Are you a seasoned Fulling Mill Operator seeking a new career path? Discover our professionally built Fulling Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

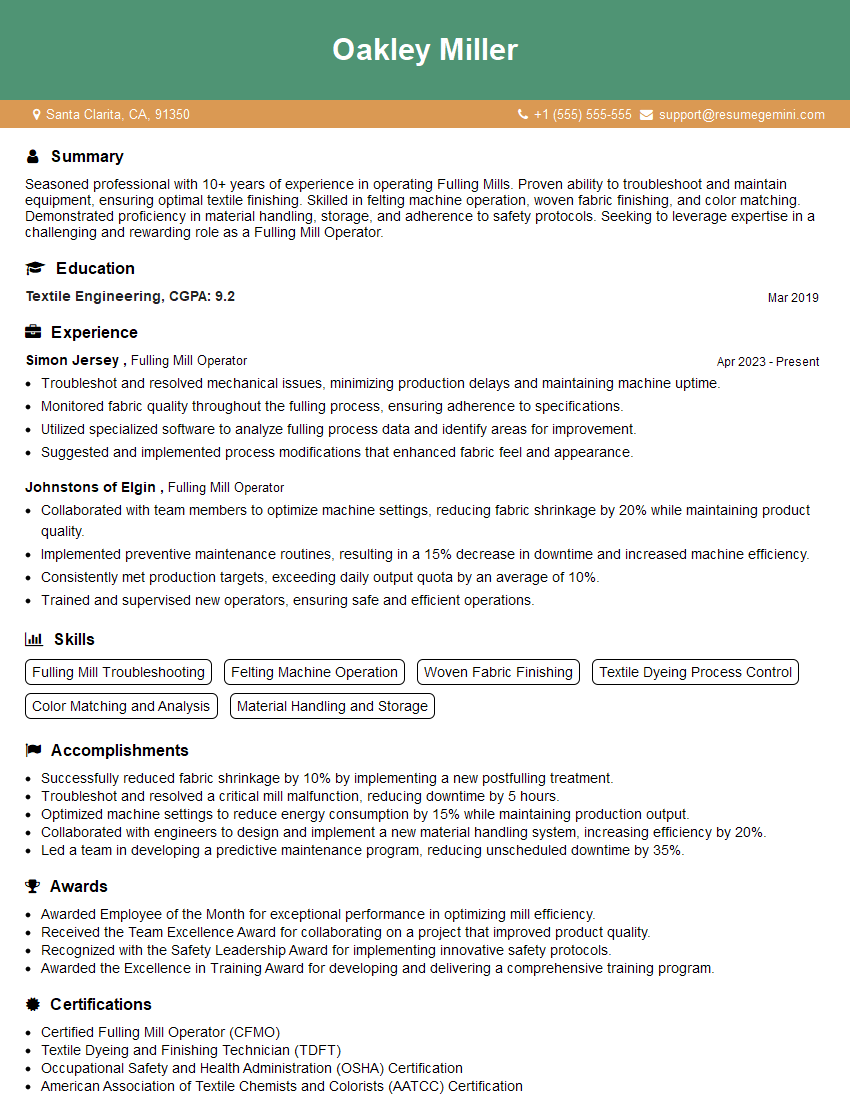

Oakley Miller

Fulling Mill Operator

Summary

Seasoned professional with 10+ years of experience in operating Fulling Mills. Proven ability to troubleshoot and maintain equipment, ensuring optimal textile finishing. Skilled in felting machine operation, woven fabric finishing, and color matching. Demonstrated proficiency in material handling, storage, and adherence to safety protocols. Seeking to leverage expertise in a challenging and rewarding role as a Fulling Mill Operator.

Education

Textile Engineering

March 2019

Skills

- Fulling Mill Troubleshooting

- Felting Machine Operation

- Woven Fabric Finishing

- Textile Dyeing Process Control

- Color Matching and Analysis

- Material Handling and Storage

Work Experience

Fulling Mill Operator

- Troubleshot and resolved mechanical issues, minimizing production delays and maintaining machine uptime.

- Monitored fabric quality throughout the fulling process, ensuring adherence to specifications.

- Utilized specialized software to analyze fulling process data and identify areas for improvement.

- Suggested and implemented process modifications that enhanced fabric feel and appearance.

Fulling Mill Operator

- Collaborated with team members to optimize machine settings, reducing fabric shrinkage by 20% while maintaining product quality.

- Implemented preventive maintenance routines, resulting in a 15% decrease in downtime and increased machine efficiency.

- Consistently met production targets, exceeding daily output quota by an average of 10%.

- Trained and supervised new operators, ensuring safe and efficient operations.

Accomplishments

- Successfully reduced fabric shrinkage by 10% by implementing a new postfulling treatment.

- Troubleshot and resolved a critical mill malfunction, reducing downtime by 5 hours.

- Optimized machine settings to reduce energy consumption by 15% while maintaining production output.

- Collaborated with engineers to design and implement a new material handling system, increasing efficiency by 20%.

- Led a team in developing a predictive maintenance program, reducing unscheduled downtime by 35%.

Awards

- Awarded Employee of the Month for exceptional performance in optimizing mill efficiency.

- Received the Team Excellence Award for collaborating on a project that improved product quality.

- Recognized with the Safety Leadership Award for implementing innovative safety protocols.

- Awarded the Excellence in Training Award for developing and delivering a comprehensive training program.

Certificates

- Certified Fulling Mill Operator (CFMO)

- Textile Dyeing and Finishing Technician (TDFT)

- Occupational Safety and Health Administration (OSHA) Certification

- American Association of Textile Chemists and Colorists (AATCC) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fulling Mill Operator

- Quantify your accomplishments using specific metrics to demonstrate your impact.

- Highlight your troubleshooting abilities and provide examples of complex issues you resolved.

- Showcase your knowledge of textile finishing techniques and color matching principles.

- Emphasize your attention to detail and commitment to quality assurance.

Essential Experience Highlights for a Strong Fulling Mill Operator Resume

- Operate Fulling Mills to felt and finish woven fabrics

- Monitor and adjust machine parameters to achieve desired fabric characteristics

- Troubleshoot and resolve operational issues to minimize downtime

- Maintain a clean and safe work environment, adhering to safety regulations

- Handle and store materials effectively to prevent damage and ensure efficient production

- Collaborate with team members to optimize production processes

- Stay updated on industry best practices and technological advancements

Frequently Asked Questions (FAQ’s) For Fulling Mill Operator

What is the role of a Fulling Mill Operator?

A Fulling Mill Operator is responsible for operating and maintaining Fulling Mills, which are machines used to felt and finish woven fabrics. They adjust machine settings, monitor production, troubleshoot issues, and ensure the efficient operation of the equipment.

What skills are required to be a successful Fulling Mill Operator?

Successful Fulling Mill Operators typically possess a combination of technical skills, such as machine operation and maintenance, and an understanding of textile finishing processes. They should also have strong problem-solving abilities and attention to detail.

What industries employ Fulling Mill Operators?

Fulling Mill Operators are primarily employed in the textile industry, specifically in mills that produce woven fabrics. They may also find opportunities in related industries, such as garment manufacturing and home textiles.

What is the career path for a Fulling Mill Operator?

With experience and additional training, Fulling Mill Operators can advance to supervisory roles, such as Production Supervisor or Quality Control Inspector. They may also specialize in specific areas of textile finishing, such as color matching or fabric testing.

What is the average salary for a Fulling Mill Operator?

According to Indeed, the average salary for a Fulling Mill Operator in the United States is around $25,000 per year. However, salaries can vary depending on experience, location, and industry.