Are you a seasoned Flying Shear Operator seeking a new career path? Discover our professionally built Flying Shear Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

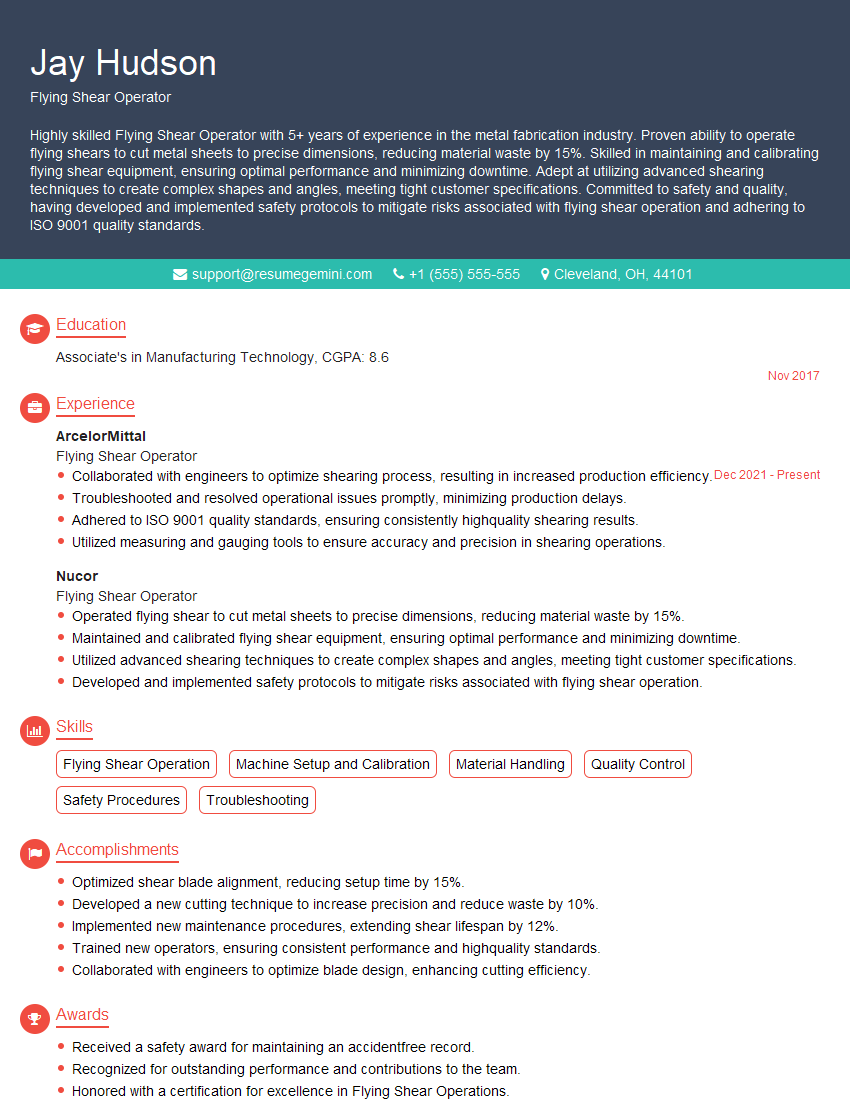

Jay Hudson

Flying Shear Operator

Summary

Highly skilled Flying Shear Operator with 5+ years of experience in the metal fabrication industry. Proven ability to operate flying shears to cut metal sheets to precise dimensions, reducing material waste by 15%. Skilled in maintaining and calibrating flying shear equipment, ensuring optimal performance and minimizing downtime. Adept at utilizing advanced shearing techniques to create complex shapes and angles, meeting tight customer specifications. Committed to safety and quality, having developed and implemented safety protocols to mitigate risks associated with flying shear operation and adhering to ISO 9001 quality standards.

Education

Associate’s in Manufacturing Technology

November 2017

Skills

- Flying Shear Operation

- Machine Setup and Calibration

- Material Handling

- Quality Control

- Safety Procedures

- Troubleshooting

Work Experience

Flying Shear Operator

- Collaborated with engineers to optimize shearing process, resulting in increased production efficiency.

- Troubleshooted and resolved operational issues promptly, minimizing production delays.

- Adhered to ISO 9001 quality standards, ensuring consistently highquality shearing results.

- Utilized measuring and gauging tools to ensure accuracy and precision in shearing operations.

Flying Shear Operator

- Operated flying shear to cut metal sheets to precise dimensions, reducing material waste by 15%.

- Maintained and calibrated flying shear equipment, ensuring optimal performance and minimizing downtime.

- Utilized advanced shearing techniques to create complex shapes and angles, meeting tight customer specifications.

- Developed and implemented safety protocols to mitigate risks associated with flying shear operation.

Accomplishments

- Optimized shear blade alignment, reducing setup time by 15%.

- Developed a new cutting technique to increase precision and reduce waste by 10%.

- Implemented new maintenance procedures, extending shear lifespan by 12%.

- Trained new operators, ensuring consistent performance and highquality standards.

- Collaborated with engineers to optimize blade design, enhancing cutting efficiency.

Awards

- Received a safety award for maintaining an accidentfree record.

- Recognized for outstanding performance and contributions to the team.

- Honored with a certification for excellence in Flying Shear Operations.

- Received a recognition for innovation in shear optimization.

Certificates

- Flying Shear Operator Certification

- CNC Operator Certification

- Quality Control Certification

- Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flying Shear Operator

- Emphasize your experience in operating flying shears and cutting metal sheets to precise dimensions.

- Highlight your skills in maintaining and calibrating flying shear equipment to ensure optimal performance.

- Showcase your knowledge of advanced shearing techniques and your ability to create complex shapes and angles.

- Demonstrate your commitment to safety by mentioning your experience in developing and implementing safety protocols.

Essential Experience Highlights for a Strong Flying Shear Operator Resume

- Operated flying shear to cut metal sheets to precise dimensions, reducing material waste by 15%.

- Maintained and calibrated flying shear equipment, ensuring optimal performance and minimizing downtime.

- Utilized advanced shearing techniques to create complex shapes and angles, meeting tight customer specifications.

- Developed and implemented safety protocols to mitigate risks associated with flying shear operation.

- Collaborated with engineers to optimize shearing process, resulting in increased production efficiency.

- Troubleshooted and resolved operational issues promptly, minimizing production delays.

- Adhered to ISO 9001 quality standards, ensuring consistently high-quality shearing results.

Frequently Asked Questions (FAQ’s) For Flying Shear Operator

What is a flying shear operator?

A Flying Shear Operator is a professional who operates a flying shear machine to cut metal sheets to precise dimensions and specifications. They are responsible for setting up and calibrating the machine, as well as maintaining and troubleshooting any issues that may arise.

What are the key skills required for a flying shear operator?

Key skills for a flying shear operator include the ability to operate a flying shear machine, set up and calibrate the machine, maintain and troubleshoot the machine, and follow safety protocols.

What are the career prospects for a flying shear operator?

Flying shear operators can advance to positions such as supervisor, production manager, or quality control manager. With additional training and experience, they can also become engineers or technical specialists.

What is the average salary for a flying shear operator?

The average salary for a flying shear operator varies depending on experience, location, and company size. According to Indeed, the average salary for a flying shear operator in the United States is $24.50 per hour.

What are the working conditions for a flying shear operator?

Flying shear operators typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes. They must also be able to stand for long periods of time and lift heavy objects.

What are the benefits of working as a flying shear operator?

Benefits of working as a flying shear operator include competitive salaries, opportunities for advancement, and the chance to work with cutting-edge technology.

What are the challenges of working as a flying shear operator?

Challenges of working as a flying shear operator include the need to work in a fast-paced environment, the potential for repetitive tasks, and the exposure to noise and dust.