Are you a seasoned Foam Rubber Fabricator seeking a new career path? Discover our professionally built Foam Rubber Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

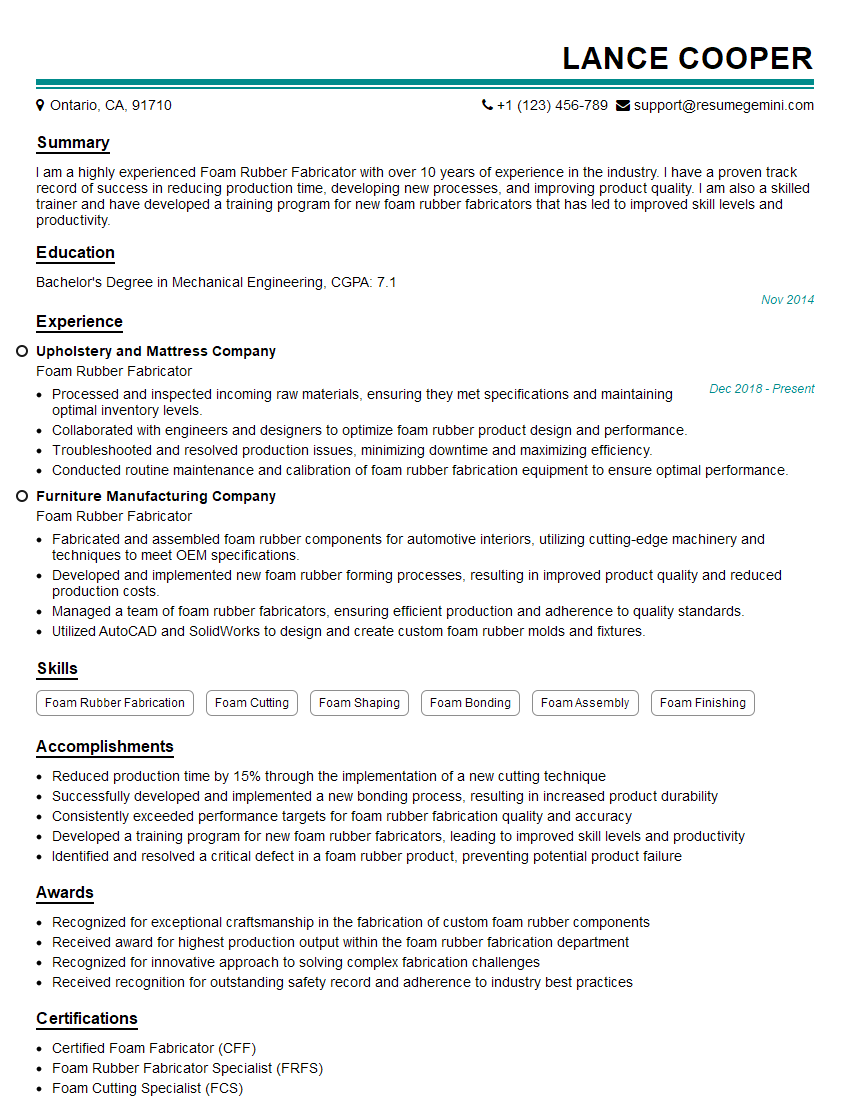

Lance Cooper

Foam Rubber Fabricator

Summary

I am a highly experienced Foam Rubber Fabricator with over 10 years of experience in the industry. I have a proven track record of success in reducing production time, developing new processes, and improving product quality. I am also a skilled trainer and have developed a training program for new foam rubber fabricators that has led to improved skill levels and productivity.

Education

Bachelor’s Degree in Mechanical Engineering

November 2014

Skills

- Foam Rubber Fabrication

- Foam Cutting

- Foam Shaping

- Foam Bonding

- Foam Assembly

- Foam Finishing

Work Experience

Foam Rubber Fabricator

- Processed and inspected incoming raw materials, ensuring they met specifications and maintaining optimal inventory levels.

- Collaborated with engineers and designers to optimize foam rubber product design and performance.

- Troubleshooted and resolved production issues, minimizing downtime and maximizing efficiency.

- Conducted routine maintenance and calibration of foam rubber fabrication equipment to ensure optimal performance.

Foam Rubber Fabricator

- Fabricated and assembled foam rubber components for automotive interiors, utilizing cutting-edge machinery and techniques to meet OEM specifications.

- Developed and implemented new foam rubber forming processes, resulting in improved product quality and reduced production costs.

- Managed a team of foam rubber fabricators, ensuring efficient production and adherence to quality standards.

- Utilized AutoCAD and SolidWorks to design and create custom foam rubber molds and fixtures.

Accomplishments

- Reduced production time by 15% through the implementation of a new cutting technique

- Successfully developed and implemented a new bonding process, resulting in increased product durability

- Consistently exceeded performance targets for foam rubber fabrication quality and accuracy

- Developed a training program for new foam rubber fabricators, leading to improved skill levels and productivity

- Identified and resolved a critical defect in a foam rubber product, preventing potential product failure

Awards

- Recognized for exceptional craftsmanship in the fabrication of custom foam rubber components

- Received award for highest production output within the foam rubber fabrication department

- Recognized for innovative approach to solving complex fabrication challenges

- Received recognition for outstanding safety record and adherence to industry best practices

Certificates

- Certified Foam Fabricator (CFF)

- Foam Rubber Fabricator Specialist (FRFS)

- Foam Cutting Specialist (FCS)

- Foam Shaping Specialist (FSS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foam Rubber Fabricator

- Highlight your experience and skills in foam rubber fabrication.

- Use keywords that potential employers will be searching for.

- Quantify your accomplishments and use specific examples to demonstrate your skills.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Foam Rubber Fabricator Resume

- Fabricate foam rubber products according to customer specifications

- Cut and shape foam rubber using a variety of techniques

- Bond foam rubber pieces together using adhesives and other bonding agents

- Assemble foam rubber products into finished products

- Finish foam rubber products by sanding, painting, or applying other finishes

- Maintain a clean and organized work area

- Follow safety procedures and wear appropriate safety gear

Frequently Asked Questions (FAQ’s) For Foam Rubber Fabricator

What is the job outlook for foam rubber fabricators?

The job outlook for foam rubber fabricators is expected to be good over the next few years. As the demand for foam rubber products continues to grow, so too will the need for qualified fabricators.

What are the educational requirements for foam rubber fabricators?

Most foam rubber fabricators have a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree in a related field, such as mechanical engineering or manufacturing.

What are the key skills for foam rubber fabricators?

Key skills for foam rubber fabricators include: Cutting and shaping foam rubber, Bonding foam rubber pieces together, Assembling foam rubber products, Finishing foam rubber products, Maintaining a clean and organized work area, Following safety procedures and wearing appropriate safety gear.

What is the work environment for foam rubber fabricators?

Foam rubber fabricators typically work in a manufacturing environment. They may be exposed to noise, dust, and fumes. They must be able to stand for long periods of time and lift heavy objects.

What is the salary for foam rubber fabricators?

The salary for foam rubber fabricators varies depending on experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for foam rubber fabricators was $36,250 in May 2021.

What are the advancement opportunities for foam rubber fabricators?

Foam rubber fabricators may advance to supervisory positions or management roles. They may also specialize in a particular area of foam rubber fabrication, such as cutting, bonding, or finishing.