Are you a seasoned Forge Shop Machine Repairer seeking a new career path? Discover our professionally built Forge Shop Machine Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

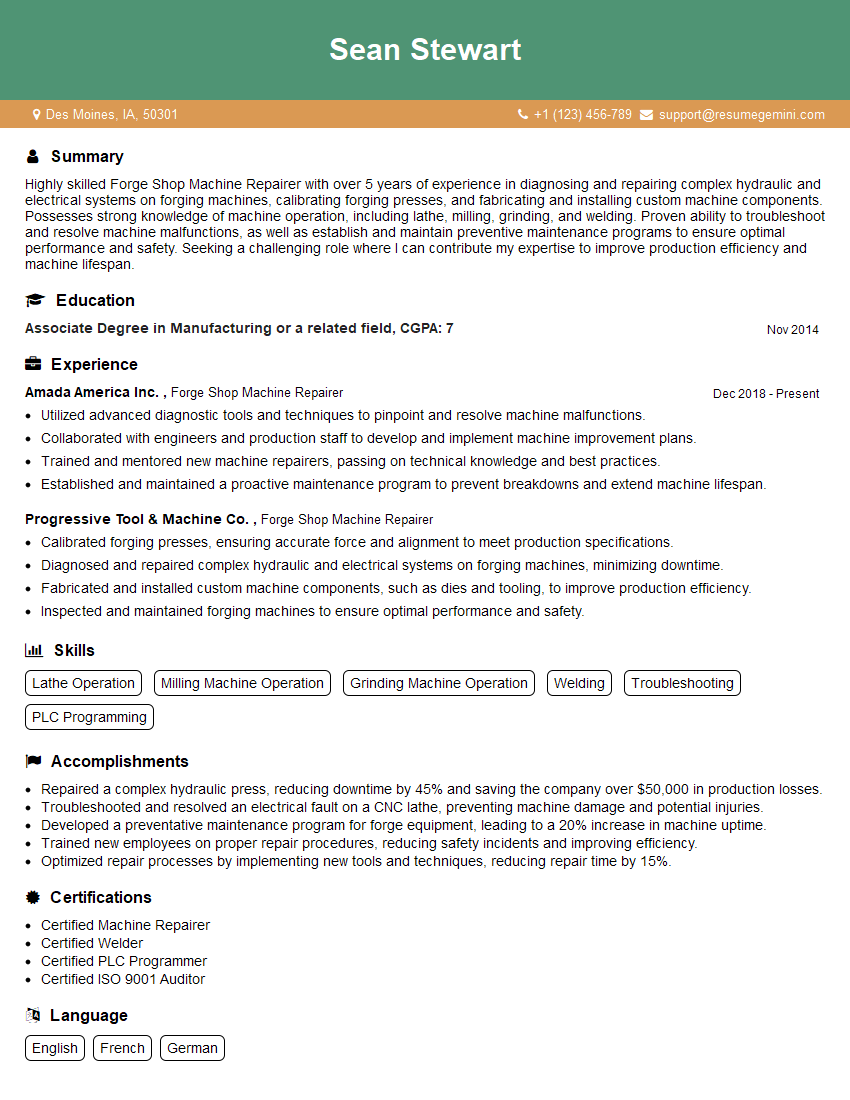

Sean Stewart

Forge Shop Machine Repairer

Summary

Highly skilled Forge Shop Machine Repairer with over 5 years of experience in diagnosing and repairing complex hydraulic and electrical systems on forging machines, calibrating forging presses, and fabricating and installing custom machine components. Possesses strong knowledge of machine operation, including lathe, milling, grinding, and welding. Proven ability to troubleshoot and resolve machine malfunctions, as well as establish and maintain preventive maintenance programs to ensure optimal performance and safety. Seeking a challenging role where I can contribute my expertise to improve production efficiency and machine lifespan.

Education

Associate Degree in Manufacturing or a related field

November 2014

Skills

- Lathe Operation

- Milling Machine Operation

- Grinding Machine Operation

- Welding

- Troubleshooting

- PLC Programming

Work Experience

Forge Shop Machine Repairer

- Utilized advanced diagnostic tools and techniques to pinpoint and resolve machine malfunctions.

- Collaborated with engineers and production staff to develop and implement machine improvement plans.

- Trained and mentored new machine repairers, passing on technical knowledge and best practices.

- Established and maintained a proactive maintenance program to prevent breakdowns and extend machine lifespan.

Forge Shop Machine Repairer

- Calibrated forging presses, ensuring accurate force and alignment to meet production specifications.

- Diagnosed and repaired complex hydraulic and electrical systems on forging machines, minimizing downtime.

- Fabricated and installed custom machine components, such as dies and tooling, to improve production efficiency.

- Inspected and maintained forging machines to ensure optimal performance and safety.

Accomplishments

- Repaired a complex hydraulic press, reducing downtime by 45% and saving the company over $50,000 in production losses.

- Troubleshooted and resolved an electrical fault on a CNC lathe, preventing machine damage and potential injuries.

- Developed a preventative maintenance program for forge equipment, leading to a 20% increase in machine uptime.

- Trained new employees on proper repair procedures, reducing safety incidents and improving efficiency.

- Optimized repair processes by implementing new tools and techniques, reducing repair time by 15%.

Certificates

- Certified Machine Repairer

- Certified Welder

- Certified PLC Programmer

- Certified ISO 9001 Auditor

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forge Shop Machine Repairer

- Highlight your experience in diagnosing and repairing complex hydraulic and electrical systems.

- Quantify your accomplishments with specific examples of how you improved production efficiency or reduced downtime.

- Showcase your knowledge of machine operation and fabrication techniques, including lathe, milling, grinding, and welding.

- Emphasize your ability to work independently and as part of a team to troubleshoot and resolve machine issues.

Essential Experience Highlights for a Strong Forge Shop Machine Repairer Resume

- Calibrating and maintaining forging presses for accurate force and alignment to meet production specifications.

- Diagnosing and repairing complex hydraulic and electrical systems on forging machines.

- Fabricating and installing custom machine components, such as dies and tooling, to enhance production efficiency.

- Inspecting and maintaining forging machines to ensure optimal performance, safety, and compliance with industry standards.

- Utilizing advanced diagnostic tools and techniques to pinpoint and resolve machine malfunctions, minimizing downtime.

- Collaborating with engineers and production staff to develop and implement machine improvement plans, optimizing production processes.

Frequently Asked Questions (FAQ’s) For Forge Shop Machine Repairer

What are the primary responsibilities of a Forge Shop Machine Repairer?

Forge Shop Machine Repairers are responsible for maintaining and repairing forging machines, including diagnosing and fixing hydraulic and electrical systems, calibrating presses, and fabricating custom machine components.

What skills are essential for a Forge Shop Machine Repairer?

Essential skills include knowledge of machine operation, hydraulics, electrical systems, welding, and troubleshooting techniques.

What type of education or training is required to become a Forge Shop Machine Repairer?

An Associate Degree in Manufacturing or a related field is typically required, along with hands-on experience in machine repair.

What are the career prospects for Forge Shop Machine Repairers?

With the increasing demand for skilled tradespeople, Forge Shop Machine Repairers have good career prospects, with opportunities for advancement to supervisory or management roles.

What is the average salary for a Forge Shop Machine Repairer?

The average salary for a Forge Shop Machine Repairer varies depending on experience, location, and industry, but typically ranges from $25,000 to $60,000 per year.

What are the key challenges faced by Forge Shop Machine Repairers?

Forge Shop Machine Repairers often work in demanding environments with heavy machinery, requiring physical strength and attention to safety.