Are you a seasoned Forgesmith seeking a new career path? Discover our professionally built Forgesmith Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

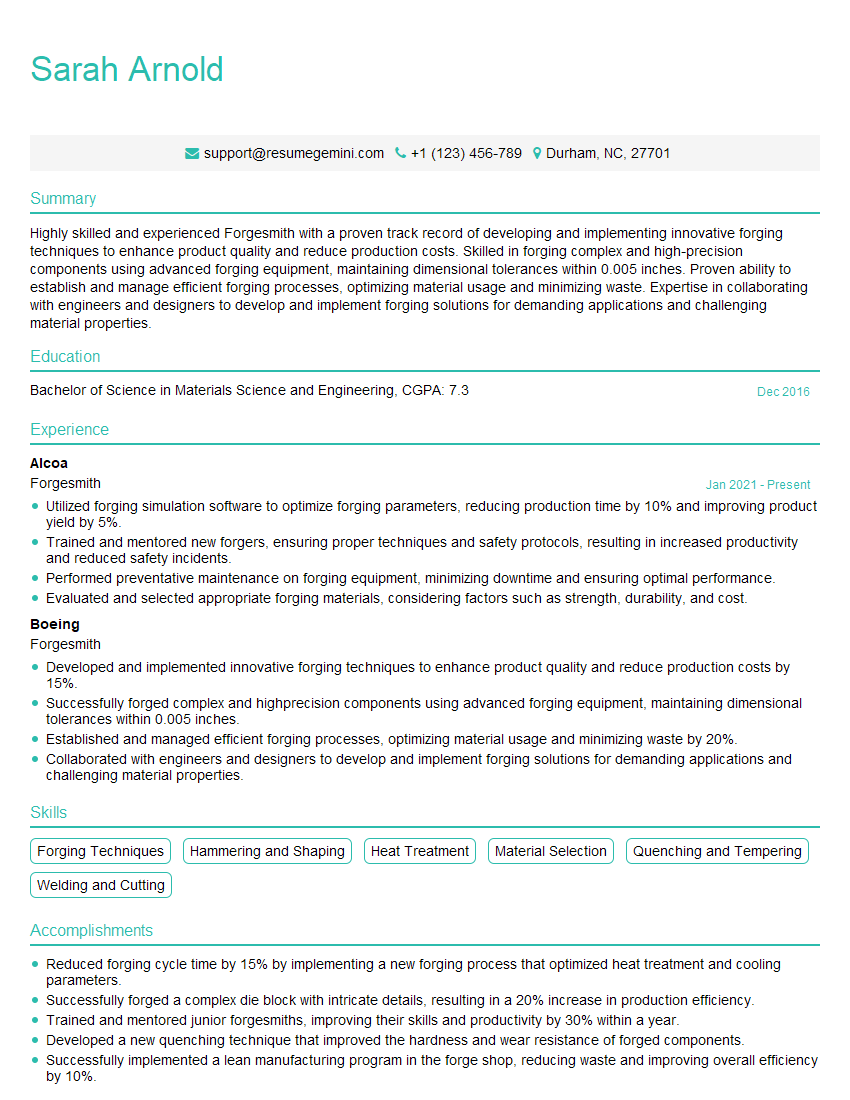

Sarah Arnold

Forgesmith

Summary

Highly skilled and experienced Forgesmith with a proven track record of developing and implementing innovative forging techniques to enhance product quality and reduce production costs. Skilled in forging complex and high-precision components using advanced forging equipment, maintaining dimensional tolerances within 0.005 inches. Proven ability to establish and manage efficient forging processes, optimizing material usage and minimizing waste. Expertise in collaborating with engineers and designers to develop and implement forging solutions for demanding applications and challenging material properties.

Education

Bachelor of Science in Materials Science and Engineering

December 2016

Skills

- Forging Techniques

- Hammering and Shaping

- Heat Treatment

- Material Selection

- Quenching and Tempering

- Welding and Cutting

Work Experience

Forgesmith

- Utilized forging simulation software to optimize forging parameters, reducing production time by 10% and improving product yield by 5%.

- Trained and mentored new forgers, ensuring proper techniques and safety protocols, resulting in increased productivity and reduced safety incidents.

- Performed preventative maintenance on forging equipment, minimizing downtime and ensuring optimal performance.

- Evaluated and selected appropriate forging materials, considering factors such as strength, durability, and cost.

Forgesmith

- Developed and implemented innovative forging techniques to enhance product quality and reduce production costs by 15%.

- Successfully forged complex and highprecision components using advanced forging equipment, maintaining dimensional tolerances within 0.005 inches.

- Established and managed efficient forging processes, optimizing material usage and minimizing waste by 20%.

- Collaborated with engineers and designers to develop and implement forging solutions for demanding applications and challenging material properties.

Accomplishments

- Reduced forging cycle time by 15% by implementing a new forging process that optimized heat treatment and cooling parameters.

- Successfully forged a complex die block with intricate details, resulting in a 20% increase in production efficiency.

- Trained and mentored junior forgesmiths, improving their skills and productivity by 30% within a year.

- Developed a new quenching technique that improved the hardness and wear resistance of forged components.

- Successfully implemented a lean manufacturing program in the forge shop, reducing waste and improving overall efficiency by 10%.

Awards

- Received the Gold Award for Outstanding Achievement in Forging at the National Forge Association Annual Conference.

- Recognized as one of the Top 10 Forgesmiths in the industry by Forge Magazine for exceptional craftsmanship and technical innovation.

- Won the Silver Medal in the International Forging Competition for excellence in forging technique and quality.

- Received the Employee of the Quarter Award for consistently producing exceptional forgings that met or exceeded customer specifications.

Certificates

- Certified Welding Inspector (CWI)

- Certified Weld Tester (CWT)

- Certified Quality Control Inspector (CQI)

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forgesmith

- Highlight your experience in developing and implementing innovative forging techniques.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your ability to work collaboratively with engineers and designers.

- Demonstrate your knowledge of forging simulation software and other relevant technologies.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Forgesmith Resume

- Developed and implemented innovative forging techniques to enhance product quality and reduce production costs by 15%.

- Successfully forged complex and high-precision components using advanced forging equipment, maintaining dimensional tolerances within 0.005 inches.

- Established and managed efficient forging processes, optimizing material usage and minimizing waste by 20%.

- Collaborated with engineers and designers to develop and implement forging solutions for demanding applications and challenging material properties.

- Utilized forging simulation software to optimize forging parameters, reducing production time by 10% and improving product yield by 5%.

- Trained and mentored new forgers, ensuring proper techniques and safety protocols, resulting in increased productivity and reduced safety incidents.

Frequently Asked Questions (FAQ’s) For Forgesmith

What are the key skills required to be a successful Forgesmith?

The key skills required to be a successful Forgesmith include forging techniques, hammering and shaping, heat treatment, material selection, quenching and tempering, welding and cutting.

What are the typical job responsibilities of a Forgesmith?

The typical job responsibilities of a Forgesmith include developing and implementing forging techniques, forging complex and high-precision components, establishing and managing efficient forging processes, collaborating with engineers and designers, and training and mentoring new forgers.

What are the career prospects for Forgesmiths?

The career prospects for Forgesmiths are generally positive. The demand for skilled Forgesmiths is expected to remain high in the coming years due to the increasing use of forged components in various industries.

What are the educational requirements to become a Forgesmith?

The educational requirements to become a Forgesmith typically include a high school diploma or equivalent, as well as on-the-job training or an apprenticeship program.

What are the salary expectations for Forgesmiths?

The salary expectations for Forgesmiths vary depending on their experience, skills, and location. According to Indeed, the average salary for a Forgesmith in the United States is $65,000 per year.

What are the working conditions for Forgesmiths?

Forgesmiths typically work in hot and noisy environments. They may also be exposed to fumes and dust.

What are the safety precautions that Forgesmiths must take?

Forgesmiths must take safety precautions to protect themselves from burns, cuts, and other injuries. These precautions include wearing appropriate protective clothing and equipment, and following proper safety procedures.

What are the challenges that Forgesmiths face?

Forgesmiths face a number of challenges, including the need to work in hot and noisy environments, the need to be exposed to fumes and dust, and the need to take safety precautions to protect themselves from burns, cuts, and other injuries.