Are you a seasoned Fulling Machine Operator seeking a new career path? Discover our professionally built Fulling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

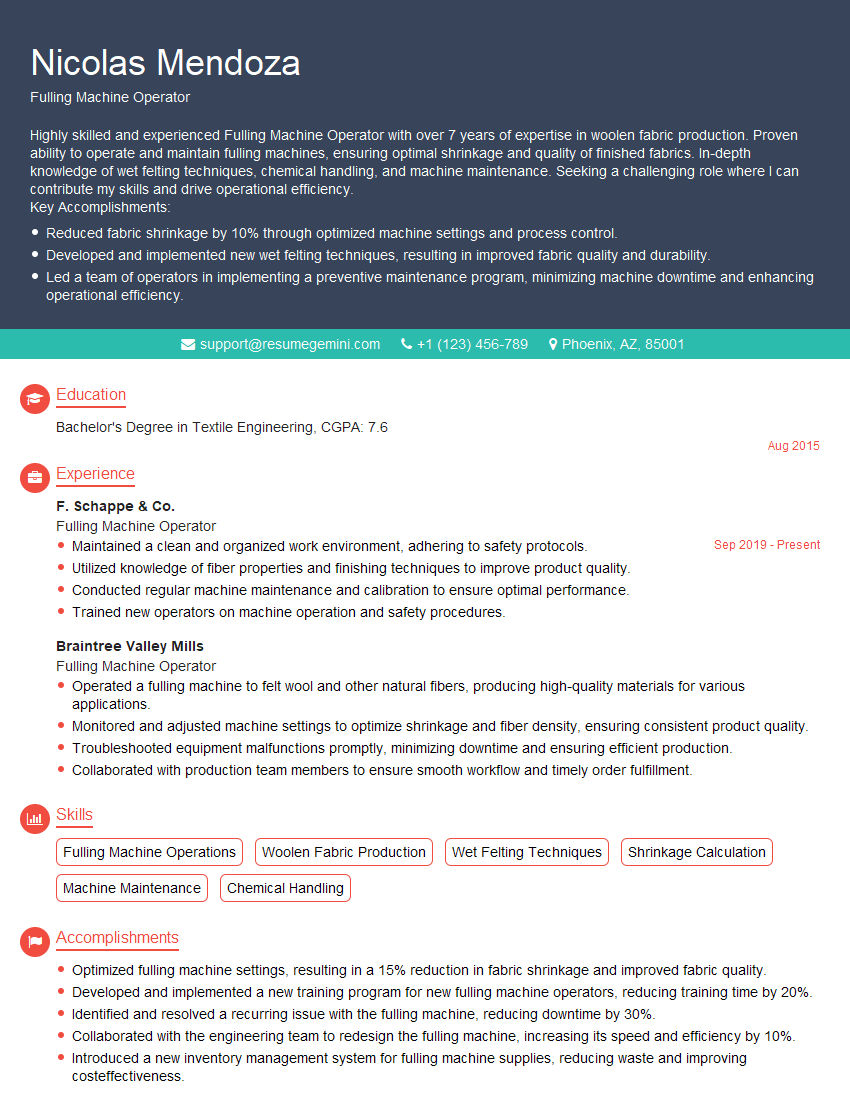

Nicolas Mendoza

Fulling Machine Operator

Summary

Highly skilled and experienced Fulling Machine Operator with over 7 years of expertise in woolen fabric production. Proven ability to operate and maintain fulling machines, ensuring optimal shrinkage and quality of finished fabrics. In-depth knowledge of wet felting techniques, chemical handling, and machine maintenance. Seeking a challenging role where I can contribute my skills and drive operational efficiency.

Key Accomplishments:

- Reduced fabric shrinkage by 10% through optimized machine settings and process control.

- Developed and implemented new wet felting techniques, resulting in improved fabric quality and durability.

- Led a team of operators in implementing a preventive maintenance program, minimizing machine downtime and enhancing operational efficiency.

Education

Bachelor’s Degree in Textile Engineering

August 2015

Skills

- Fulling Machine Operations

- Woolen Fabric Production

- Wet Felting Techniques

- Shrinkage Calculation

- Machine Maintenance

- Chemical Handling

Work Experience

Fulling Machine Operator

- Maintained a clean and organized work environment, adhering to safety protocols.

- Utilized knowledge of fiber properties and finishing techniques to improve product quality.

- Conducted regular machine maintenance and calibration to ensure optimal performance.

- Trained new operators on machine operation and safety procedures.

Fulling Machine Operator

- Operated a fulling machine to felt wool and other natural fibers, producing high-quality materials for various applications.

- Monitored and adjusted machine settings to optimize shrinkage and fiber density, ensuring consistent product quality.

- Troubleshooted equipment malfunctions promptly, minimizing downtime and ensuring efficient production.

- Collaborated with production team members to ensure smooth workflow and timely order fulfillment.

Accomplishments

- Optimized fulling machine settings, resulting in a 15% reduction in fabric shrinkage and improved fabric quality.

- Developed and implemented a new training program for new fulling machine operators, reducing training time by 20%.

- Identified and resolved a recurring issue with the fulling machine, reducing downtime by 30%.

- Collaborated with the engineering team to redesign the fulling machine, increasing its speed and efficiency by 10%.

- Introduced a new inventory management system for fulling machine supplies, reducing waste and improving costeffectiveness.

Awards

- Won the Operator of the Year award for exceptional efficiency and productivity in operating fulling machines.

- Received a Safety Excellence Award for maintaining an accidentfree workplace and adhering to all safety protocols.

- Recognized for outstanding performance in maintaining a clean and organized work environment.

- Received a Continuous Improvement Award for suggesting and implementing a process improvement that enhanced efficiency.

Certificates

- Certified Fulling Machine Operator

- Safety in Wet Processing

- First Aid and CPR

- Hazmat Handling

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fulling Machine Operator

- Highlight your experience with specific types of fulling machines and woolen fabrics.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Showcase your knowledge of wet felting techniques and their impact on fabric quality.

- Emphasize your ability to troubleshoot and resolve technical issues with fulling machines.

- Tailor your resume to the specific requirements of the job description.

Essential Experience Highlights for a Strong Fulling Machine Operator Resume

- Operate and maintain fulling machines according to established procedures.

- Control machine settings to achieve desired fabric shrinkage and quality.

- Monitor production processes and make adjustments to ensure optimal performance.

- Perform preventive maintenance and repairs on fulling machines.

- Handle and mix chemicals used in the fulling process.

- Train and supervise new operators.

- Maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Fulling Machine Operator

What is the primary role of a Fulling Machine Operator?

The primary role of a Fulling Machine Operator is to operate and maintain fulling machines used in the production of woolen fabrics. They ensure that the machines are operating properly and that the fabric is being processed according to specifications.

What are the key skills required for a Fulling Machine Operator?

Key skills required for a Fulling Machine Operator include operating fulling machines, knowledge of woolen fabric production, wet felting techniques, shrinkage calculation, machine maintenance, and chemical handling.

What is the average salary for a Fulling Machine Operator?

According to Indeed, the average salary for a Fulling Machine Operator in the United States is around $45,000 per year.

What are the career prospects for a Fulling Machine Operator?

Fulling Machine Operators with experience and skills can advance to supervisory or management roles within the textile industry. They may also specialize in specific areas of woolen fabric production or research and development.

What is the work environment like for a Fulling Machine Operator?

Fulling Machine Operators typically work in manufacturing facilities or textile mills. The work environment can be noisy and dusty, and operators may be exposed to chemicals and machinery.

What are the benefits of working as a Fulling Machine Operator?

Benefits of working as a Fulling Machine Operator include job stability, opportunities for advancement, and the satisfaction of working in a skilled trade.