Are you a seasoned Foundry Process Engineer seeking a new career path? Discover our professionally built Foundry Process Engineer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

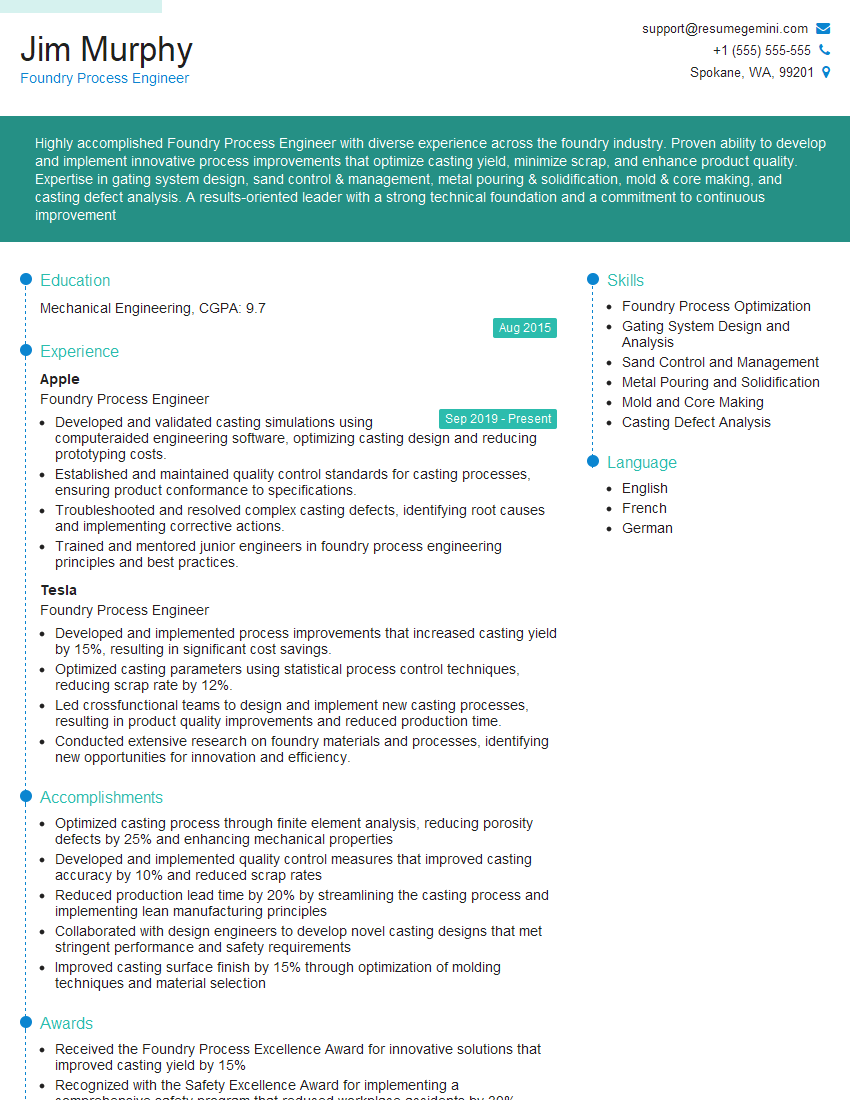

Jim Murphy

Foundry Process Engineer

Summary

Highly accomplished Foundry Process Engineer with diverse experience across the foundry industry. Proven ability to develop and implement innovative process improvements that optimize casting yield, minimize scrap, and enhance product quality. Expertise in gating system design, sand control & management, metal pouring & solidification, mold & core making, and casting defect analysis. A results-oriented leader with a strong technical foundation and a commitment to continuous improvement

Education

Mechanical Engineering

August 2015

Skills

- Foundry Process Optimization

- Gating System Design and Analysis

- Sand Control and Management

- Metal Pouring and Solidification

- Mold and Core Making

- Casting Defect Analysis

Work Experience

Foundry Process Engineer

- Developed and validated casting simulations using computeraided engineering software, optimizing casting design and reducing prototyping costs.

- Established and maintained quality control standards for casting processes, ensuring product conformance to specifications.

- Troubleshooted and resolved complex casting defects, identifying root causes and implementing corrective actions.

- Trained and mentored junior engineers in foundry process engineering principles and best practices.

Foundry Process Engineer

- Developed and implemented process improvements that increased casting yield by 15%, resulting in significant cost savings.

- Optimized casting parameters using statistical process control techniques, reducing scrap rate by 12%.

- Led crossfunctional teams to design and implement new casting processes, resulting in product quality improvements and reduced production time.

- Conducted extensive research on foundry materials and processes, identifying new opportunities for innovation and efficiency.

Accomplishments

- Optimized casting process through finite element analysis, reducing porosity defects by 25% and enhancing mechanical properties

- Developed and implemented quality control measures that improved casting accuracy by 10% and reduced scrap rates

- Reduced production lead time by 20% by streamlining the casting process and implementing lean manufacturing principles

- Collaborated with design engineers to develop novel casting designs that met stringent performance and safety requirements

- Improved casting surface finish by 15% through optimization of molding techniques and material selection

Awards

- Received the Foundry Process Excellence Award for innovative solutions that improved casting yield by 15%

- Recognized with the Safety Excellence Award for implementing a comprehensive safety program that reduced workplace accidents by 30%

- Awarded the Foundry Innovation Award for pioneering a new sand reclamation process that resulted in significant cost savings

- Received the Employee of the Year Award for exceptional contributions to the foundry process and innovation

Certificates

- Certified Foundry Engineer (CFE)

- Certified Manufacturing Engineer (CMfgE)

- ASQ Certified Quality Manager (CQM)

- ISO 9001 Quality Management System Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foundry Process Engineer

- Showcase your technical expertise in foundry processes and quality control methodologies

- Highlight your experience in developing and implementing process improvements that resulted in measurable outcomes

- Quantify your accomplishments with specific metrics and data to demonstrate your impact

- Emphasize your leadership qualities and ability to collaborate effectively in a team environment

- Demonstrate your commitment to continuous learning and professional development

Essential Experience Highlights for a Strong Foundry Process Engineer Resume

- Develop and implement process improvements to enhance casting yield, reduce scrap, and improve product quality

- Optimize casting parameters using statistical process control techniques to minimize defects and optimize production efficiency

- Lead cross-functional teams in designing and implementing new casting processes, resulting in product quality enhancements and reduced production times

- Conduct research on foundry materials and processes, identifying opportunities for innovation, efficiency, and cost savings

- Develop and validate casting simulations using computer-aided engineering software to optimize casting design and reduce prototyping costs

- Establish and maintain quality control standards for casting processes, ensuring product conformance to specifications

- Troubleshoot and resolve complex casting defects, identifying root causes and implementing corrective actions

Frequently Asked Questions (FAQ’s) For Foundry Process Engineer

What are the key responsibilities of a Foundry Process Engineer?

Foundry Process Engineers are responsible for developing, implementing, and optimizing casting processes to ensure the production of high-quality castings. They collaborate with cross-functional teams, conduct research, troubleshoot defects, and maintain quality control standards.

What are the essential skills for a successful Foundry Process Engineer?

Foundry Process Engineers require expertise in foundry processes, gating system design, sand control, metal pouring & solidification, mold & core making, casting defect analysis, and quality control methodologies.

What industries employ Foundry Process Engineers?

Foundry Process Engineers are employed in various industries, including automotive, aerospace, construction, energy, and manufacturing.

What are the career advancement opportunities for Foundry Process Engineers?

Foundry Process Engineers can advance to roles such as Foundry Manager, Production Manager, or Quality Manager. With further education and experience, they can also specialize in areas such as research & development or process simulation.

What are the educational qualifications required to become a Foundry Process Engineer?

Foundry Process Engineers typically hold a bachelor’s or master’s degree in Mechanical Engineering, Materials Science, or a related field.

What are the key qualities of a successful Foundry Process Engineer?

Successful Foundry Process Engineers possess strong analytical and problem-solving skills, attention to detail, a commitment to quality, and the ability to work effectively in a team environment.