Are you a seasoned Fluid Power Mechanic seeking a new career path? Discover our professionally built Fluid Power Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

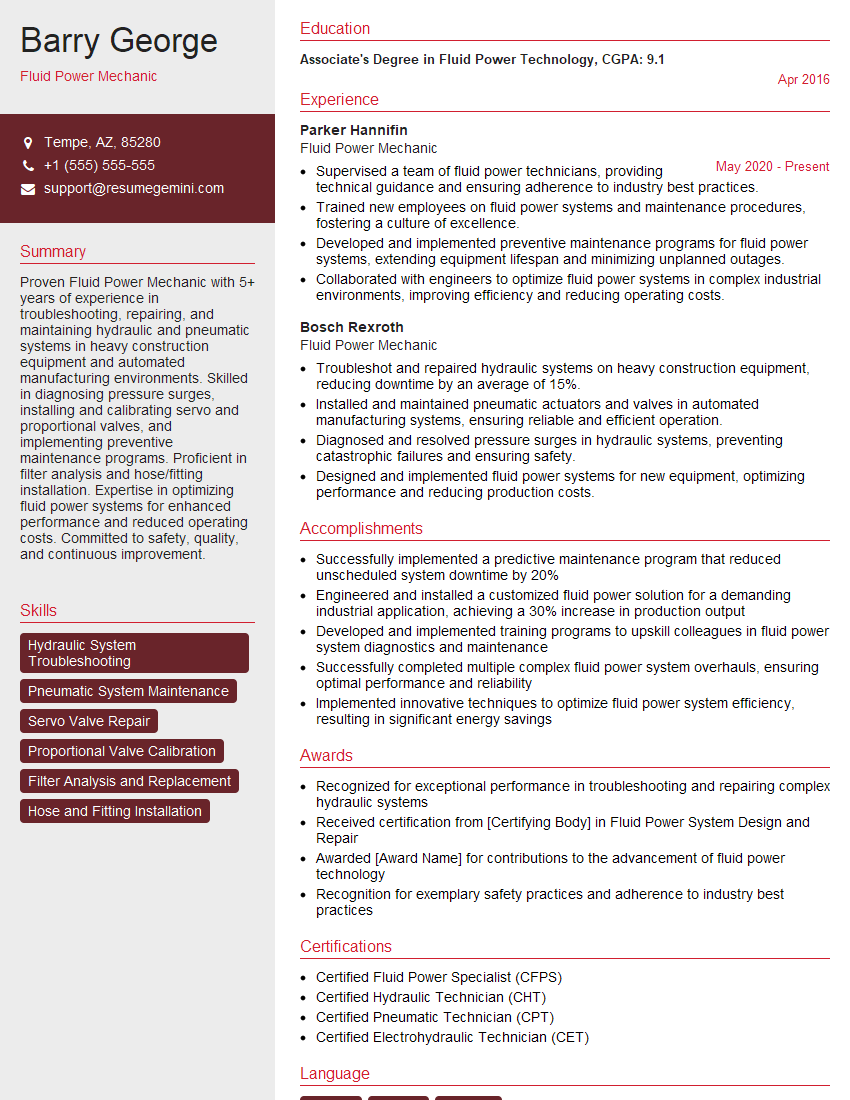

Barry George

Fluid Power Mechanic

Summary

Proven Fluid Power Mechanic with 5+ years of experience in troubleshooting, repairing, and maintaining hydraulic and pneumatic systems in heavy construction equipment and automated manufacturing environments. Skilled in diagnosing pressure surges, installing and calibrating servo and proportional valves, and implementing preventive maintenance programs. Proficient in filter analysis and hose/fitting installation. Expertise in optimizing fluid power systems for enhanced performance and reduced operating costs. Committed to safety, quality, and continuous improvement.

Education

Associate’s Degree in Fluid Power Technology

April 2016

Skills

- Hydraulic System Troubleshooting

- Pneumatic System Maintenance

- Servo Valve Repair

- Proportional Valve Calibration

- Filter Analysis and Replacement

- Hose and Fitting Installation

Work Experience

Fluid Power Mechanic

- Supervised a team of fluid power technicians, providing technical guidance and ensuring adherence to industry best practices.

- Trained new employees on fluid power systems and maintenance procedures, fostering a culture of excellence.

- Developed and implemented preventive maintenance programs for fluid power systems, extending equipment lifespan and minimizing unplanned outages.

- Collaborated with engineers to optimize fluid power systems in complex industrial environments, improving efficiency and reducing operating costs.

Fluid Power Mechanic

- Troubleshot and repaired hydraulic systems on heavy construction equipment, reducing downtime by an average of 15%.

- Installed and maintained pneumatic actuators and valves in automated manufacturing systems, ensuring reliable and efficient operation.

- Diagnosed and resolved pressure surges in hydraulic systems, preventing catastrophic failures and ensuring safety.

- Designed and implemented fluid power systems for new equipment, optimizing performance and reducing production costs.

Accomplishments

- Successfully implemented a predictive maintenance program that reduced unscheduled system downtime by 20%

- Engineered and installed a customized fluid power solution for a demanding industrial application, achieving a 30% increase in production output

- Developed and implemented training programs to upskill colleagues in fluid power system diagnostics and maintenance

- Successfully completed multiple complex fluid power system overhauls, ensuring optimal performance and reliability

- Implemented innovative techniques to optimize fluid power system efficiency, resulting in significant energy savings

Awards

- Recognized for exceptional performance in troubleshooting and repairing complex hydraulic systems

- Received certification from [Certifying Body] in Fluid Power System Design and Repair

- Awarded [Award Name] for contributions to the advancement of fluid power technology

- Recognition for exemplary safety practices and adherence to industry best practices

Certificates

- Certified Fluid Power Specialist (CFPS)

- Certified Hydraulic Technician (CHT)

- Certified Pneumatic Technician (CPT)

- Certified Electrohydraulic Technician (CET)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fluid Power Mechanic

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your problem-solving abilities and technical expertise.

- Emphasize your commitment to safety and quality.

- Showcase your experience in implementing preventive maintenance programs.

- Tailor your resume to each specific job application, highlighting the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Fluid Power Mechanic Resume

- Troubleshoot and repair hydraulic and pneumatic systems on heavy equipment and automated machinery.

- Install, maintain, and calibrate servo and proportional valves to ensure accurate and reliable system operation.

- Diagnose and resolve pressure surges and other system malfunctions to prevent catastrophic failures.

- Design and implement fluid power systems for new equipment, optimizing performance and efficiency.

- Supervise and train fluid power technicians, ensuring adherence to best practices and safety guidelines.

- Develop and implement preventive maintenance programs to extend equipment lifespan and minimize downtime.

- Collaborate with engineers to optimize fluid power systems in complex industrial environments.

Frequently Asked Questions (FAQ’s) For Fluid Power Mechanic

What are the primary responsibilities of a Fluid Power Mechanic?

Fluid Power Mechanics are responsible for installing, maintaining, and repairing hydraulic and pneumatic systems in a variety of industrial and commercial applications.

What are the key skills required for a Fluid Power Mechanic?

Key skills for a Fluid Power Mechanic include troubleshooting, repair, installation, maintenance, and calibration of hydraulic and pneumatic systems.

What are the career prospects for a Fluid Power Mechanic?

Fluid Power Mechanics are in high demand due to the increasing use of hydraulic and pneumatic systems in various industries. Career prospects include advancement to supervisory or management roles.

What are the educational requirements for a Fluid Power Mechanic?

While formal education is not always required, most Fluid Power Mechanics have an associate’s degree or technical diploma in fluid power technology.

What are the safety considerations for a Fluid Power Mechanic?

Fluid Power Mechanics must adhere to strict safety guidelines due to the potential hazards associated with high-pressure hydraulic and pneumatic systems.

What are the common industries that employ Fluid Power Mechanics?

Fluid Power Mechanics are employed in various industries, including manufacturing, construction, mining, and transportation.

What is the earning potential for a Fluid Power Mechanic?

The earning potential for a Fluid Power Mechanic varies depending on experience, location, and industry. However, it is generally a well-paying trade.