Are you a seasoned Foundry Helper seeking a new career path? Discover our professionally built Foundry Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

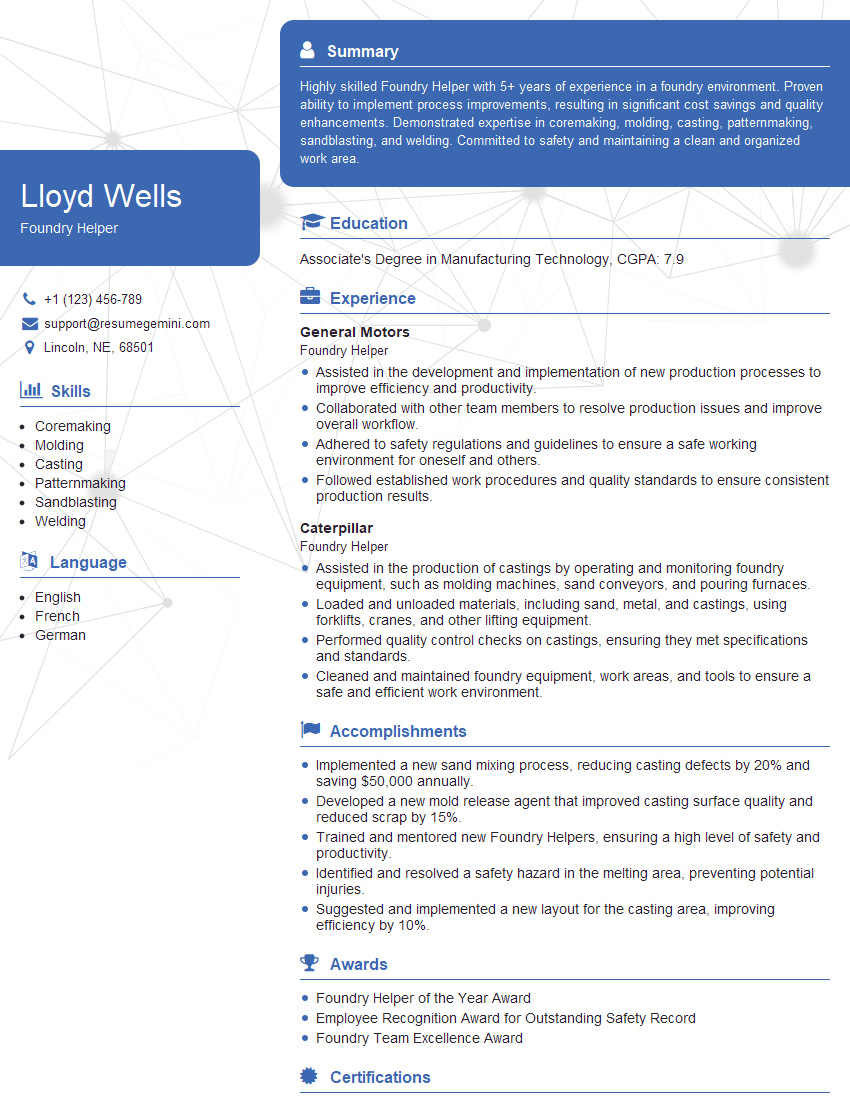

Lloyd Wells

Foundry Helper

Summary

Highly skilled Foundry Helper with 5+ years of experience in a foundry environment. Proven ability to implement process improvements, resulting in significant cost savings and quality enhancements. Demonstrated expertise in coremaking, molding, casting, patternmaking, sandblasting, and welding. Committed to safety and maintaining a clean and organized work area.

Education

Associate’s Degree in Manufacturing Technology

July 2018

Skills

- Coremaking

- Molding

- Casting

- Patternmaking

- Sandblasting

- Welding

Work Experience

Foundry Helper

- Assisted in the development and implementation of new production processes to improve efficiency and productivity.

- Collaborated with other team members to resolve production issues and improve overall workflow.

- Adhered to safety regulations and guidelines to ensure a safe working environment for oneself and others.

- Followed established work procedures and quality standards to ensure consistent production results.

Foundry Helper

- Assisted in the production of castings by operating and monitoring foundry equipment, such as molding machines, sand conveyors, and pouring furnaces.

- Loaded and unloaded materials, including sand, metal, and castings, using forklifts, cranes, and other lifting equipment.

- Performed quality control checks on castings, ensuring they met specifications and standards.

- Cleaned and maintained foundry equipment, work areas, and tools to ensure a safe and efficient work environment.

Accomplishments

- Implemented a new sand mixing process, reducing casting defects by 20% and saving $50,000 annually.

- Developed a new mold release agent that improved casting surface quality and reduced scrap by 15%.

- Trained and mentored new Foundry Helpers, ensuring a high level of safety and productivity.

- Identified and resolved a safety hazard in the melting area, preventing potential injuries.

- Suggested and implemented a new layout for the casting area, improving efficiency by 10%.

Awards

- Foundry Helper of the Year Award

- Employee Recognition Award for Outstanding Safety Record

- Foundry Team Excellence Award

Certificates

- OSHA 30Hour Safety Training

- Forklift Operator Certification

- Crane Operator Certification

- Foundry Safety and Health Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foundry Helper

Highlight relevant experience:

Specifically mention any foundry-related experience, such as coremaking, molding, or casting, that you have.Quantify your accomplishments:

Use numbers to demonstrate the impact of your work, such as the percentage reduction in casting defects or the amount of money saved.Emphasize safety:

Foundry work can be hazardous, so highlight your commitment to safety and your experience in maintaining a safe work environment.Include keywords:

Use industry-specific keywords throughout your resume, such as coremaking, molding, casting, and quality control.

Essential Experience Highlights for a Strong Foundry Helper Resume

- Assisted in the preparation and operation of foundry equipment, including coremaking machines, molding machines, and casting furnaces.

- Monitored and controlled the flow of materials and equipment throughout the foundry, ensuring smooth and efficient operations.

- Performed quality control checks on castings, identifying and addressing defects to maintain high-quality standards.

- Participated in the maintenance and repair of foundry equipment, ensuring optimal performance and minimizing downtime.

- Complied with all safety regulations and procedures, maintaining a safe and healthy work environment.

- Collaborated with other foundry personnel to ensure efficient and productive operations.

Frequently Asked Questions (FAQ’s) For Foundry Helper

What is the role of a Foundry Helper?

A Foundry Helper assists in the operation of a foundry, performing tasks such as preparing and operating equipment, monitoring materials flow, and performing quality control checks.

What skills are required to be a Foundry Helper?

Foundry Helpers typically have experience in coremaking, molding, casting, patternmaking, sandblasting, and welding. They should also be familiar with safety regulations and procedures.

What are the benefits of working as a Foundry Helper?

Foundry Helpers can enjoy competitive salaries and benefits, as well as the opportunity to work in a challenging and rewarding environment. This role is also a great starting point for a career in the manufacturing industry.

What are the challenges of working as a Foundry Helper?

Foundry work can be physically demanding and hazardous, so Foundry Helpers must be prepared for a physically demanding job and must take appropriate safety precautions.

What is the career path for a Foundry Helper?

Foundry Helpers can advance to positions such as Foundry Operator, Foundry Technician, or Foundry Supervisor. With additional education and training, they may also qualify for management positions.

What is the job outlook for Foundry Helpers?

The job outlook for Foundry Helpers is expected to be good in the coming years, as the manufacturing industry continues to grow.

What are the earning potential of Foundry Helpers?

Foundry Helpers can earn competitive salaries, with the median annual salary being around $40,000.

What are the working conditions for Foundry Helpers?

Foundry Helpers typically work in a hot, noisy environment, and may be exposed to hazardous materials. They must wear appropriate protective gear and follow safety procedures to minimize risks.