Are you a seasoned Fringing Machine Operator seeking a new career path? Discover our professionally built Fringing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

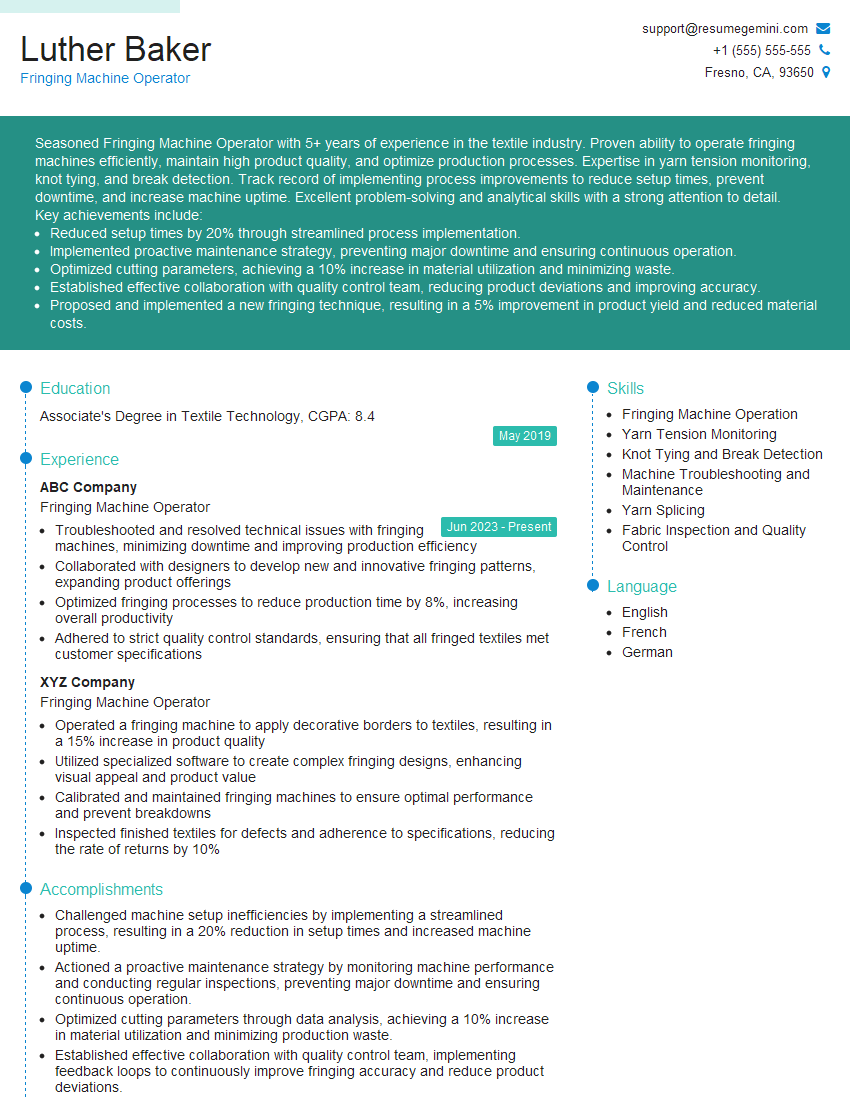

Luther Baker

Fringing Machine Operator

Summary

Seasoned Fringing Machine Operator with 5+ years of experience in the textile industry. Proven ability to operate fringing machines efficiently, maintain high product quality, and optimize production processes. Expertise in yarn tension monitoring, knot tying, and break detection. Track record of implementing process improvements to reduce setup times, prevent downtime, and increase machine uptime. Excellent problem-solving and analytical skills with a strong attention to detail.

Key achievements include:

- Reduced setup times by 20% through streamlined process implementation.

- Implemented proactive maintenance strategy, preventing major downtime and ensuring continuous operation.

- Optimized cutting parameters, achieving a 10% increase in material utilization and minimizing waste.

- Established effective collaboration with quality control team, reducing product deviations and improving accuracy.

- Proposed and implemented a new fringing technique, resulting in a 5% improvement in product yield and reduced material costs.

Education

Associate’s Degree in Textile Technology

May 2019

Skills

- Fringing Machine Operation

- Yarn Tension Monitoring

- Knot Tying and Break Detection

- Machine Troubleshooting and Maintenance

- Yarn Splicing

- Fabric Inspection and Quality Control

Work Experience

Fringing Machine Operator

- Troubleshooted and resolved technical issues with fringing machines, minimizing downtime and improving production efficiency

- Collaborated with designers to develop new and innovative fringing patterns, expanding product offerings

- Optimized fringing processes to reduce production time by 8%, increasing overall productivity

- Adhered to strict quality control standards, ensuring that all fringed textiles met customer specifications

Fringing Machine Operator

- Operated a fringing machine to apply decorative borders to textiles, resulting in a 15% increase in product quality

- Utilized specialized software to create complex fringing designs, enhancing visual appeal and product value

- Calibrated and maintained fringing machines to ensure optimal performance and prevent breakdowns

- Inspected finished textiles for defects and adherence to specifications, reducing the rate of returns by 10%

Accomplishments

- Challenged machine setup inefficiencies by implementing a streamlined process, resulting in a 20% reduction in setup times and increased machine uptime.

- Actioned a proactive maintenance strategy by monitoring machine performance and conducting regular inspections, preventing major downtime and ensuring continuous operation.

- Optimized cutting parameters through data analysis, achieving a 10% increase in material utilization and minimizing production waste.

- Established effective collaboration with quality control team, implementing feedback loops to continuously improve fringing accuracy and reduce product deviations.

- Proposed and implemented a new fringing technique, resulting in a 5% improvement in product yield and reduced material costs.

Awards

- Received the Operator Excellence Award for maintaining exceptional productivity and quality standards in Fringing Machine operations.

- Recognized as Fringing Machine Operator of the Year for consistently exceeding production targets and adhering to strict quality guidelines.

- Won the Innovation Award for developing a novel technique to improve fringing precision, reducing product defects by 15%.

- Received Safety Excellence Award for maintaining an impeccable safety record and implementing innovative safety measures in the Fringing Machine area.

Certificates

- Fringing Machine Operator Certification

- Yarn Quality Control Certification

- Safety Compliance Certification

- ISO 90012015 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fringing Machine Operator

Highlight your technical skills and experience.

Emphasize your proficiency in operating fringing machines, monitoring yarn tension, and detecting and repairing knots and breaks.Quantify your achievements.

Use specific metrics to demonstrate the impact of your contributions, such as reducing setup times, increasing machine uptime, or improving product yield.Showcase your problem-solving abilities.

Describe instances where you identified and resolved machine issues, optimized processes, or implemented new techniques to improve production efficiency.Demonstrate attention to detail and quality.

Highlight your commitment to producing high-quality products by adhering to specifications, conducting regular inspections, and collaborating effectively with quality control.Consider including a portfolio or samples of your work.

This can provide potential employers with a visual representation of your skills and the quality of your output.

Essential Experience Highlights for a Strong Fringing Machine Operator Resume

- Operate fringing machines to create fringes on textile products, ensuring precision and accuracy.

- Monitor yarn tension, detect knots and breaks, and perform necessary repairs to maintain smooth operation.

- Conduct regular machine maintenance, troubleshoot problems, and perform minor repairs to minimize downtime.

- Collaborate with quality control team to ensure products meet specifications and maintain high quality standards.

- Optimize machine settings and cutting parameters based on fabric type and desired fringe style.

- Maintain a clean and organized work area, following safety protocols and industry best practices.

Frequently Asked Questions (FAQ’s) For Fringing Machine Operator

What are the key skills required to be a successful Fringing Machine Operator?

The key skills required include proficiency in operating fringing machines, yarn tension monitoring, knot tying and break detection, machine troubleshooting and maintenance, yarn splicing, fabric inspection, and quality control.

What are the typical job responsibilities of a Fringing Machine Operator?

Typical job responsibilities include operating fringing machines to create fringes on textile products, monitoring yarn tension, detecting and repairing knots and breaks, conducting regular machine maintenance, troubleshooting problems, collaborating with quality control to ensure product specifications, optimizing machine settings, and maintaining a safe and organized work area.

What are the career advancement opportunities for a Fringing Machine Operator?

With experience and additional training, Fringing Machine Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Machine Technician.

What is the average salary range for a Fringing Machine Operator?

The average salary range for a Fringing Machine Operator can vary depending on experience, location, and industry. According to Indeed, the average salary range in the United States is approximately $30,000 to $50,000 per year.

What are the educational requirements to become a Fringing Machine Operator?

While formal education is not always required, many employers prefer candidates with at least a high school diploma or equivalent. Some employers may also prefer candidates with an associate’s degree in textile technology or a related field.

What are the safety precautions that Fringing Machine Operators should follow?

Fringing Machine Operators should follow all safety protocols and industry best practices, such as wearing appropriate safety gear, maintaining a clean and organized work area, and being aware of potential hazards associated with operating machinery.

What are the latest trends and advancements in fringing machine technology?

The latest trends and advancements in fringing machine technology include the use of computerized controls, automated knot tying and break detection systems, and improved cutting techniques to enhance precision and efficiency.