Are you a seasoned Forge Press Operator seeking a new career path? Discover our professionally built Forge Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

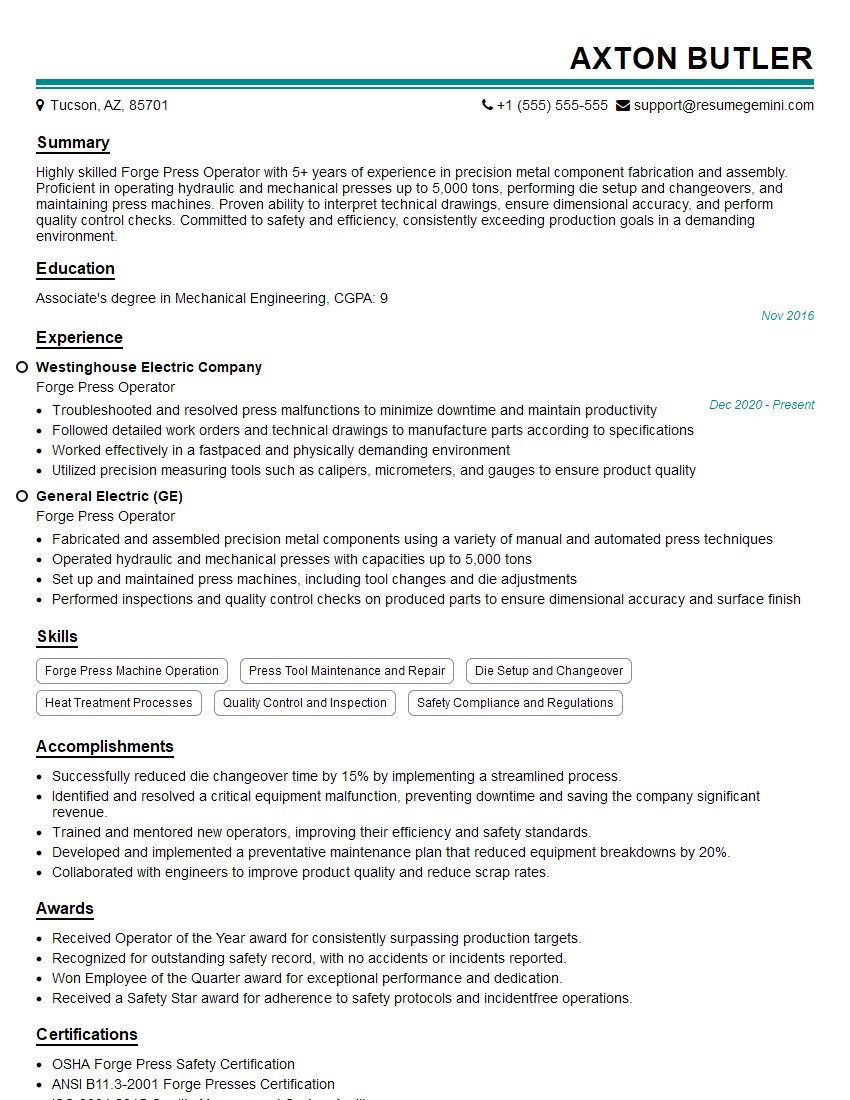

Axton Butler

Forge Press Operator

Summary

Highly skilled Forge Press Operator with 5+ years of experience in precision metal component fabrication and assembly. Proficient in operating hydraulic and mechanical presses up to 5,000 tons, performing die setup and changeovers, and maintaining press machines. Proven ability to interpret technical drawings, ensure dimensional accuracy, and perform quality control checks. Committed to safety and efficiency, consistently exceeding production goals in a demanding environment.

Education

Associate’s degree in Mechanical Engineering

November 2016

Skills

- Forge Press Machine Operation

- Press Tool Maintenance and Repair

- Die Setup and Changeover

- Heat Treatment Processes

- Quality Control and Inspection

- Safety Compliance and Regulations

Work Experience

Forge Press Operator

- Troubleshooted and resolved press malfunctions to minimize downtime and maintain productivity

- Followed detailed work orders and technical drawings to manufacture parts according to specifications

- Worked effectively in a fastpaced and physically demanding environment

- Utilized precision measuring tools such as calipers, micrometers, and gauges to ensure product quality

Forge Press Operator

- Fabricated and assembled precision metal components using a variety of manual and automated press techniques

- Operated hydraulic and mechanical presses with capacities up to 5,000 tons

- Set up and maintained press machines, including tool changes and die adjustments

- Performed inspections and quality control checks on produced parts to ensure dimensional accuracy and surface finish

Accomplishments

- Successfully reduced die changeover time by 15% by implementing a streamlined process.

- Identified and resolved a critical equipment malfunction, preventing downtime and saving the company significant revenue.

- Trained and mentored new operators, improving their efficiency and safety standards.

- Developed and implemented a preventative maintenance plan that reduced equipment breakdowns by 20%.

- Collaborated with engineers to improve product quality and reduce scrap rates.

Awards

- Received Operator of the Year award for consistently surpassing production targets.

- Recognized for outstanding safety record, with no accidents or incidents reported.

- Won Employee of the Quarter award for exceptional performance and dedication.

- Received a Safety Star award for adherence to safety protocols and incidentfree operations.

Certificates

- OSHA Forge Press Safety Certification

- ANSI B11.3-2001 Forge Presses Certification

- ISO 9001:2015 Quality Management System Auditor

- IATF 16949:2016 Automotive Quality Management System Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forge Press Operator

- Highlight your experience and skills in press machine operation, tool maintenance, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each job application, emphasizing the skills and experience most relevant to the specific role.

- Proofread your resume carefully before submitting it to ensure that there are no errors.

Essential Experience Highlights for a Strong Forge Press Operator Resume

- Fabricated and assembled precision metal components using various manual and automated press techniques.

- Operated hydraulic and mechanical presses with capacities up to 5,000 tons to forge and shape metal components.

- Set up and maintained press machines, including tool changes and die adjustments, to ensure optimal performance.

- Performed inspections and quality control checks on produced parts to guarantee dimensional accuracy and surface finish.

- Troubleshooted and resolved press malfunctions to minimize downtime and maintain productivity.

- Followed detailed work orders and technical drawings to manufacture parts according to specifications.

- Worked effectively in a fast-paced and physically demanding environment.

Frequently Asked Questions (FAQ’s) For Forge Press Operator

What is the role of a Forge Press Operator?

A Forge Press Operator is responsible for operating and maintaining forge presses to shape and form metal components. They set up and adjust dies, perform quality control checks, and troubleshoot and resolve press malfunctions to ensure efficient production.

What are the essential skills required to be a Forge Press Operator?

Essential skills include proficiency in operating forge presses, tool maintenance, die setup and changeover, quality control and inspection, and adherence to safety regulations.

What industries employ Forge Press Operators?

Forge Press Operators are employed in industries such as automotive, aerospace, construction, and manufacturing.

What is the average salary for a Forge Press Operator?

The average salary for a Forge Press Operator can vary depending on experience, location, and industry. According to Salary.com, the average salary range is between $30,000 to $50,000 per year.

Is the job of a Forge Press Operator physically demanding?

Yes, the job of a Forge Press Operator can be physically demanding. It involves working in a fast-paced and physically demanding environment, often requiring heavy lifting and standing for long periods.

What are the advancement opportunities for a Forge Press Operator?

Advancement opportunities may include promotions to lead operator, supervisor, or plant manager roles. With additional training or education, Forge Press Operators can also transition into other related fields such as tool and die making or engineering.

What safety precautions are important for Forge Press Operators to follow?

Important safety precautions include wearing appropriate personal protective equipment such as gloves, safety glasses, and earplugs, following lockout/tagout procedures when performing maintenance tasks, and being aware of potential hazards such as hot metal and moving machinery.