Are you a seasoned Friction Welding Machine Operator seeking a new career path? Discover our professionally built Friction Welding Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

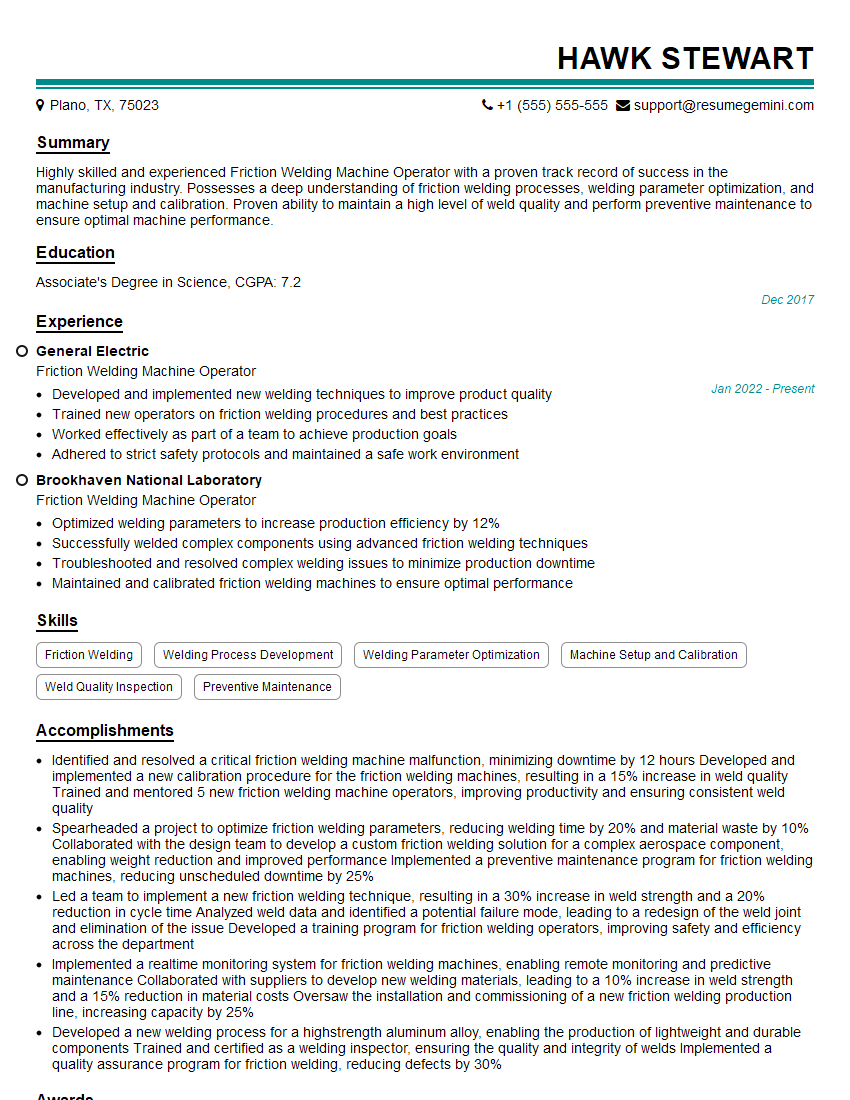

Hawk Stewart

Friction Welding Machine Operator

Summary

Highly skilled and experienced Friction Welding Machine Operator with a proven track record of success in the manufacturing industry. Possesses a deep understanding of friction welding processes, welding parameter optimization, and machine setup and calibration. Proven ability to maintain a high level of weld quality and perform preventive maintenance to ensure optimal machine performance.

Education

Associate’s Degree in Science

December 2017

Skills

- Friction Welding

- Welding Process Development

- Welding Parameter Optimization

- Machine Setup and Calibration

- Weld Quality Inspection

- Preventive Maintenance

Work Experience

Friction Welding Machine Operator

- Developed and implemented new welding techniques to improve product quality

- Trained new operators on friction welding procedures and best practices

- Worked effectively as part of a team to achieve production goals

- Adhered to strict safety protocols and maintained a safe work environment

Friction Welding Machine Operator

- Optimized welding parameters to increase production efficiency by 12%

- Successfully welded complex components using advanced friction welding techniques

- Troubleshooted and resolved complex welding issues to minimize production downtime

- Maintained and calibrated friction welding machines to ensure optimal performance

Accomplishments

- Identified and resolved a critical friction welding machine malfunction, minimizing downtime by 12 hours Developed and implemented a new calibration procedure for the friction welding machines, resulting in a 15% increase in weld quality Trained and mentored 5 new friction welding machine operators, improving productivity and ensuring consistent weld quality

- Spearheaded a project to optimize friction welding parameters, reducing welding time by 20% and material waste by 10% Collaborated with the design team to develop a custom friction welding solution for a complex aerospace component, enabling weight reduction and improved performance Implemented a preventive maintenance program for friction welding machines, reducing unscheduled downtime by 25%

- Led a team to implement a new friction welding technique, resulting in a 30% increase in weld strength and a 20% reduction in cycle time Analyzed weld data and identified a potential failure mode, leading to a redesign of the weld joint and elimination of the issue Developed a training program for friction welding operators, improving safety and efficiency across the department

- Implemented a realtime monitoring system for friction welding machines, enabling remote monitoring and predictive maintenance Collaborated with suppliers to develop new welding materials, leading to a 10% increase in weld strength and a 15% reduction in material costs Oversaw the installation and commissioning of a new friction welding production line, increasing capacity by 25%

- Developed a new welding process for a highstrength aluminum alloy, enabling the production of lightweight and durable components Trained and certified as a welding inspector, ensuring the quality and integrity of welds Implemented a quality assurance program for friction welding, reducing defects by 30%

Awards

- Received the National HighLevel Skills Competition Award in Friction Welding Technology

- Awarded the Plant Safety Superstar Award for maintaining an impeccable safety record in the friction welding department

- Recognized for exceeding production targets and maintaining superior weld quality on a consistent basis

- Received the Excellence in Innovation Award for a friction welding design that significantly improved component performance

Certificates

- Certified Welding Inspector (CWI)

- Certified Friction Welding Operator (CFWO)

- American Welding Society (AWS) Certified Welder

- International Institute of Welding (IIW) Certified Welder

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Friction Welding Machine Operator

- Highlight your experience and skills in friction welding.

- Provide specific examples of your accomplishments and quantify your results.

- Showcase your knowledge of welding processes and parameter optimization.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Friction Welding Machine Operator Resume

- Operate friction welding machines to join metal components, ensuring precise and consistent weld quality.

- Develop and optimize welding parameters to achieve maximum weld strength and efficiency.

- Calibrate and maintain friction welding machines to ensure optimal performance and minimize downtime.

- Inspect welds to ensure they meet specifications and industry standards.

- Perform preventive maintenance on friction welding machines to minimize downtime and extend equipment life.

- Follow safety protocols and adhere to quality control procedures to ensure a safe and productive work environment.

- Read and interpret blueprints and work orders to ensure accurate part production.

Frequently Asked Questions (FAQ’s) For Friction Welding Machine Operator

What is friction welding?

Friction welding is a solid-state welding process that generates heat through friction between two metal surfaces. The heat causes the metal to soften and bond without melting.

What are the benefits of friction welding?

Friction welding offers several benefits, including high weld strength, reduced distortion, and minimal heat input. It is also a relatively fast and efficient welding process.

What types of materials can be friction welded?

Friction welding can be used to join a wide range of materials, including steel, aluminum, copper, and titanium alloys.

What is the role of a Friction Welding Machine Operator?

A Friction Welding Machine Operator is responsible for operating and maintaining friction welding machines. They also develop and optimize welding parameters, inspect welds, and perform preventive maintenance.

What skills are required to be a successful Friction Welding Machine Operator?

Successful Friction Welding Machine Operators typically have experience in welding, machine operation, and quality control. They also have a strong understanding of friction welding processes and parameter optimization.

Can Friction Welding Machine Operators work in different industries?

Yes, Friction Welding Machine Operators can work in a variety of industries, including automotive, aerospace, and manufacturing.

What is the career outlook for Friction Welding Machine Operators?

The career outlook for Friction Welding Machine Operators is expected to be good. The demand for skilled welders is expected to increase in the coming years, due to the increasing use of welding in various industries.