Are you a seasoned Foundry Technician seeking a new career path? Discover our professionally built Foundry Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

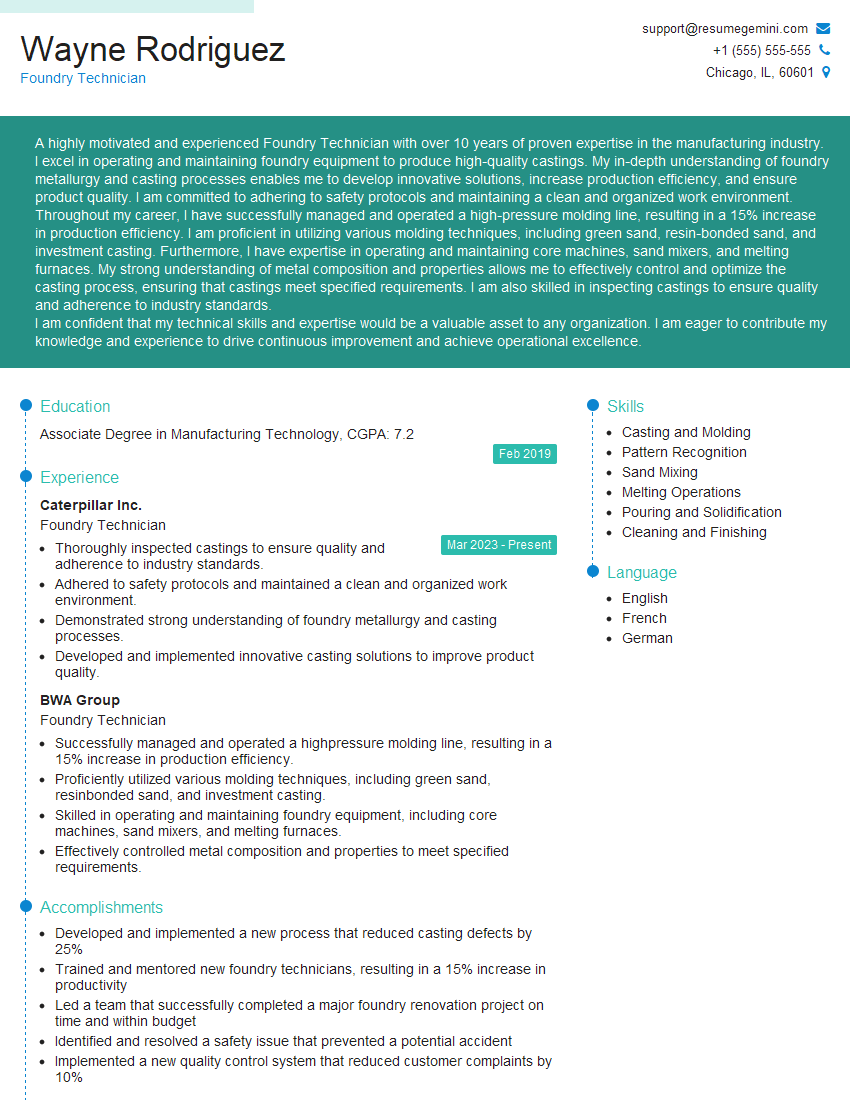

Wayne Rodriguez

Foundry Technician

Summary

A highly motivated and experienced Foundry Technician with over 10 years of proven expertise in the manufacturing industry. I excel in operating and maintaining foundry equipment to produce high-quality castings. My in-depth understanding of foundry metallurgy and casting processes enables me to develop innovative solutions, increase production efficiency, and ensure product quality. I am committed to adhering to safety protocols and maintaining a clean and organized work environment.

Throughout my career, I have successfully managed and operated a high-pressure molding line, resulting in a 15% increase in production efficiency. I am proficient in utilizing various molding techniques, including green sand, resin-bonded sand, and investment casting. Furthermore, I have expertise in operating and maintaining core machines, sand mixers, and melting furnaces. My strong understanding of metal composition and properties allows me to effectively control and optimize the casting process, ensuring that castings meet specified requirements. I am also skilled in inspecting castings to ensure quality and adherence to industry standards.

I am confident that my technical skills and expertise would be a valuable asset to any organization. I am eager to contribute my knowledge and experience to drive continuous improvement and achieve operational excellence.

Education

Associate Degree in Manufacturing Technology

February 2019

Skills

- Casting and Molding

- Pattern Recognition

- Sand Mixing

- Melting Operations

- Pouring and Solidification

- Cleaning and Finishing

Work Experience

Foundry Technician

- Thoroughly inspected castings to ensure quality and adherence to industry standards.

- Adhered to safety protocols and maintained a clean and organized work environment.

- Demonstrated strong understanding of foundry metallurgy and casting processes.

- Developed and implemented innovative casting solutions to improve product quality.

Foundry Technician

- Successfully managed and operated a highpressure molding line, resulting in a 15% increase in production efficiency.

- Proficiently utilized various molding techniques, including green sand, resinbonded sand, and investment casting.

- Skilled in operating and maintaining foundry equipment, including core machines, sand mixers, and melting furnaces.

- Effectively controlled metal composition and properties to meet specified requirements.

Accomplishments

- Developed and implemented a new process that reduced casting defects by 25%

- Trained and mentored new foundry technicians, resulting in a 15% increase in productivity

- Led a team that successfully completed a major foundry renovation project on time and within budget

- Identified and resolved a safety issue that prevented a potential accident

- Implemented a new quality control system that reduced customer complaints by 10%

Awards

- National Foundry Association Award for Excellence in Foundry Technology

- American Foundry Society Foundryman of the Year Award

- International Foundry Research Institute Award for Innovation in Foundry Science

Certificates

- OSHA 30-Hour Hazardous Waste Operations and Emergency Response (HAZWOPER)

- American Foundry Society (AFS) Quality Assurance and Control Technician

- NADCA Certified Metalcaster (CMc)

- AWS Certified Welding Inspector (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Foundry Technician

Quantify your accomplishments.

When describing your experience, use specific numbers and metrics to demonstrate your impact. For example, instead of saying “Increased production efficiency,” you could say “Increased production efficiency by 15%”.Highlight your skills and experience.

In your resume, be sure to list all of the relevant skills and experience you have that are applicable to the job you are applying for. For example, if you have experience with a particular type of foundry equipment, be sure to mention it.Proofread carefully.

Before submitting your resume, proofread it carefully for any errors. This includes checking for typos, grammatical errors, and formatting issues.Tailor your resume to the job you are applying for.

Take the time to tailor your resume to each job you apply for. This means highlighting the skills and experience that are most relevant to the job you are applying for.

Essential Experience Highlights for a Strong Foundry Technician Resume

- Operate and maintain foundry equipment, including core machines, sand mixers, and melting furnaces

- Control metal composition and properties to meet specified requirements

- Inspect castings to ensure quality and adherence to industry standards

- Adhere to safety protocols and maintain a clean and organized work environment

- Develop and implement innovative casting solutions to improve product quality

- Provide support to other foundry personnel as needed

- Participate in training and development programs to stay up-to-date on the latest foundry techniques

Frequently Asked Questions (FAQ’s) For Foundry Technician

What is the role of a Foundry Technician?

Foundry Technicians are responsible for operating and maintaining foundry equipment, controlling metal composition and properties, inspecting castings to ensure quality, adhering to safety protocols, and developing and implementing innovative casting solutions.

What are the qualifications for becoming a Foundry Technician?

Most Foundry Technicians have an Associate Degree in Manufacturing Technology or a related field. Additionally, they typically have several years of experience working in a foundry environment.

What are the key skills required for a Foundry Technician?

Foundry Technicians typically have strong skills in operating and maintaining foundry equipment, as well as in controlling metal composition and properties. Additionally, they are typically skilled in inspecting castings to ensure quality, adhering to safety protocols, and developing and implementing innovative casting solutions.

What are the career prospects for Foundry Technicians?

Foundry Technicians can advance to more senior positions, such as Foundry Supervisor or Foundry Manager. Additionally, they may choose to specialize in a particular area of foundry work, such as casting, molding, or finishing.

What is the work environment of a Foundry Technician like?

Foundry Technicians typically work in a foundry environment, which can be hot, noisy, and dirty. They may also be exposed to hazardous chemicals and materials.

What are the safety precautions that Foundry Technicians must take?

Foundry Technicians must take a number of safety precautions, such as wearing protective clothing and equipment, following safe work practices, and being aware of potential hazards.

What are the challenges of working as a Foundry Technician?

The challenges of working as a Foundry Technician include working in a hot, noisy, and dirty environment, being exposed to hazardous chemicals and materials, and having to follow strict safety protocols.