reagent dosages based on ore characteristics, ensuring maximum recovery rates.

- Operated and maintained flotation cells, ensuring efficient separation of valuable minerals.

- Performed laboratory tests (e.g., flotation tests, particle size analysis) to determine optimal process parameters.

Flotation Operator

- Optimized flotation cell performance by adjusting process parameters, resulting in a 5% increase in recovery rate.

- Developed and implemented a preventative maintenance program for flotation equipment, reducing downtime by 10%.

- Collaborated with the process engineering team to improve reagent efficiency, reducing chemical costs by 7%.

- Conducted routine inspections and troubleshooting of flotation systems, ensuring optimal functionality.

Accomplishments

- Optimized the flotation circuit by implementing a new control strategy, resulting in a 12% increase in metal recovery.

- Reduced reagent consumption by 20% through the implementation of a controlled flocculant addition system.

- Developed and implemented a training program for new Flotation Operators, enhancing operational efficiency and knowledge transfer.

- Introduced a preventative maintenance schedule for flotation equipment, extending its lifespan and reducing unplanned outages.

- Developed a customized control algorithm for the flotation process, enhancing concentrate quality and reducing tailings.

Awards

- Received the Flotation Operator of the Year award for consistently exceeding performance targets and maintaining optimal plant operations.

- Recognized for innovative troubleshooting skills, identifying and resolving complex issues that prevented downtime.

- Received a commendation for maintaining a safe and efficient work environment for all team members.

- Honored for exceptional communication and teamwork skills in coordinating operations with other departments.

Certificates

- Certified Mineral Technologist (CMT)

- Flotation Operator Certification from the Society for Mining, Metallurgy & Exploration (SME)

- OSHA Safety Training Certification

- Hazmat Handling Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flotation Operator

- Highlight your experience and skills in flotation cell operation and mineral processing.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Demonstrate your knowledge of flotation theory and best practices.

- Showcase your ability to work independently and as part of a team in a fast-paced environment.

Essential Experience Highlights for a Strong Flotation Operator Resume

- Operate flotation cells to separate minerals from gangue materials

- Prepare and control reagents to optimize flotation efficiency

- Monitor and adjust froth levels to ensure optimal mineral recovery

- Control density of flotation pulp to maintain desired separation

- Perform equipment maintenance and repairs to ensure smooth operation

- Troubleshoot and resolve operational issues to minimize downtime

- Maintain accurate records and provide performance reports

Frequently Asked Questions (FAQ’s) For Flotation Operator

What is the role of a Flotation Operator?

A Flotation Operator is responsible for operating flotation cells to separate minerals from gangue materials, preparing and controlling reagents, monitoring and adjusting froth levels, controlling density of flotation pulp, performing equipment maintenance and repairs, and troubleshooting and resolving operational issues.

What are the key skills required to be a successful Flotation Operator?

Key skills for a Flotation Operator include experience in flotation cell operation, mineral processing, reagent preparation and control, froth monitoring and adjustment, density control, and equipment maintenance.

What is the educational background required to become a Flotation Operator?

A Bachelor’s Degree in Mineral Processing Engineering or a related field is typically required to become a Flotation Operator.

What are the career prospects for Flotation Operators?

Flotation Operators can advance to supervisory roles such as Flotation Supervisor or Mineral Processing Superintendent.

What is the salary range for Flotation Operators?

The salary range for Flotation Operators varies depending on experience, location, and company. According to Indeed, the average salary for a Flotation Operator in the United States is around $60,000 per year.

What are the working conditions like for Flotation Operators?

Flotation Operators typically work in mineral processing plants, which can be noisy and dusty. They may also work in outdoor conditions, which can be hazardous.