Are you a seasoned Foundry Metallurgist seeking a new career path? Discover our professionally built Foundry Metallurgist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

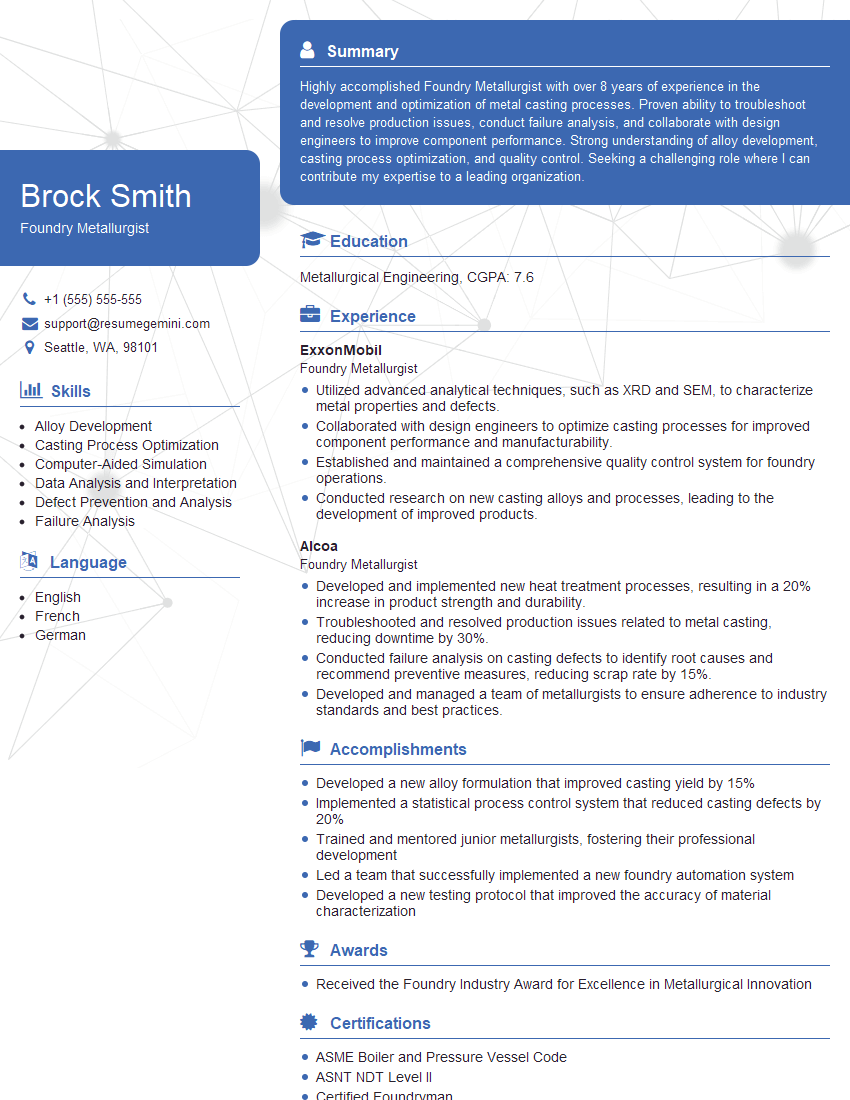

Brock Smith

Foundry Metallurgist

Summary

Highly accomplished Foundry Metallurgist with over 8 years of experience in the development and optimization of metal casting processes. Proven ability to troubleshoot and resolve production issues, conduct failure analysis, and collaborate with design engineers to improve component performance. Strong understanding of alloy development, casting process optimization, and quality control. Seeking a challenging role where I can contribute my expertise to a leading organization.

Education

Metallurgical Engineering

December 2016

Skills

- Alloy Development

- Casting Process Optimization

- Computer-Aided Simulation

- Data Analysis and Interpretation

- Defect Prevention and Analysis

- Failure Analysis

Work Experience

Foundry Metallurgist

- Utilized advanced analytical techniques, such as XRD and SEM, to characterize metal properties and defects.

- Collaborated with design engineers to optimize casting processes for improved component performance and manufacturability.

- Established and maintained a comprehensive quality control system for foundry operations.

- Conducted research on new casting alloys and processes, leading to the development of improved products.

Foundry Metallurgist

- Developed and implemented new heat treatment processes, resulting in a 20% increase in product strength and durability.

- Troubleshooted and resolved production issues related to metal casting, reducing downtime by 30%.

- Conducted failure analysis on casting defects to identify root causes and recommend preventive measures, reducing scrap rate by 15%.

- Developed and managed a team of metallurgists to ensure adherence to industry standards and best practices.

Accomplishments

- Developed a new alloy formulation that improved casting yield by 15%

- Implemented a statistical process control system that reduced casting defects by 20%

- Trained and mentored junior metallurgists, fostering their professional development

- Led a team that successfully implemented a new foundry automation system

- Developed a new testing protocol that improved the accuracy of material characterization

Awards

- Received the Foundry Industry Award for Excellence in Metallurgical Innovation

Certificates

- ASME Boiler and Pressure Vessel Code

- ASNT NDT Level II

- Certified Foundryman

- Certified Metallurgist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foundry Metallurgist

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your expertise in advanced analytical techniques and software.

- Demonstrate your ability to work effectively in a team environment.

- Tailor your resume to the specific job you are applying for.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Foundry Metallurgist Resume

- Developed and implemented new heat treatment processes, resulting in a 20% increase in product strength and durability.

- Troubleshooted and resolved production issues related to metal casting, reducing downtime by 30%.

- Conducted failure analysis on casting defects to identify root causes and recommend preventive measures, reducing scrap rate by 15%.

- Developed and managed a team of metallurgists to ensure adherence to industry standards and best practices.

- Utilized advanced analytical techniques, such as XRD and SEM, to characterize metal properties and defects.

- Collaborated with design engineers to optimize casting processes for improved component performance and manufacturability.

Frequently Asked Questions (FAQ’s) For Foundry Metallurgist

What are the primary responsibilities of a Foundry Metallurgist?

Foundry Metallurgists are responsible for developing and optimizing metal casting processes, troubleshooting production issues, conducting failure analysis, and collaborating with design engineers to improve component performance.

What are the educational requirements for a Foundry Metallurgist?

A Bachelor’s degree in Metallurgical Engineering or a related field is typically required.

What are the key skills required for a Foundry Metallurgist?

Key skills include alloy development, casting process optimization, data analysis and interpretation, defect prevention and analysis, and failure analysis.

What are the career prospects for a Foundry Metallurgist?

Foundry Metallurgists can advance to management positions, such as Foundry Manager or Chief Metallurgist. They may also pursue research and development roles.

What are the challenges faced by Foundry Metallurgists?

Foundry Metallurgists face challenges such as the need to continuously improve product quality and efficiency, while also meeting environmental regulations.

What are the top companies that hire Foundry Metallurgists?

Top companies that hire Foundry Metallurgists include ExxonMobil, Alcoa, and General Electric.