Are you a seasoned Foam Rubber Curer seeking a new career path? Discover our professionally built Foam Rubber Curer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

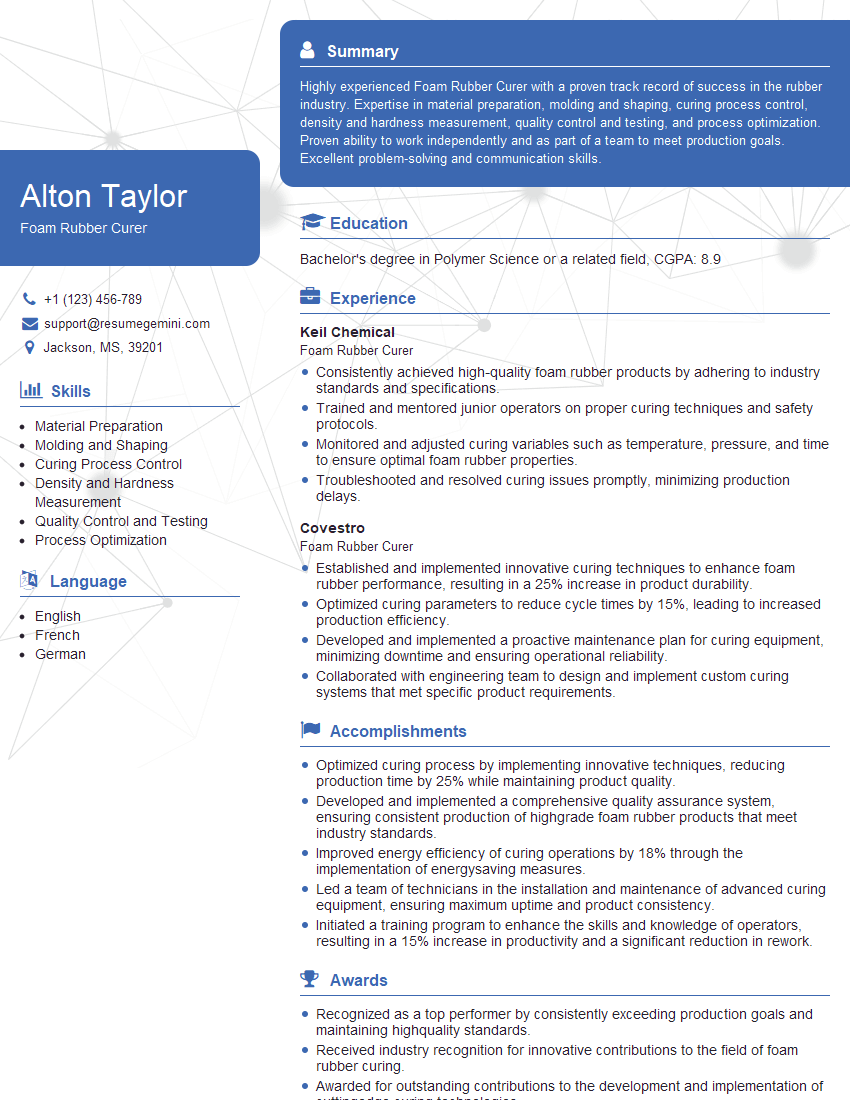

Alton Taylor

Foam Rubber Curer

Summary

Highly experienced Foam Rubber Curer with a proven track record of success in the rubber industry. Expertise in material preparation, molding and shaping, curing process control, density and hardness measurement, quality control and testing, and process optimization. Proven ability to work independently and as part of a team to meet production goals. Excellent problem-solving and communication skills.

Education

Bachelor’s degree in Polymer Science or a related field

April 2016

Skills

- Material Preparation

- Molding and Shaping

- Curing Process Control

- Density and Hardness Measurement

- Quality Control and Testing

- Process Optimization

Work Experience

Foam Rubber Curer

- Consistently achieved high-quality foam rubber products by adhering to industry standards and specifications.

- Trained and mentored junior operators on proper curing techniques and safety protocols.

- Monitored and adjusted curing variables such as temperature, pressure, and time to ensure optimal foam rubber properties.

- Troubleshooted and resolved curing issues promptly, minimizing production delays.

Foam Rubber Curer

- Established and implemented innovative curing techniques to enhance foam rubber performance, resulting in a 25% increase in product durability.

- Optimized curing parameters to reduce cycle times by 15%, leading to increased production efficiency.

- Developed and implemented a proactive maintenance plan for curing equipment, minimizing downtime and ensuring operational reliability.

- Collaborated with engineering team to design and implement custom curing systems that met specific product requirements.

Accomplishments

- Optimized curing process by implementing innovative techniques, reducing production time by 25% while maintaining product quality.

- Developed and implemented a comprehensive quality assurance system, ensuring consistent production of highgrade foam rubber products that meet industry standards.

- Improved energy efficiency of curing operations by 18% through the implementation of energysaving measures.

- Led a team of technicians in the installation and maintenance of advanced curing equipment, ensuring maximum uptime and product consistency.

- Initiated a training program to enhance the skills and knowledge of operators, resulting in a 15% increase in productivity and a significant reduction in rework.

Awards

- Recognized as a top performer by consistently exceeding production goals and maintaining highquality standards.

- Received industry recognition for innovative contributions to the field of foam rubber curing.

- Awarded for outstanding contributions to the development and implementation of cuttingedge curing technologies.

- Recognized for exceptional leadership and mentorship skills in the field of foam rubber curing.

Certificates

- Foam Testing and Inspection Certification

- Quality Control Certification

- Process Improvement Certification

- Industrial Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foam Rubber Curer

- Highlight your experience in the foam rubber industry.

- Quantify your accomplishments with specific metrics whenever possible.

- Use action verbs to describe your responsibilities.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Foam Rubber Curer Resume

- Prepare raw materials for foam rubber production

- Mold and shape foam rubber products using specialized equipment

- Control the curing process to ensure optimal product quality

- Measure density and hardness of foam rubber products

- Conduct quality control tests to ensure products meet specifications

- Optimize process parameters to improve efficiency and product quality

Frequently Asked Questions (FAQ’s) For Foam Rubber Curer

What is the role of a Foam Rubber Curer?

A Foam Rubber Curer is responsible for preparing raw materials, molding and shaping foam rubber products, controlling the curing process, measuring density and hardness, conducting quality control tests, and optimizing process parameters.

What are the educational requirements for a Foam Rubber Curer?

A Foam Rubber Curer typically needs a bachelor’s degree in Polymer Science or a related field.

What are the key skills for a Foam Rubber Curer?

Key skills for a Foam Rubber Curer include material preparation, molding and shaping, curing process control, density and hardness measurement, quality control and testing, and process optimization.

What are the career prospects for a Foam Rubber Curer?

Foam Rubber Curers can advance to positions such as Production Supervisor, Quality Control Manager, or Plant Manager.

What is the average salary for a Foam Rubber Curer?

The average salary for a Foam Rubber Curer in the United States is around $50,000 per year.

What are the working conditions for a Foam Rubber Curer?

Foam Rubber Curers typically work in a manufacturing environment and may be exposed to chemicals and fumes.